Active functional polymer surfactant for oil displacement and preparation method thereof

A functional, polysurfactant technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of improving thermal stability, enhancing solubility, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

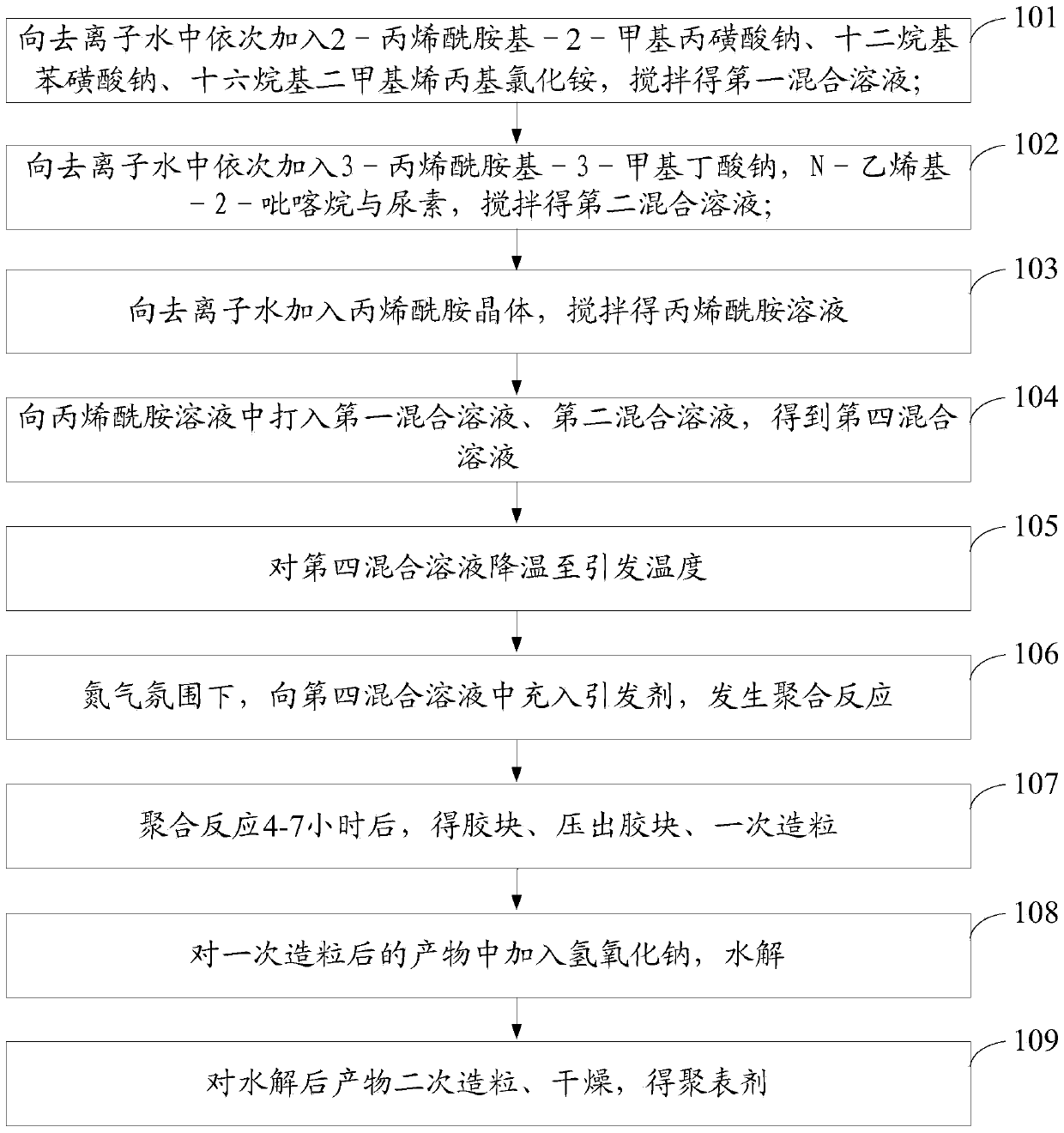

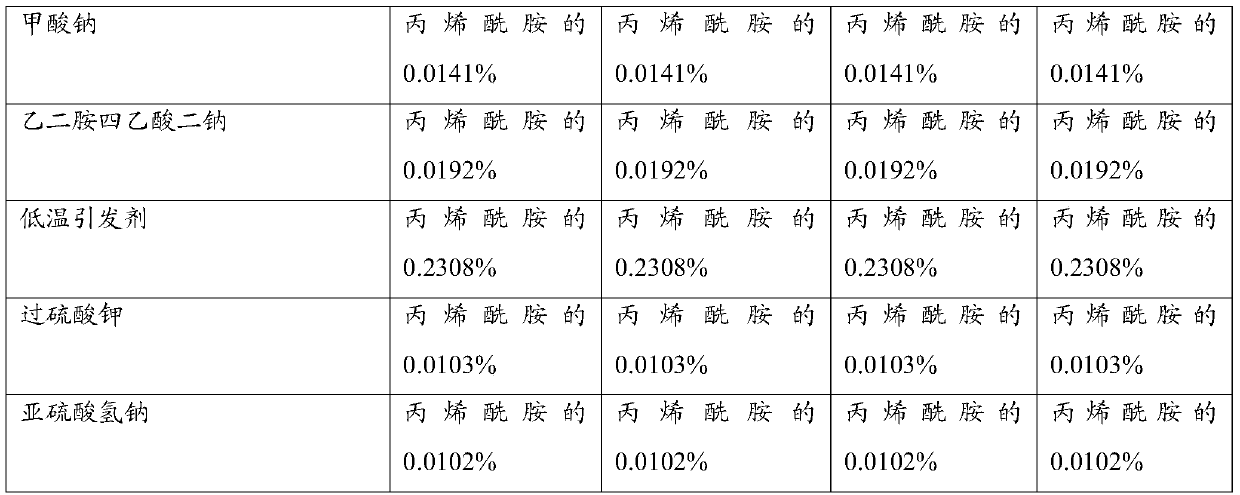

[0032] The preparation method of the above-mentioned active functional polysurfactant for oil displacement, such as figure 1 shown, including:

[0033]Step 101, adding sodium 2-acrylamido-2-methylpropanesulfonate, sodium dodecylbenzenesulfonate, and hexadecyldimethylallyl ammonium chloride to the first deionized water in sequence, and stirring Obtain the first mixed solution; during the addition process, after the last raw material is dissolved, add the next raw material;

[0034] Step 102, adding 3-acrylamido-3-methylsodium butyrate, N-vinyl-2-pyrrolidone and urea to the second deionized water in sequence, and stirring to obtain a second mixed solution; during the adding process, When the previous raw material is dissolved, add the next raw material;

[0035] Step 103, adding acrylamide crystals to the third deionized water, and stirring to obtain an acrylamide solution;

[0036] Step 104, pouring the first mixed solution and the second mixed solution into the acrylamide s...

Embodiment 1

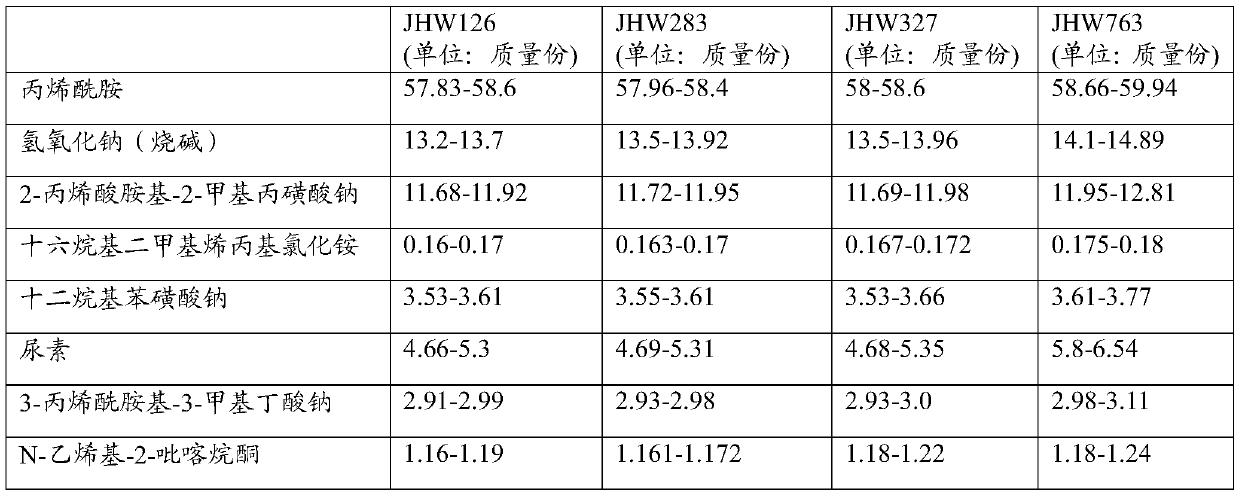

[0068] Preparation of JHW126 polysurfactant

[0069]In the batching tank M, add 4.09 times of deionized water to 11.70 kg of sodium 2-acrylamido-2-methylpropanesulfonate, 3.60 kg of sodium dodecylbenzenesulfonate and hexadecyldimethylallyl The sum of the quantity of ammonium chloride 0.165 kilograms, then start to stir, add above-mentioned raw material in tank M successively, will add latter raw material again after former raw material dissolves completely, stir until raw material dissolves completely.

[0070] Add 3.45 times the sum of 2.96 kg of 3-acrylamido-3-methyl sodium butyrate, 1.17 kg of N-vinyl-2-pyrrolidone and 4.98 kg of urea to the batching tank N. Then start stirring, and add the above-mentioned raw materials into the tank N one by one. After the former raw material is completely dissolved, add the latter raw material, and stir until the raw material is completely dissolved. .

[0071] Add 2.35 times the amount of deionized water to 57.99 kg of acrylamide cryst...

Embodiment 2

[0077] Preparation of JHW126 polysurfactant

[0078] In the batching tank M, add 4.09 times of deionized water to 11.87 kg of sodium 2-acrylamido-2-methylpropanesulfonate, 3.60 kg of sodium dodecylbenzenesulfonate and hexadecyldimethylallyl The sum of the quantity of ammonium chloride 0.168 kilograms, then start to stir, add above-mentioned raw material in tank M successively, will add latter kind of raw material again after former raw material dissolves completely, stir until raw material dissolves completely.

[0079] Add 3.45 times the sum of 2.98 kg of 3-acrylamido-3-methyl sodium butyrate, 1.186 kg of N-vinyl-2-pyrrolidone and 5.2 kg of urea into the batching tank N. Then start stirring, and add the above-mentioned raw materials into the tank N one by one. After the former raw material is completely dissolved, add the latter raw material, and stir until the raw material is completely dissolved.

[0080] Add 2.35 times the amount of deionized water to 58.1 kg of acrylamid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com