Construction method of hydraulic punching and pre-splitting blasting combined anti-reflection drainage system in borehole

A technology of hydraulic punching and pre-splitting blasting, which is applied to earth drilling, mining fluids, mining equipment, etc. It can solve the problems of large drilling construction, small effective range of influence, and complicated construction procedures, so as to reduce gas safety. The effects of reducing hidden dangers, improving the drainage effect, and shortening the total gas drainage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

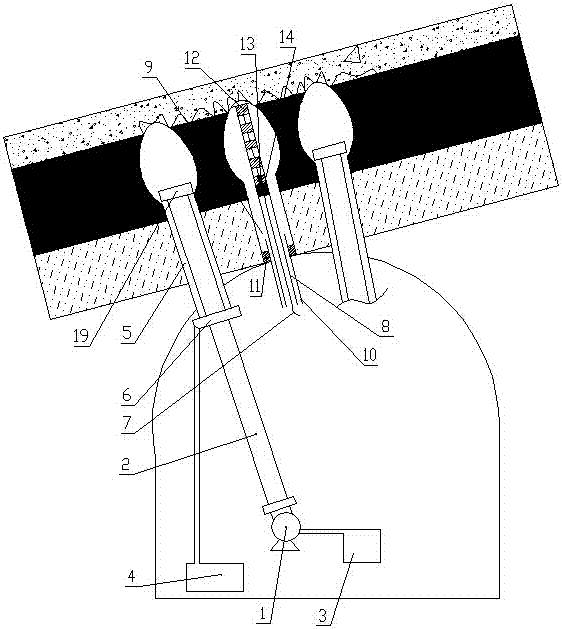

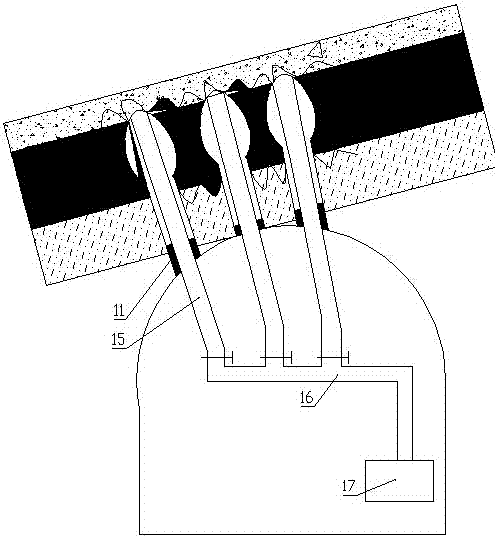

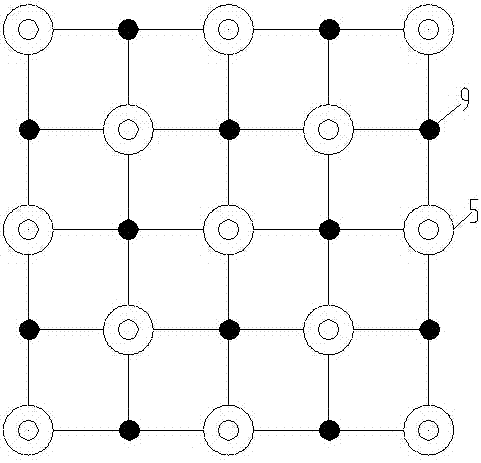

[0027] Such as Figure 1-5 As shown, the construction method of the hydraulic punching and pre-split blasting combined anti-reflection drainage system in the borehole of the present invention, the hydraulic punching and pre-split blasting combined anti-reflection drainage system in the borehole includes hydraulic punching device, pre-split A blasting device and a gas extraction device; a number of blasting boreholes 9 and punching boreholes 5 are staggered in the direction of the coal seam in the coal seam floor drainage roadway;

[0028] The hydraulic punching device includes a drilling machine 1, a drill pipe 2, a drill bit 19, a high-pressure water injection pump 3 and a water gas separator 4. The drill rod 2 is connected to the water inlet, the lower end of the drill rod 2 is connected with the power output end of the drilling machine 1, the upper end of the drill rod 2 is inserted into the punching hole 5 and fixedly connected with the drill bit 19, and the punching hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com