Efficient energy-saving and emission-reduction sub-system of automobile

A technology for system temperature and automobile exhaust, which is applied to automobiles with significant energy saving, environmental protection subsystems, and emission reduction fields, and can solve problems such as mixing, waste, and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

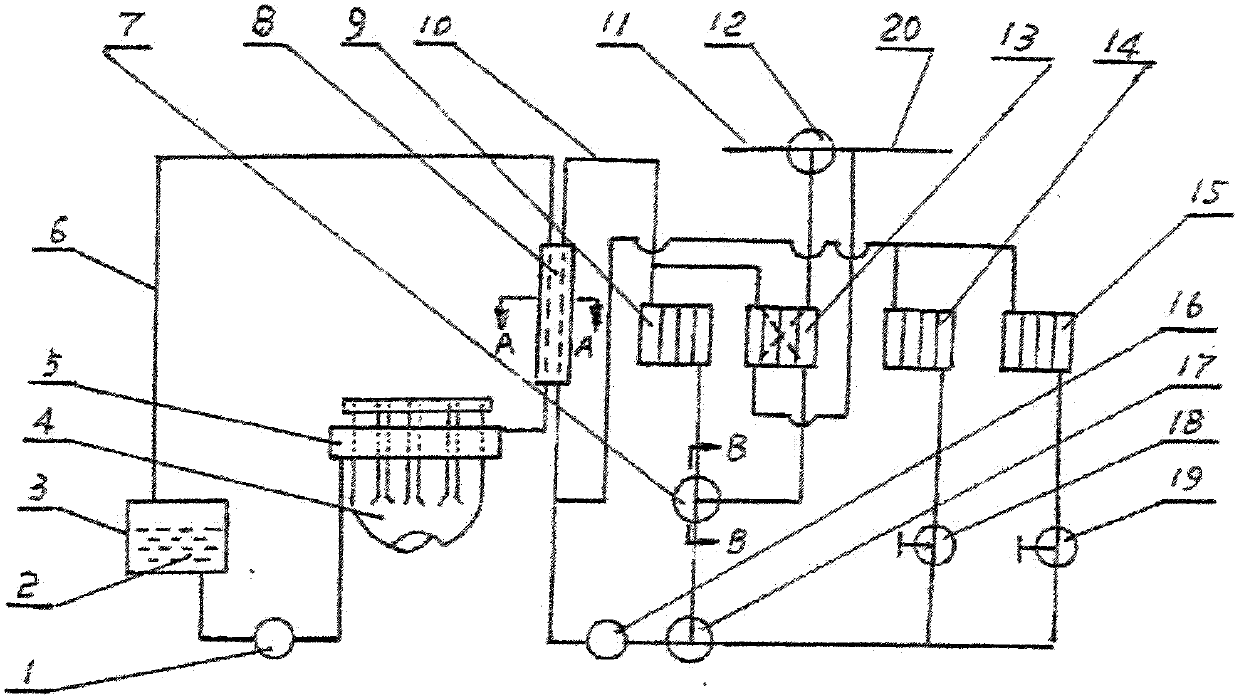

[0013] The present invention has three combinations:

[0014] The first type: Vehicles without the whole vehicle heating function: consisting of liquid pump 1, heat transfer medium 2, storage box 3, waste heat collector 5, coolant heat exchanger 8, electric three-way proportional valve 7, double-circuit air heat exchange 13, electromagnetic three-way valve 12, condenser and its fan 14 (note: original car parts), electric ball valve 18, relay ①, relay ②, temperature adjustment module ECU, gear switch, temperature digital display. 10 seconds after the engine is started, the system temperature measured by the coolant temperature sensor (which can be shared with the original car) is lower than 84°C and maintained for 10 seconds, the liquid pump 1 starts to rotate, and the heat transfer medium 2 flows through the liquid pump from the storage box 3 1. The waste heat collector 5 and the coolant heat exchanger 8 return to the storage box 3, and the waste heat collected by the waste he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com