Titanium dioxide nanorod array/silicon heterojunction-based ultraviolet light detector and preparation method thereof

A nanorod array, titanium dioxide technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as low ability to absorb ultraviolet rays, achieve short recovery time, low energy consumption, and sensitivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

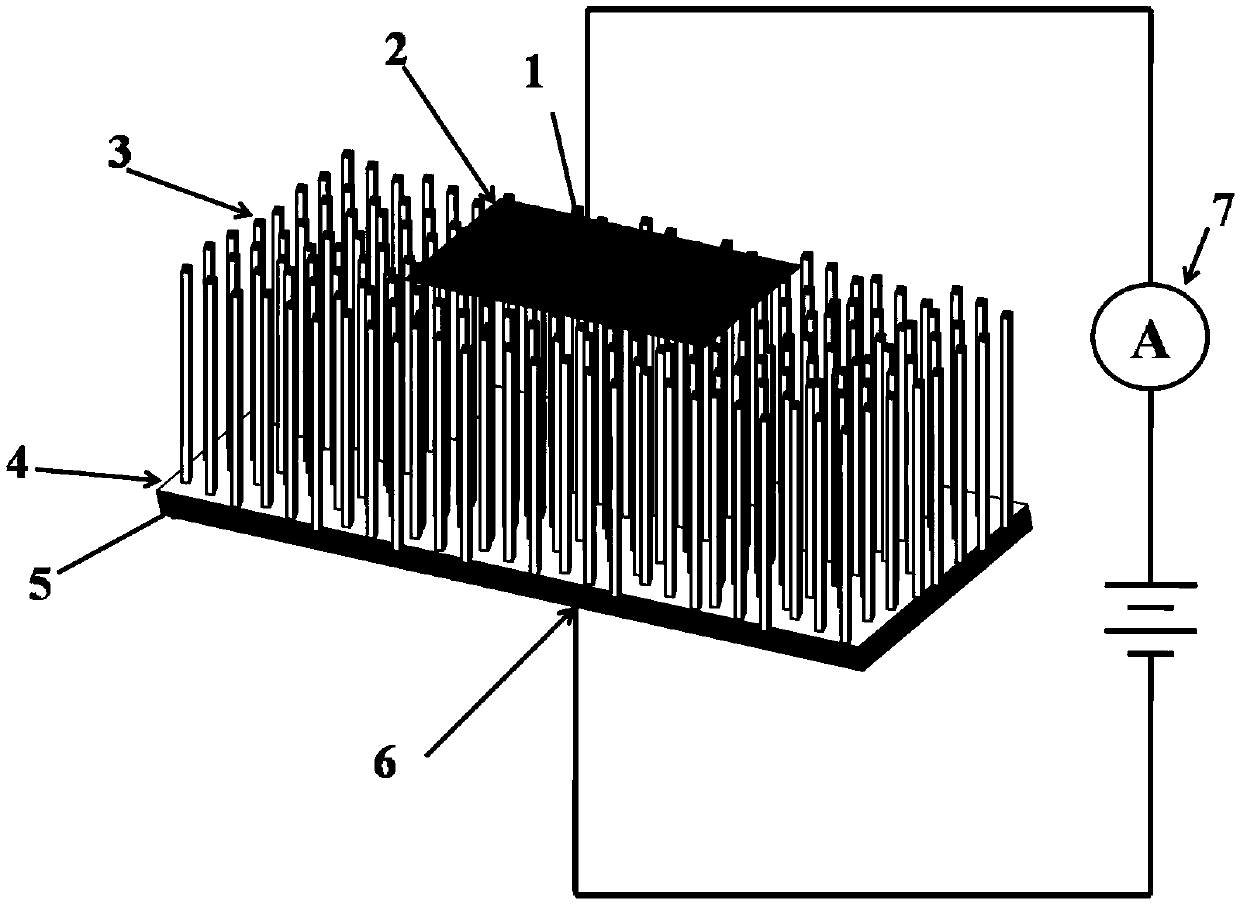

[0025] We selected an n-type monocrystalline silicon wafer with a thickness of 0.5 mm as the substrate, and retained its natural oxide layer. Clean the silicon wafer in ultrasonic wave with deionized water for 15 minutes, then clean the silicon wafer in ultrasonic wave with acetone for 20 hours, and finally clean the silicon wafer with absolute ethanol for 20 minutes. After drying, repeat the above cleaning process again.

[0026]Dry the cleaned n-type silicon substrate and place it in a spin-coating chamber. Spin-coat the titanium dioxide seed layer under the background of continuously flowing nitrogen gas. Put the titanium dioxide nano-film / silicon substrate prepared by the spin coating method into a tubular resistance furnace for annealing in a nitrogen atmosphere at a temperature of 800 degrees Celsius, with a heating rate of 4 degrees Celsius per minute, and keep at 800 degrees Celsius for 2 hours. Put the annealed titanium dioxide nanofilm / silicon substrate into polytet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com