IGBT protection circuit and method used in AC argon arc welding machine

A protection circuit and argon arc welding machine technology, applied in the field of AC argon arc welding, can solve the problems of unsatisfactory IGBT overcurrent capability, influence of machine reliability judgment, inability to automatically recover, etc., to achieve low price, prevent overheating damage, prevent The effect of misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

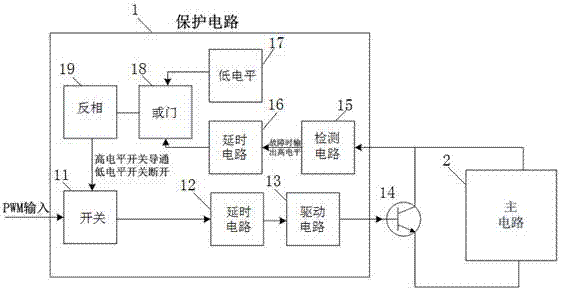

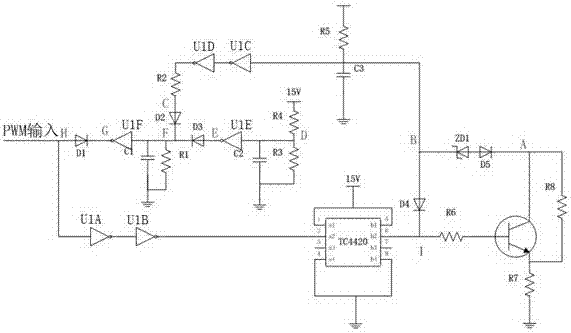

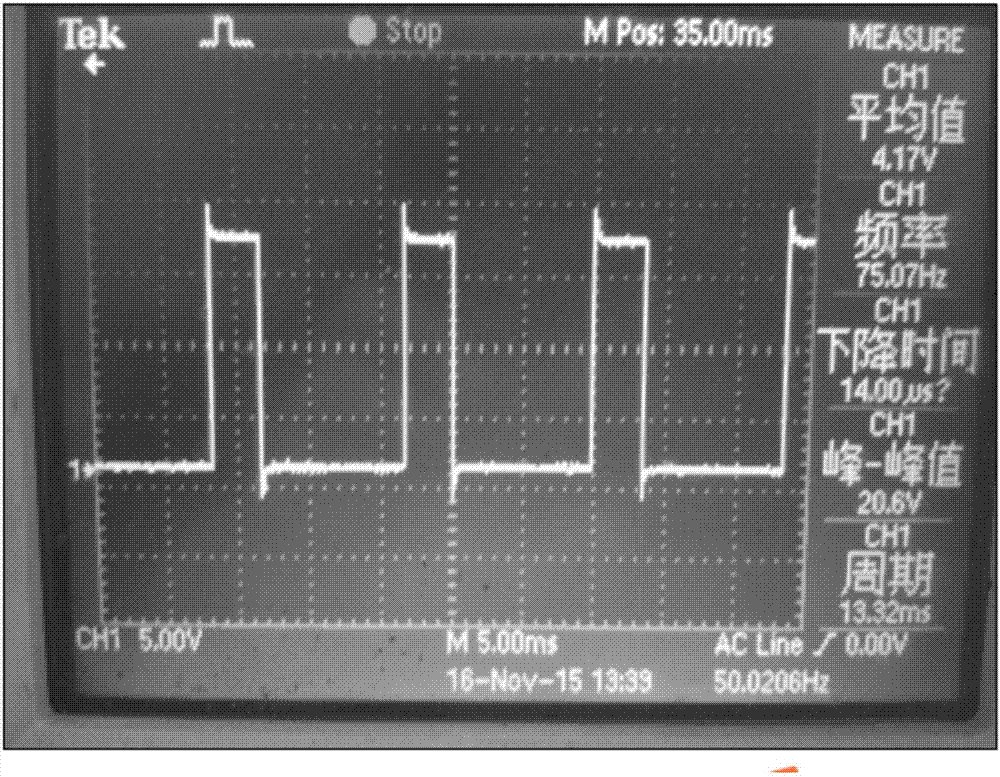

[0025] The purpose of this invention is to protect the IGBT when the AC argon arc welding machine is overcurrent. When the collector current of the IGBT exceeds the rated value, it does not directly cut off the IGBT gate control signal when a short circuit is detected, but continuously scans to detect the fault Whether it is eliminated, once the fault or interference is eliminated, the collector current returns to the rated range, and the circuit can return to normal working condition. The control method for intermittently cutting off the control signal provided by the present invention is the so-called "hiccup protection method". This is a vivid description of whether the system judges whether there is a fault, that is, whether the IGBT collector current is overcurrent. The control signal of the protection circuit is constantly testing. If t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com