In-situ emulsification modification method for nano calcium carbonate for polyurethane sealant

A technology of polyurethane sealant and nano-calcium carbonate, which is applied in the direction of chemical instruments and methods, polyurea/polyurethane adhesives, adhesives, etc., can solve the problems that the modification process cannot be refined economically and effectively, and the formation of inclusions can be reduced. Achieve the effects of easy industrial promotion, reduced generation, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

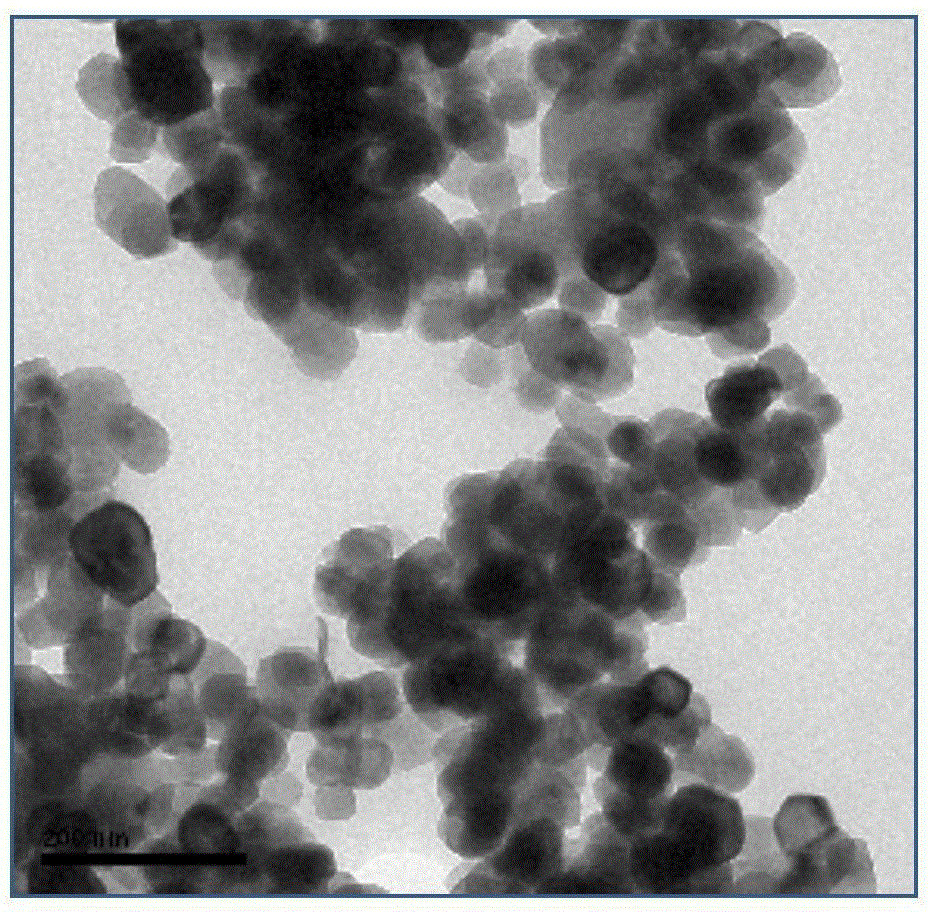

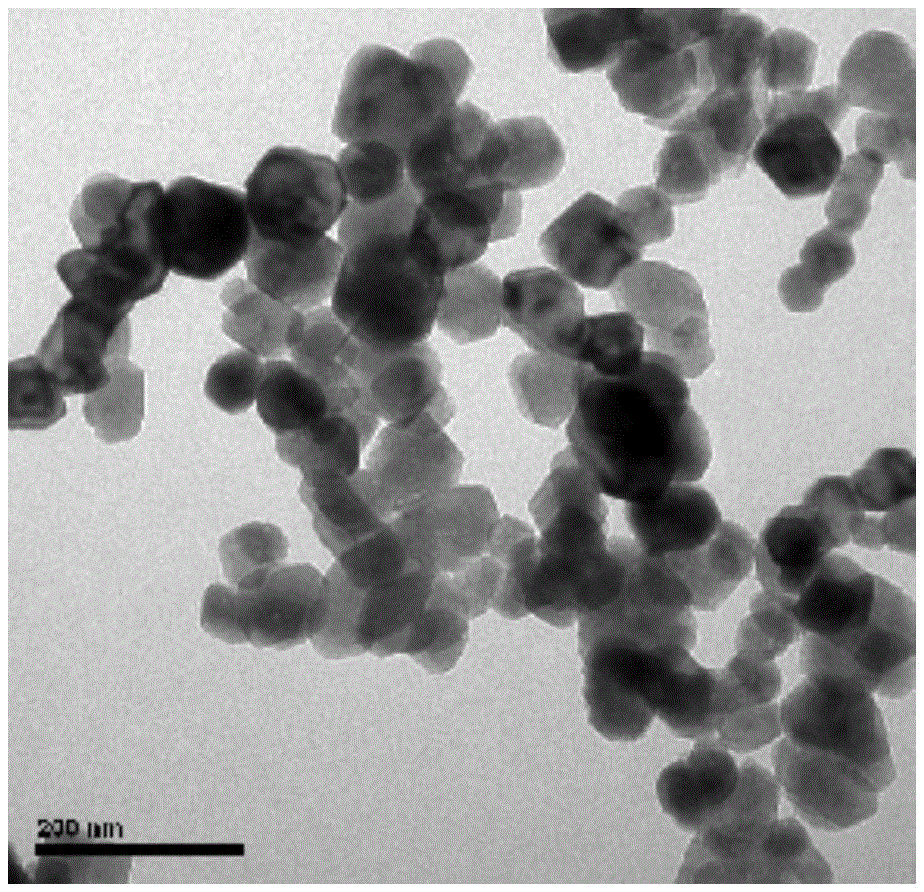

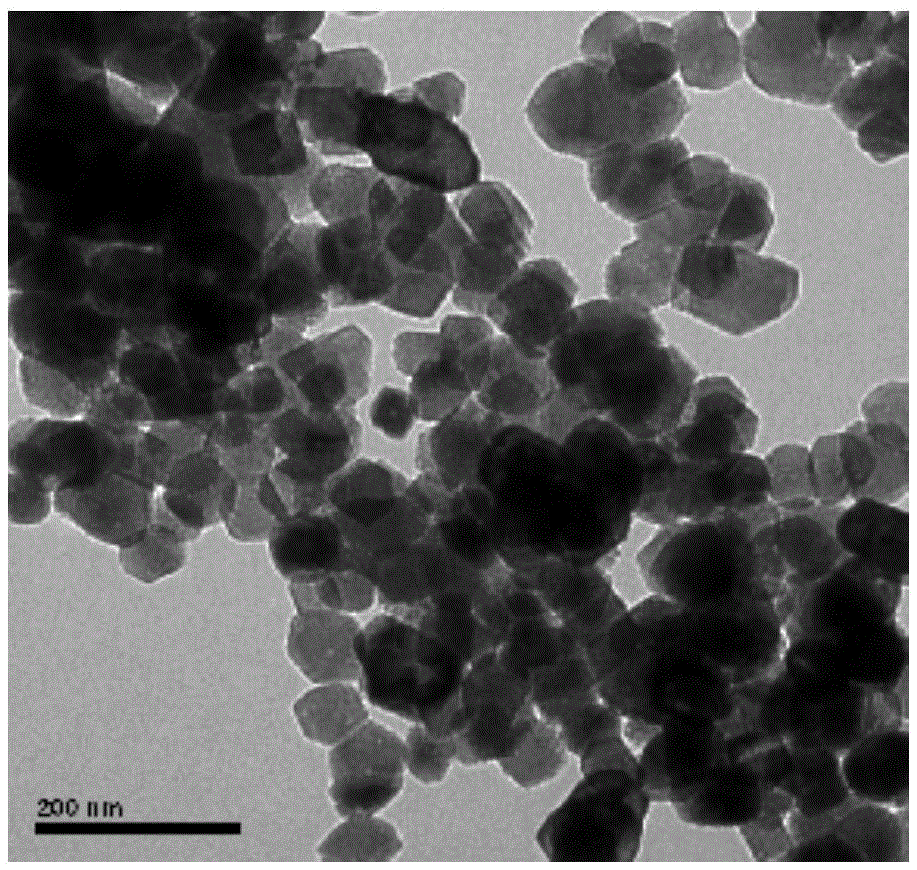

Image

Examples

example 1

[0028] Example 1, the specific implementation steps are:

[0029] (1) Add 20m 3 The above prepared nano-calcium carbonate cooked pulp and an appropriate amount of emulsifier, start the wheel-type mixer, stir, mix, and homogenize for 15 minutes; the emulsifier is sodium dodecylbenzenesulfonate, and the addition amount is 10 kg;

[0030] (2) Turn on the high-shear emulsification pump and carry out high-shear refinement to the slurry obtained in step (1) for 15 min; the rotating speed of the high-shear emulsification pump is 3500r / min;

[0031] (3) In terms of calcium carbonate mass, gradually add 2.5% composite modifier in the modification tank, close the emulsification pump after high-shear emulsification for 25 minutes, and continue to stir for 30 minutes; the composite modifier is oleic acid: sodium laurate: hard Aluminum stearate and lanthanum isostearate are compounded according to the weight ratio of 40:50:8:2;

[0032] (4) The slurry obtained in step (3) is subjected to...

example 2

[0033] Example 2, the specific implementation steps are:

[0034] (1) Add 20m 3 Prepare the nano-calcium carbonate cooked pulp and an appropriate amount of emulsifier above, start the wheel-type mixer, stir, mix, and homogenize for 15 minutes; 12 kg;

[0035] (2) Turn on the high-shear emulsification pump to carry out high-shear refinement for 15 min to the slurry obtained in step (1); the rotating speed of the high-shear emulsification pump is 4500r / min;

[0036] (3) In terms of calcium carbonate mass, gradually add 2.0% composite modifier in the modification tank, close the emulsification pump after high-shear emulsification for 25 minutes, and continue to stir for 30 minutes; the composite modifier is oleic acid: sodium stearate: Coconut oil and cerium isostearate are compounded according to the weight ratio of 40:50:8:2;

[0037] (4) The slurry obtained in step (3) is subjected to aging, thickening, pressure filtration, dynamic drying at 230° C., crushing and grading to...

example 3

[0038] Example 3, the specific implementation steps are:

[0039] (1) Add 20m 3 Prepare the nano-calcium carbonate cooked pulp and an appropriate amount of emulsifier, start the wheel mixer, stir, mix, and homogenize for 10 minutes; the emulsifier is made of fatty acid methyl ester polyether sodium sulfonate and ACUSOL830 in a mass ratio of 1:1. The amount added is 8 kg;

[0040] (2) Turn on the high-shear emulsification pump to carry out high-shear refinement to the slurry obtained in step (1) for 20 min; the rotating speed of the high-shear emulsification pump is 5000r / min;

[0041] (3) In terms of calcium carbonate mass, gradually add 3.0% composite modifier in the modification tank, close the emulsification pump after high-shear emulsification for 25 minutes, and continue stirring for 30 minutes; the composite modifier is isostearic acid: sodium oleate : Aluminum diisostearate, lanthanum isostearate, and cerium isostearate are compounded according to the weight ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com