A new method for the preparation of chitosan nanofiber-based composite filter membrane

A chitosan nano- and nano-fiber technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as difficulty in controlling the thickness of the functional cortex, hindering the large-scale use of nanofiber composite membranes, and seepage of casting liquid. , to achieve the effect of simple preparation method, easy large-scale production and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A new method for preparing chitosan nanofiber-based composite filter membrane, the specific steps are:

[0030] (1) polyacrylonitrile (PAN) (M w =120,000g / mol, Jinshan Petrochemical) 10g was dissolved in N,N-dimethylformamide (DMF) solvent 90g to obtain a transparent and uniform electrospinning solution;

[0031] (2) Chitosan (CS) (viscosity-average molecular weight 400cps, degree of deacetylation 85.5%, Jinan Haidebei Marine Biological Engineering Co., Ltd.) and polyethylene oxide (PEO) (Mv=1,000,000g / mol, Aldrich) according to The mass ratio of 9:1 was mixed and dissolved in 3wt% acetic acid aqueous solution to prepare a solution with a total mass fraction of 1wt%, and a certain amount of UV-crosslinkable monomer triethylene glycol dimethacrylate ( TEGDMA), the mass ratio of chitosan (CS) and triethylene glycol dimethacrylate (TEGDMA) is 1: 0.5, stirs evenly, obtains the transparent uniform electrostatic spray solution;

[0032] (3) Add the electrospinning solution ...

Embodiment 2-5

[0037] Adopt the preparation method similar to the chitosan nanofiber-based composite filter membrane in embodiment 1, difference is, in described step (2), chitosan (CS) and triethylene glycol dimethacrylic acid The mass ratios of the esters (TEGDMA) are 1:0, 1:1, 1:1.5, 1:2, respectively.

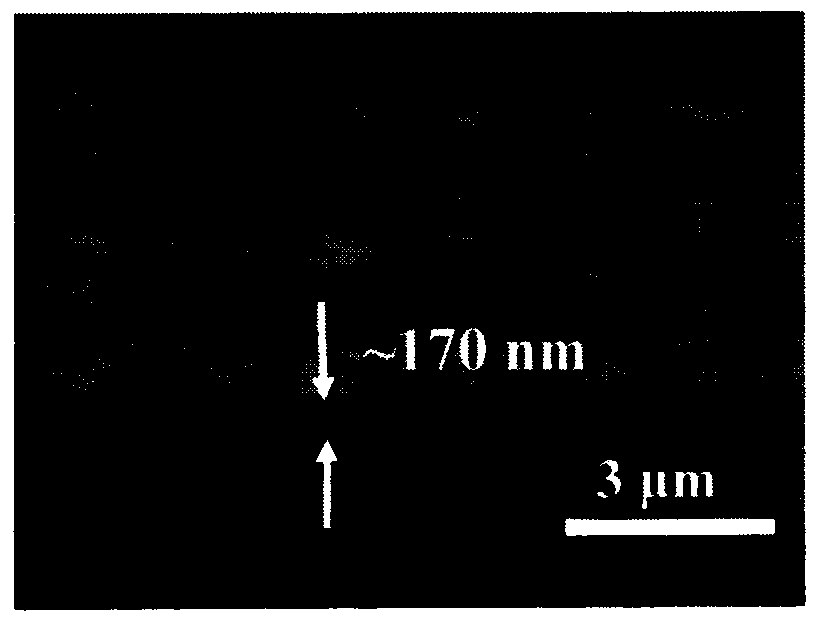

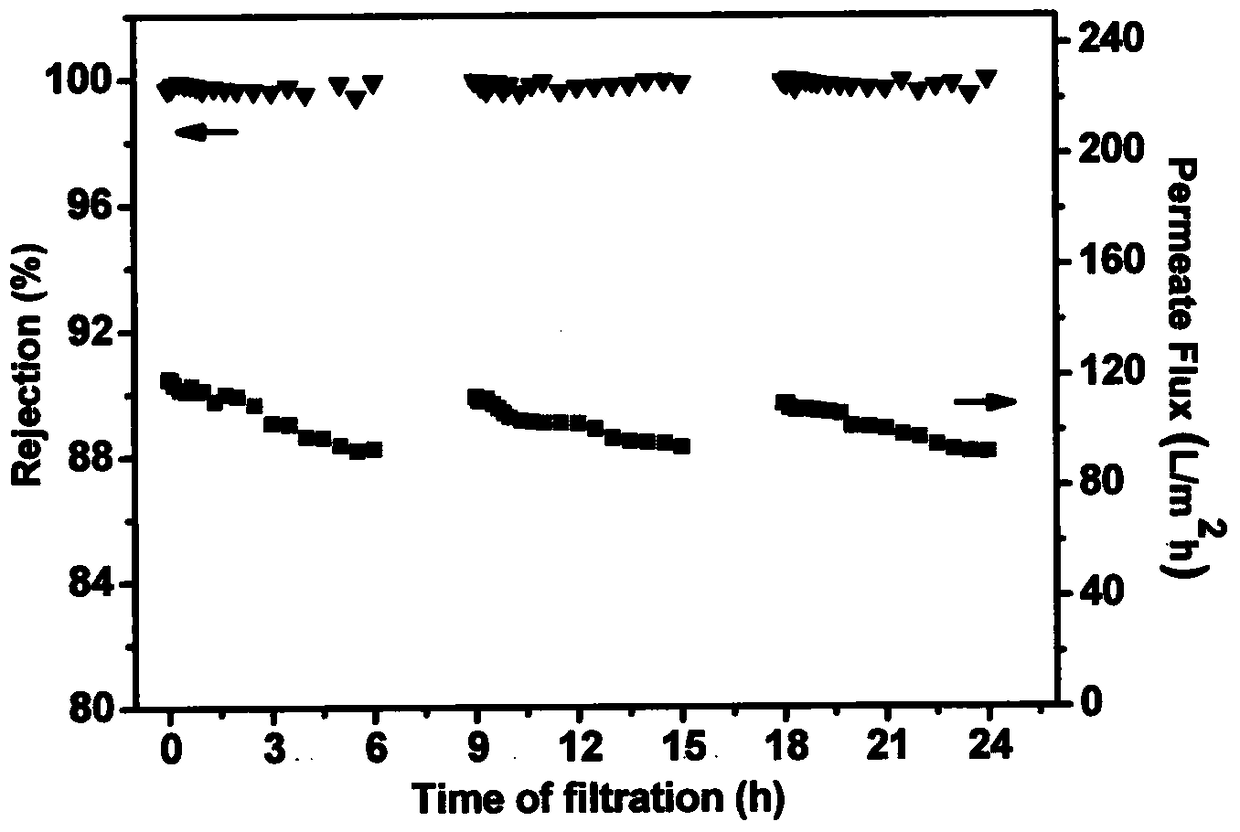

[0038] The CS-PEO-PEGDMA / PAN nanofiber base composite filter membrane prepared in embodiment 1-5 carries out dead-end filtration test to the acid dye direct red 80 of 100ppm: when chitosan (CS) and triethylene diethylene glycol When the mass ratio of alcohol dimethacrylate (TEGDMA) is 1: 0, 1: 0.5, 1: 1, 1: 1.5, and 1: 2, the prepared chitosan nanofiber-based composite filter membrane is used for 100ppm The acid dye Direct Red 80 was tested for dead-end filtration, the filtration operating pressure was 0.2MPa, and the corresponding permeation fluxes were 81.4, 117.5, 85.6, 77.2, 59.7L / m 2 h, the rejection rates were 93.2%, 99.9%, 99.8%, 99.5%, and 99.7%, respectively. It can be found th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com