Catalytic combustion active ingredient highly-dispersed catalyst and preparation method thereof

A technology of active components and catalytic combustion, which is applied in the direction of catalyst activation/preparation, combustion methods, physical/chemical process catalysts, etc. It can solve problems such as uneven dispersion, reduced dispersion, and increased particle size of noble metals to achieve high catalytic performance. The effect of high activity, simple preparation process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

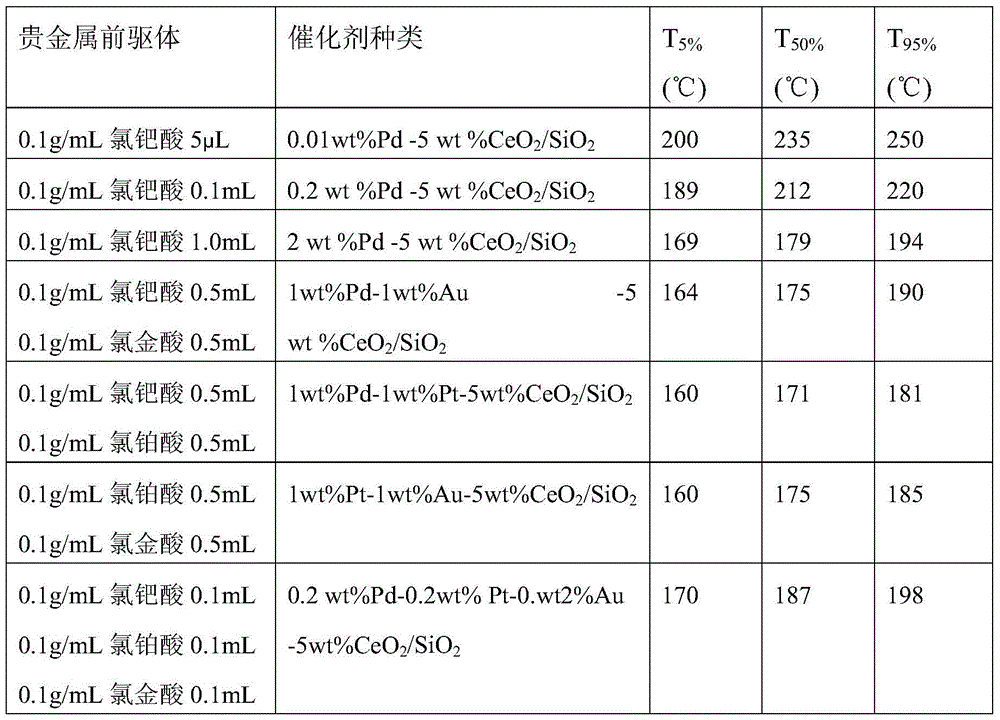

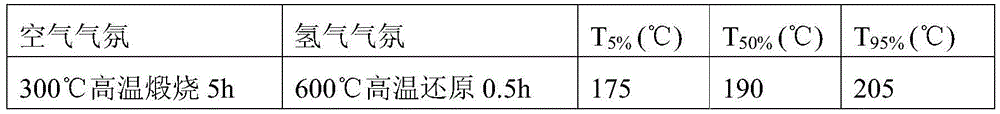

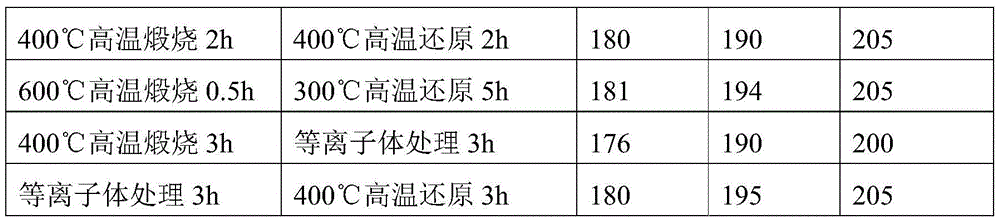

Embodiment 1

[0026] (1) Take 0.5mL of chloropalladium acid (or chloroauric acid or chloroplatinic acid) with a concentration of 0.1g / mL (the mass of Pd, Pt, and Au per milliliter), add deionized water to form a 10mL mixed solution;

[0027] (2) Add 0.2g octanoic acid in the above mixed solution, stir well;

[0028] (3) Add the above mixed solution to 5g SiO 2 Medium, equal volume immersion aging for 12 hours;

[0029] (4) After the above product is dried, low-temperature plasma treatment is carried out, and the plasma discharge mode is dielectric barrier discharge. first at 1000h -1 Low-temperature plasma treatment for 0.5 hours under the air atmosphere of space velocity, and then in 1000h -1 Low-temperature plasma treatment for 0.5 hours under a space velocity hydrogen atmosphere to obtain the product active component highly dispersed catalyst 1wt% Pd / SiO 2 (1wt%Au / SiO 2 , 1wt%Pt / SiO 2 ).

[0030] (5) Evaluate the catalytic combustion performance in a fixed bed reactor, the amount ...

Embodiment 2

[0035] (1) Take 0.5 mL of chloropalladic acid with a concentration of 0.1 g / mL (the mass of Pd per mL) and 0.63 g of cerium nitrate, add deionized water to form a 10 mL mixed solution;

[0036] (2) Add a certain amount of oily dispersant to the above mixed solution and stir evenly;

[0037] (3) Add the above mixed solution to 5g SiO 2 Medium, equal volume immersion aging for 6 hours;

[0038] (4) After the above product is dried, low-temperature plasma treatment is carried out, and the plasma discharge mode is dielectric barrier discharge. first at 1000h -1 Low-temperature plasma treatment for 2 hours under the air atmosphere of space velocity, and then in 1000h -1 Low-temperature plasma treatment under space velocity hydrogen atmosphere for 2 hours, the product active component highly dispersed catalyst 1wt%Pd-5wt%CeO 2 / SiO 2 .

[0039](5) Evaluate the catalytic combustion performance in a fixed bed reactor, the amount of catalyst is 0.1g, the concentration of VOCs sim...

Embodiment 3

[0044] (1) Take 0.5 mL of chloropalladic acid with a concentration of 0.1 g / mL (the mass of Pd per mL) and 0.63 g of cerium nitrate, add deionized water to form a 10 mL mixed solution;

[0045] (2) Add 0.2g lauric acid in the above mixed solution, stir evenly;

[0046] (3) Add the above mixed solution to 5g SiO 2 Medium, equal volume immersion aging for more than 6 hours;

[0047] (4) After the above product is dried, low-temperature plasma treatment is carried out, and the plasma discharge mode is dielectric barrier discharge. Firstly, low-temperature plasma treatment for 5 hours in an air atmosphere with a certain space velocity, and then a low-temperature plasma treatment for 5 hours in a hydrogen atmosphere with a certain space velocity, to obtain the product active component highly dispersed catalyst 1wt%Pd-5wt%CeO 2 / SiO 2 .

[0048] (5) Evaluate the catalytic combustion performance in a fixed bed reactor, the amount of catalyst is 0.1g, the concentration of VOCs sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com