A kind of preparation method of flower-like nano zinc oxide

A nano-zinc oxide and flower-shaped technology, applied in the field of nano-materials, can solve the problems of easy aggregation of particles, affecting the performance of final products, changes in shape and size, etc., and achieve the effects of easy recycling, low production cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the preparation method of flower-shaped nano-zinc oxide in the present embodiment is carried out according to the following steps:

[0019] Dissolve 10 g of rosin in 100 mL of absolute ethanol to make a 0.1 g / mL alcoholic solution of rosin.

[0020] 5 g of zinc acetate was dissolved in 30 mL of deionized water to obtain a zinc acetate solution.

[0021] Add 20mL of rosin alcohol solution to 90mL of 2mol / L sodium hydroxide solution prepared by sodium hydroxide and deionized water, stir and mix evenly, then slowly add zinc acetate solution dropwise under ice-water bath and stirring conditions, Control the drop rate to 1.5mL / min; then age at room temperature for 2 hours, pour into a high-pressure hydrothermal reactor lined with polytetrafluoroethylene, place in a 75°C oven for hydrothermal reaction for 12 hours, cool and crystallize naturally for 1 hour, and suction filter , the precipitate was washed 3 times with absolute ethanol and then 3 times...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that: 20 mL of rosin alcohol solution is added to 60 mL of sodium hydroxide solution with a concentration of 3 mol / L. Other steps and parameters are the same as in the first embodiment.

[0025] Using 0.1g of the flower-shaped nano-zinc oxide prepared by the method of this embodiment, catalytic degradation of 100mL concentration of 5mg / L methylene blue solution under the irradiation of an 18W ultraviolet lamp, continued stirring for 2.5h, and the degradation rate was nearly 100% (see Figure 5 ).

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment is different from Embodiment 1 in that: 20 mL of rosin alcohol solution is added to 45 mL of sodium hydroxide solution with a concentration of 4 mol / L. Other steps and parameters are the same as in the first embodiment.

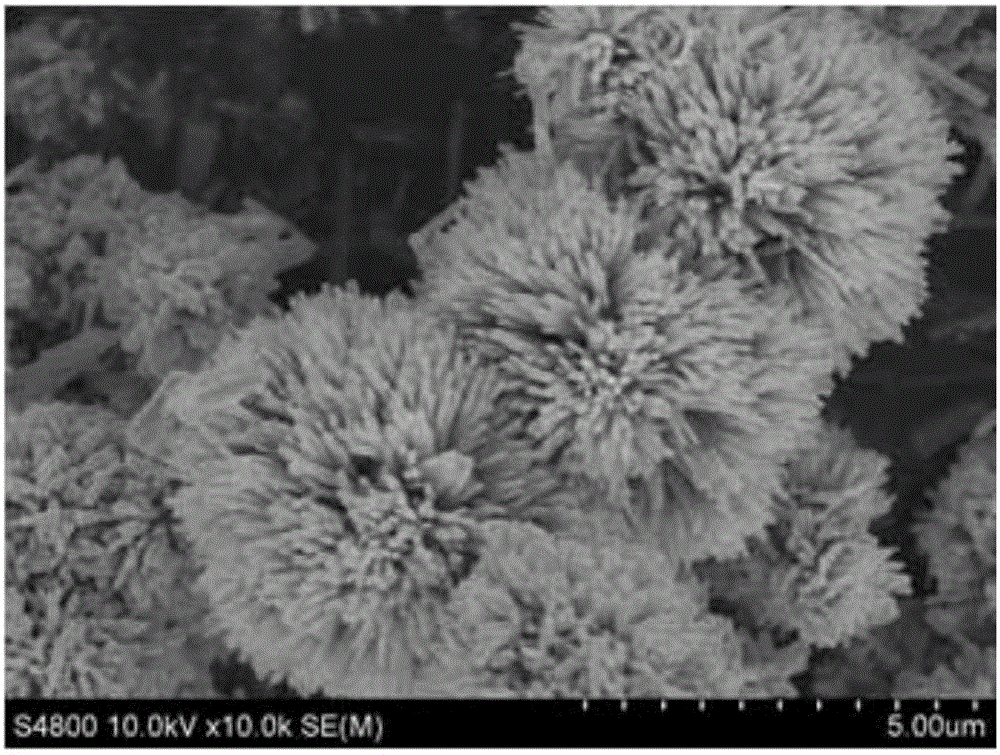

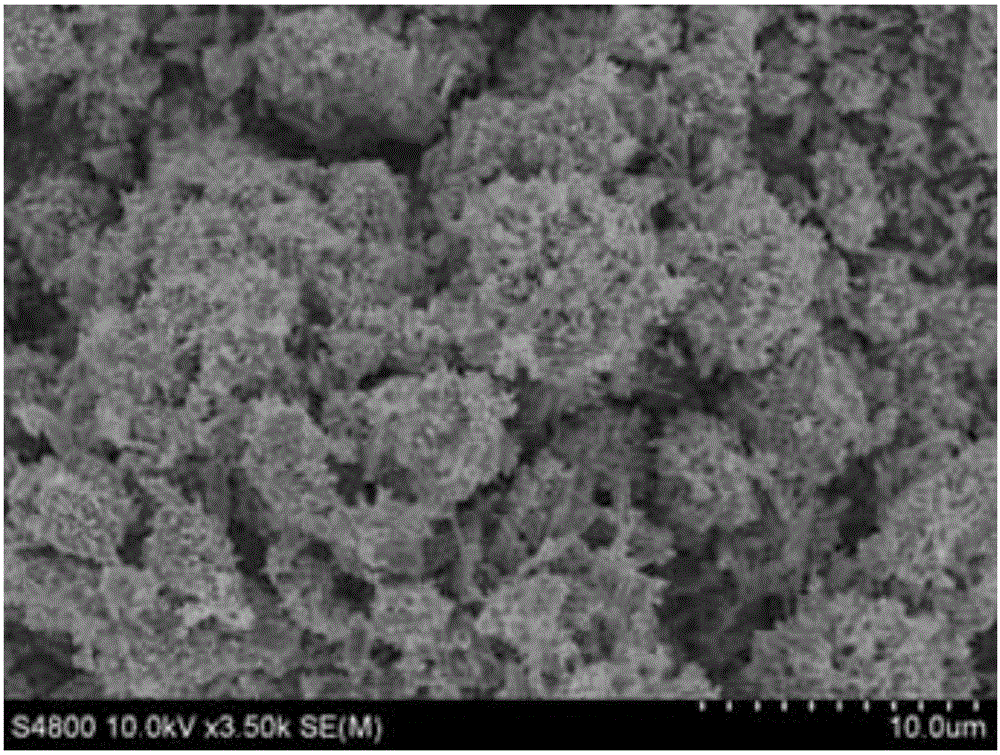

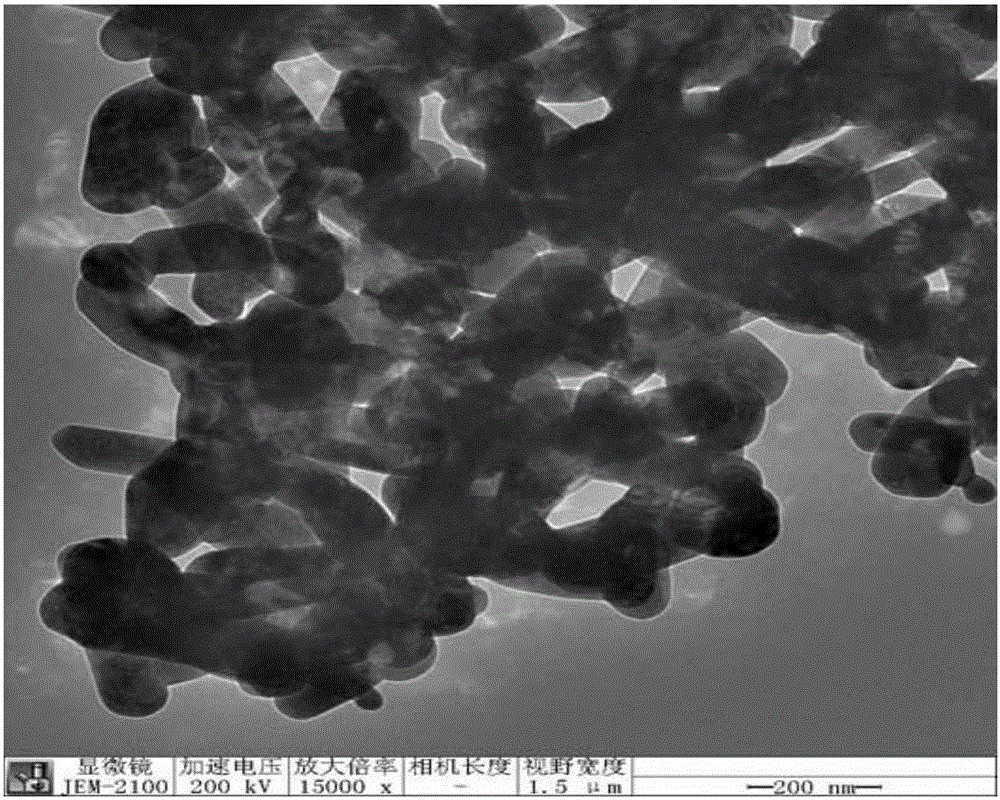

[0027] Depend on image 3 It can be seen that the nanorods formed by zinc oxide have a length of 400 nanometers and a width of about 90 nanometers.

[0028] Depend on Figure 4 It can be seen that the calcined product is pure zinc oxide, does not contain other impurities, and has high crystallinity.

[0029] Using 0.1g of the flower-shaped nano-zinc oxide prepared by the method of this embodiment, catalytic degradation of 100mL concentration of 5mg / L methylene blue solution under the irradiation of an 18W ultraviolet lamp, continued stirring for 2.5h, and the degradation rate was nearly 100% (see Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com