A treatment system for waste water containing inorganic ammonium salts and a resource treatment method thereof

An inorganic ammonium salt and treatment system technology, which is applied in textile industry wastewater treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of secondary pollution of the surrounding environment, large consumption of iron carbon and hydrogen peroxide, and high operating costs, achieving Good economic and environmental benefits, reduced loss of ammonia nitrogen resources, simple and effective treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

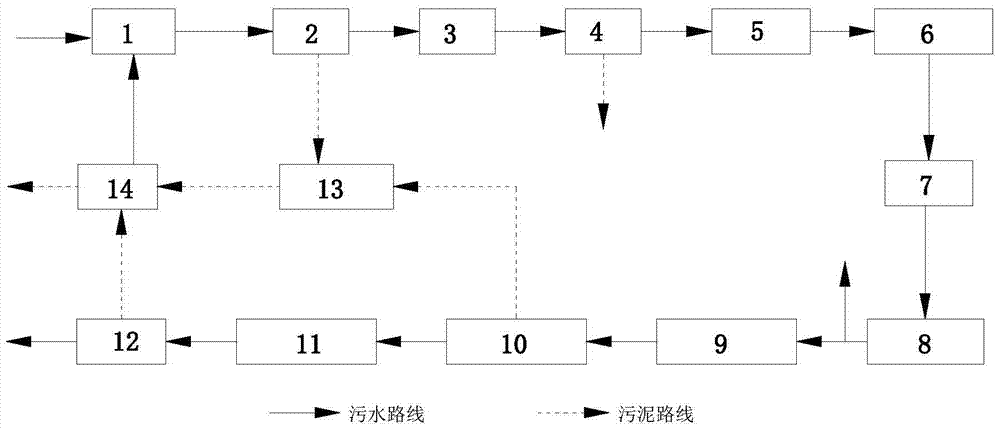

[0041] A kind of treatment system of waste water containing inorganic ammonium salt of the present invention, the treatment system of described waste water containing inorganic ammonium salt comprises grille 1, buffer tank 2, regulating tank 3, filter 4, buffer tank 5, MVR evaporator 6, Regulating tank 7, ammonia nitrogen removal system 8, Fenton oxidation tank 9, flocculation sedimentation tank 10, intermediate regulating tank 11, SBR tank 12, sludge thickening tank 13, filter press 14;

[0042] The grille 1, the regulating tank 3, the buffer tank 5, the MVR evaporator 6, the regulating tank 7, the ammonia nitrogen removal system 8, the Fenton oxidation tank 9 and the intermediate regulating tank 11 are all provided with inlets and outlets, and the buffer tank 2 An inlet, a first outlet and a second outlet are provided on the sludge thickening tank 13, a first inlet, a second inlet, a third inlet, a fourth inlet and an outlet are provided on the sludge thickening tank 13, and ...

Embodiment 2

[0059] The difference between embodiment 2 and embodiment 1 is: the resource treatment method of the treatment system of the waste water containing inorganic ammonium salt according to the present invention, comprises the following steps:

[0060] In step (3), the supernatant of the buffer pool 2 overflows to the regulating kettle 3, supplemented by stirring to adjust the pH value of the wastewater, a pH control system and a stirring system are provided, and the pH value of the wastewater is adjusted to 6; with 98% sulfuric acid The added quality is 13kg per ton of waste water, and the residence time of the waste water in the regulating kettle 3 is 0.8h. The anti-coking agent is thiourea dioxide, and the added quality of thiourea dioxide is 0.25% of the waste water quality; the adsorbent is granular activated carbon, granular The quality of activated carbon is 0.1% of the waste water quality;

[0061] In step (6), the pH value of the waste water in the adjustment tank 7 is adj...

Embodiment 3

[0067] The difference between embodiment 3 and embodiment 1 is: the resource treatment method of the treatment system of wastewater containing inorganic ammonium salt according to the present invention, comprises the following steps:

[0068] In step (3), the supernatant of the buffer pool 2 overflows to the regulating kettle 3, supplemented by stirring to adjust the pH value of the waste water, a pH control system and a stirring system are provided, and the pH value of the waste water is adjusted to 5.5; The added quality is 24kg per ton of waste water, and the residence time of the waste water in the regulating kettle 3 is 1h. The anti-coking agent is dimethyl disulfide, and the added quality of dimethyl disulfide is 0.4% of the waste water quality; the adsorbent It is granular activated carbon, and the mass of granular activated carbon is 0.2% of the waste water mass;

[0069] In step (6), the pH of the influent in the adjustment tank 7 is greater than 7, and the ammonia ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com