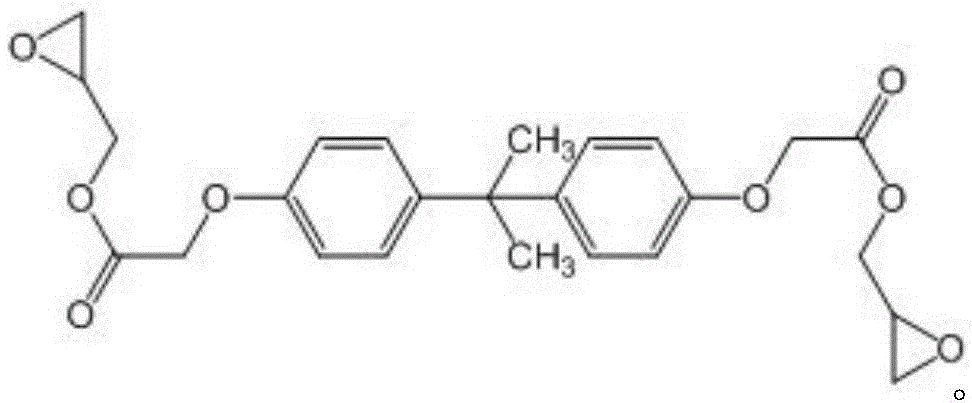

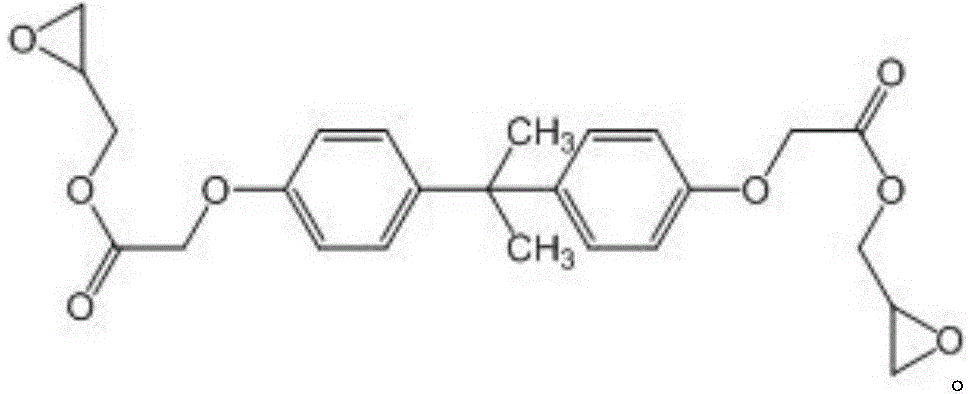

Bisphenol-A glycidyl-ester type epoxy resin and preparing method thereof

A glycidyl ester, epoxy resin technology, applied in the chemical industry, can solve the problems of poor toughness and heat resistance, and achieve the effects of improving heat resistance, easy use, improving toughness and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

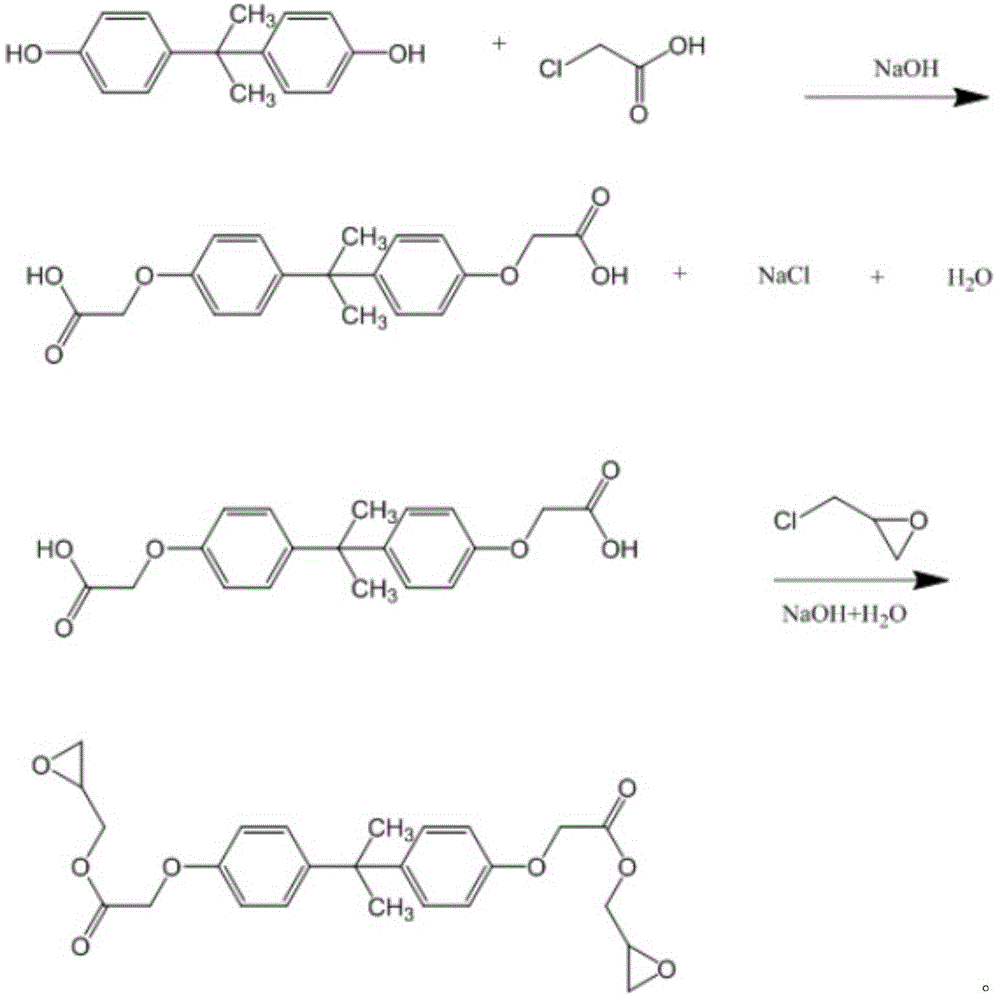

Method used

Image

Examples

Embodiment 1

[0017] Add 228 grams of bisphenol A and 120 grams of sodium hydroxide solid in the autoclave, 2000 mL of n-butanol as a solvent, stir and heat up to 60 ° C, then slowly add 95 grams of chloroacetic acid dropwise within 30 minutes, after the addition is completed, React at 60°C for 4 hours, add hydrochloric acid to acidify to pH = 7, then wash with 1000 g of water and 5000 mL of dichloroethane, let stand to separate layers, and divide to obtain the organic phase. Vacuumize at 80°C for 4 hours to obtain bisphenol-based monobasic acid, then stir and mix the cardanol monobasic acid with 500 grams of epichlorohydrin and cool to 60°C, slowly add 160 grams of 50% aqueous sodium hydroxide solution dropwise, 100 React at ℃ for 3 hours, wash and extract with water, remove water and excess reagents, and obtain bisphenol glycidyl ester type epoxy resin. Epoxy value 0.37, viscosity 20000CPS and MD650 board, mold thickness 50 microns, toughness 1mm, adhesion level 1, hardness HB, heat resis...

Embodiment 2

[0019] Add 228 grams of bisphenol A and 120 grams of solid sodium hydroxide into the autoclave, 2000 mL of ethanol as the solvent, stir and heat up to 60°C, then slowly add 114 grams of chloroacetic acid dropwise within 30 minutes, and the dropwise temperature is 80°C React for 4 hours, add hydrochloric acid to acidify to pH = 7, then add 1000 g of water, wash with 5000 mL of dichloroethane, let stand to separate layers, and split to get the organic phase. Vacuumize at 80°C for 4 hours to obtain bisphenol-based monobasic acid, then stir and mix the bisphenol-based monobasic acid with 600 grams of epichlorohydrin and cool to 60°C, slowly add 180 grams of 50% aqueous sodium hydroxide solution dropwise, 100 React at ℃ for 3 hours, wash and extract with water, remove water and excess reagents, and obtain bisphenol glycidyl ester type epoxy resin. Epoxy value 0.35 Viscosity: 26000CPS, and MD650 plate, mold thickness 50 microns, toughness 1mm, adhesion level 1, hardness HB, heat res...

Embodiment 3

[0021] Add 228 grams of bisphenol A and 80 grams of sodium hydroxide solid in the autoclave, 2000 mL of propanol as a solvent, stir and heat up to 60 ° C, then slowly add 95 grams of chloroacetic acid dropwise within 30 minutes, and drop it at 60 React at ℃ for 4 hours, add hydrochloric acid to acidify to pH = 7, then add 1000 g of water, wash with 5000 mL of dichloroethane, let stand to separate the layers, and split to get the organic phase. Vacuumize at 100°C for 4 hours to obtain bisphenol-based monobasic acid, then stir and mix the bisphenol-based monobasic acid with 1000 grams of epichlorohydrin and cool down to 60°C, slowly add 250 grams of 50% aqueous sodium hydroxide solution dropwise, 100 React at ℃ for 3 hours, wash and extract with water, remove water and excess reagents, and obtain bisphenol glycidyl ester type epoxy resin. Epoxy value 0.40, viscosity: 15500CPS and MD650 board, mold thickness 50 microns, toughness 1mm, adhesion level 1, hardness HB, heat resistanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com