Multipolymer resin, multipolymer compound base film and preparation method of multipolymer compound base film

A multi-copolymer, composite base film technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as easy film breakage, environmental pollution, and difficulty in film stretching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

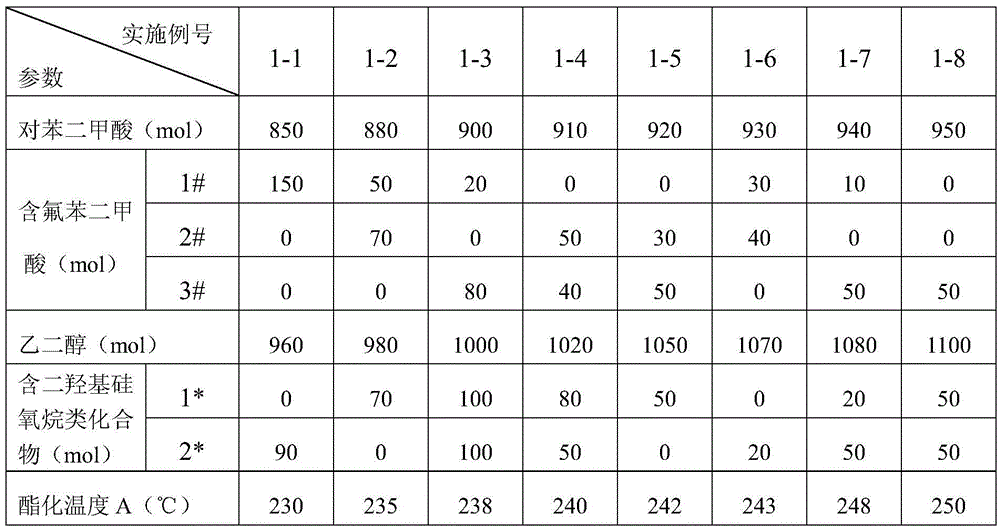

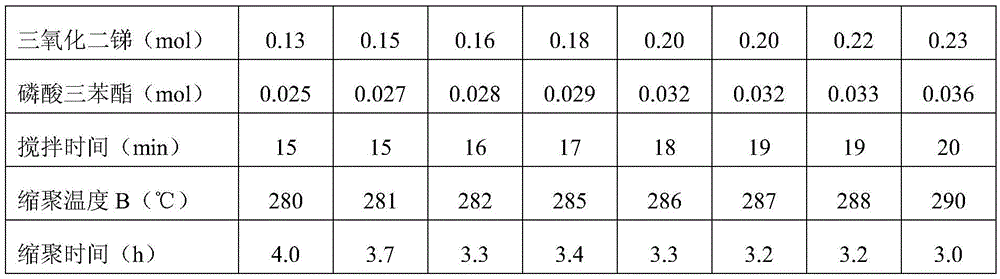

[0042] Preparation of the first part multi-component copolymer resin

[0043] Basic process and raw materials:

[0044] First, 1000mol of dibasic formic acid is made into terephthalic acid by molar ratio: fluorine-containing phthalic acid = 850-950: 50-150 ingredients; Siloxane compound = 950~1100: 100~250 ingredients, add together into the reactor, the initial pressure in the reactor is 0.2MPa, when the temperature in the reactor rises to 230℃~250℃, collect the distilled water from esterification, pass Calculate the esterification rate by water output, when the esterification rate reaches 97%, start to (slowly) release the pressure, add catalyst 0.13mol~0.23mol antimony trioxide, stabilizer 0.025mol~0.036mol triphenyl phosphate, stir for 15min~ After 20 minutes, start to (slowly) vacuumize until the residual pressure in the reactor is less than 60Pa, and heat up to 280°C to 290°C for polycondensation. The polycondensation time is 3h to 4h, and the N 2 Discharging, that is, ...

Embodiment 3

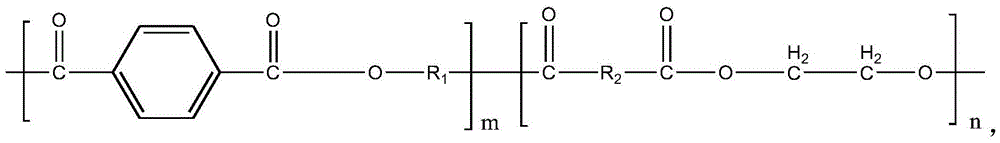

[0066] A kind of multiple copolymer resin, the molecular structure general formula of this multiple copolymer resin is:

[0067]

[0068] In the formula: Wherein: m is 5-10, n is 10-15, X is 5-10, Y is 3-5, m, n, X and Y are all integers;

[0069] The intrinsic viscosity of the multi-component copolymer resin is 0.60dl / g-0.68dl / g, the melting range is 235°C-252°C, and the molecular weight is 6000-28000;

[0070]The preparation method of the multi-component copolymer resin is as follows: add 1000mol of dibasic acid and 1050mol to 1200mol of dihydroxy compound into the reactor, the initial pressure in the reactor is 0.2MPa, when the temperature in the reactor rises to 230°C-250°C, Collect the distilled water from esterification, and calculate the esterification rate by the water output. When the esterification rate reaches 97%, start to (slowly) release the pressure, and add (catalyst) 0.13mol~0.23mol of antimony trioxide, (stabilizer) 0.025 mol~0.036mol triphenyl phosph...

Embodiment 4

[0076] A multi-component copolymer composite base film, which is composed of multi-component copolymer film of A layer (abbreviation: A layer) and B layer PET film (abbreviation: B layer), and its layered structure is A / B two layers, thickness The mass ratio of multi-layer copolymer film of layer A to PET film of layer B is 10:100; the hydrolysis resistance of the multi-layer copolymer composite base film is: when the elongation at break is attenuated to 10% by cooking at 121°C , cooking time up to 60h ~ 96h; at 38 ° C, 90% RH (RH is RelativeHumidity, that is, relative humidity) test environment, the water vapor transmission rate is 0.8g / m 2 ·24h~1.3g / m 2 24h range;

[0077] The preparation method of the multi-component copolymer composite base film is: the multi-component copolymer resin for the multi-component copolymer film of 10 mass parts A layer and the PET resin for the PET film of 100 mass parts B layer are passed through the extruder A respectively. After the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Melting range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com