Waterproof soybean meal adhesive and preparation method thereof

A technology of gluten and adhesive is applied in the field of adhesives based on soybean protein, which can solve problems such as hindering the large-scale popularization and application of wood-based panels, and achieve the effects of saving production costs, increasing added value and lowering prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1 modified nanocellulose

[0037] The proportion by weight of the nanocellulose modified raw material is: dispersion medium: 90 parts, nanocellulose: 10 parts, surface modifier: 20 parts. The modification process is carried out according to the following steps:

[0038] 1) Disperse the surface modifier γ-glycidyl etheroxypropyl trimethoxysilane in ethanol / water mixed solvent (90 / 10, V / V), 2) adjust the pH value to 4.0 with acetic acid; 3) add nano Cellulose; 4) reflux reaction for 4 hours; 5) filter, dry, and set aside.

[0039] The modified nanocellulose prepared in this example was used for subsequent experiments.

Embodiment 2

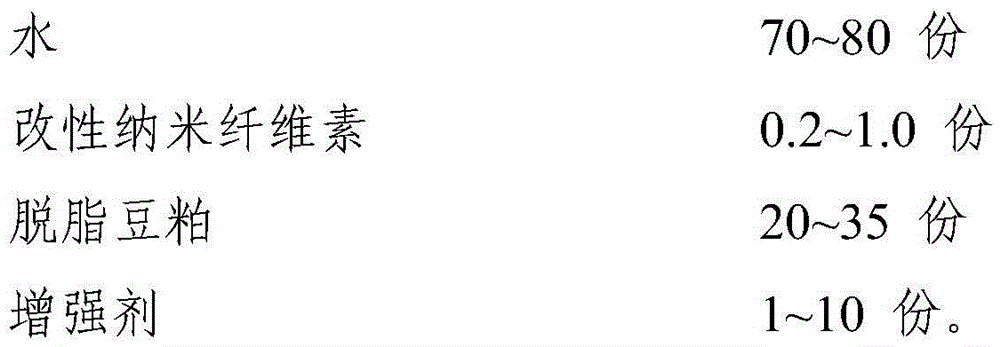

[0041] 1) Prepare materials according to the following weight ratio:

[0042]

[0043] 2) In a reaction kettle equipped with a stirrer, a thermometer and a condensing device (the reaction is carried out at normal temperature), add all the tap water and soybean meal and stir evenly.

[0044] 3) Add glycerol triglycidyl ether and modified nanocellulose and stir evenly to prepare uniform soybean protein mucilage.

[0045] 4) The above-mentioned mucus is processed by a homogenizer after passing through a colloid mill, and the homogenization pressure is 25MPa.

[0046] Three batches of parallel samples were prepared by the same process, and the performance and quality indicators of the adhesive obtained are shown in Table 1.

[0047] Example 2

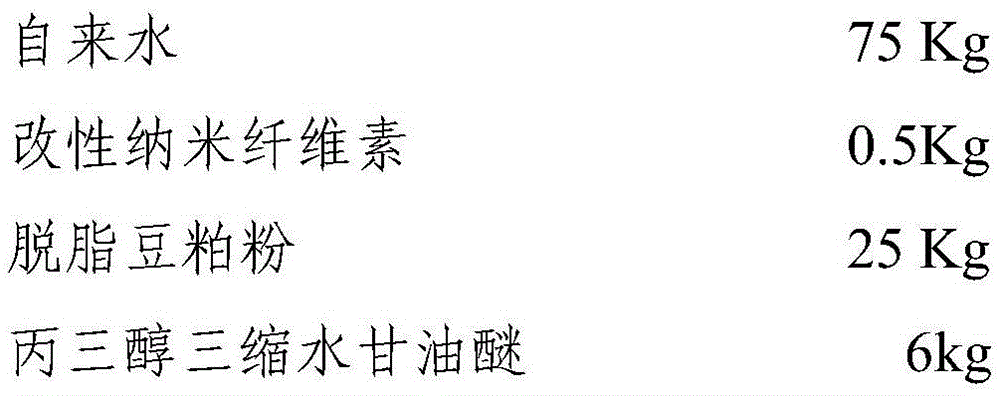

[0048] 1) Prepare materials according to the following weight ratio:

[0049]

[0050] 2) In a reaction kettle equipped with a stirrer, a thermometer and a condensing device, add all the tap water and soybean meal powder, and stir ...

Embodiment 3

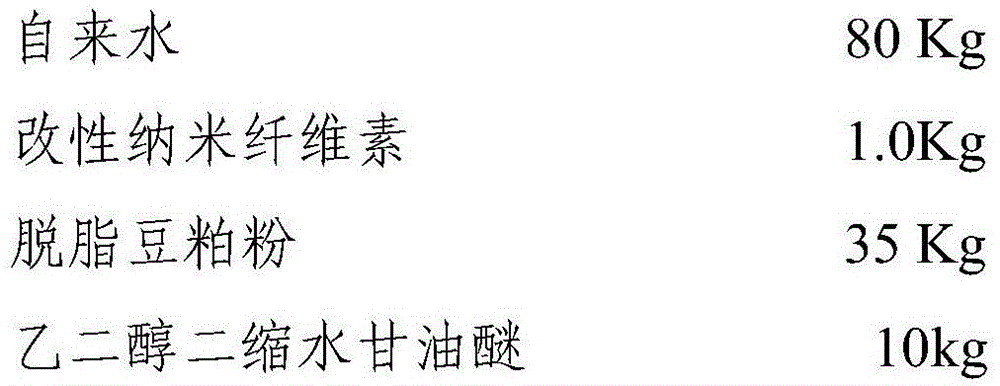

[0055] 1) Prepare materials according to the following weight ratio:

[0056]

[0057] 2) In a reaction kettle equipped with a stirrer, a thermometer and a condensing device, add all the tap water and soybean meal powder, and stir evenly.

[0058] 3) adding ethylene glycol diglycidyl ether and modified nanocellulose and stirring evenly to prepare uniform soybean protein mucilage.

[0059] 4) The above-mentioned mucus is processed by a homogenizer after passing through a colloid mill, and the homogenization pressure is 25MPa.

[0060] Among them, the quality index of soybean protein adhesive is shown in Table 1.

[0061] Table 1 Performance Index of Soybean Protein Adhesive

[0062]

[0063] The prepared adhesive sample has a storage period of 3-5 days (after 3-5 days, there will be local mildew or odor, but the bonding performance will not be affected).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com