Preparation method of organic nanocrystals

A technology of nanocrystals and organic crystals, which is applied in the field of preparation of organic nanocrystals, can solve the problems of easy aggregation of particles, difficulty in controlling the size, shape and uniformity, and difficult aggregation, so as to achieve difficult aggregation, reduce solvent embedding and particle Aggregation, lattice integrity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

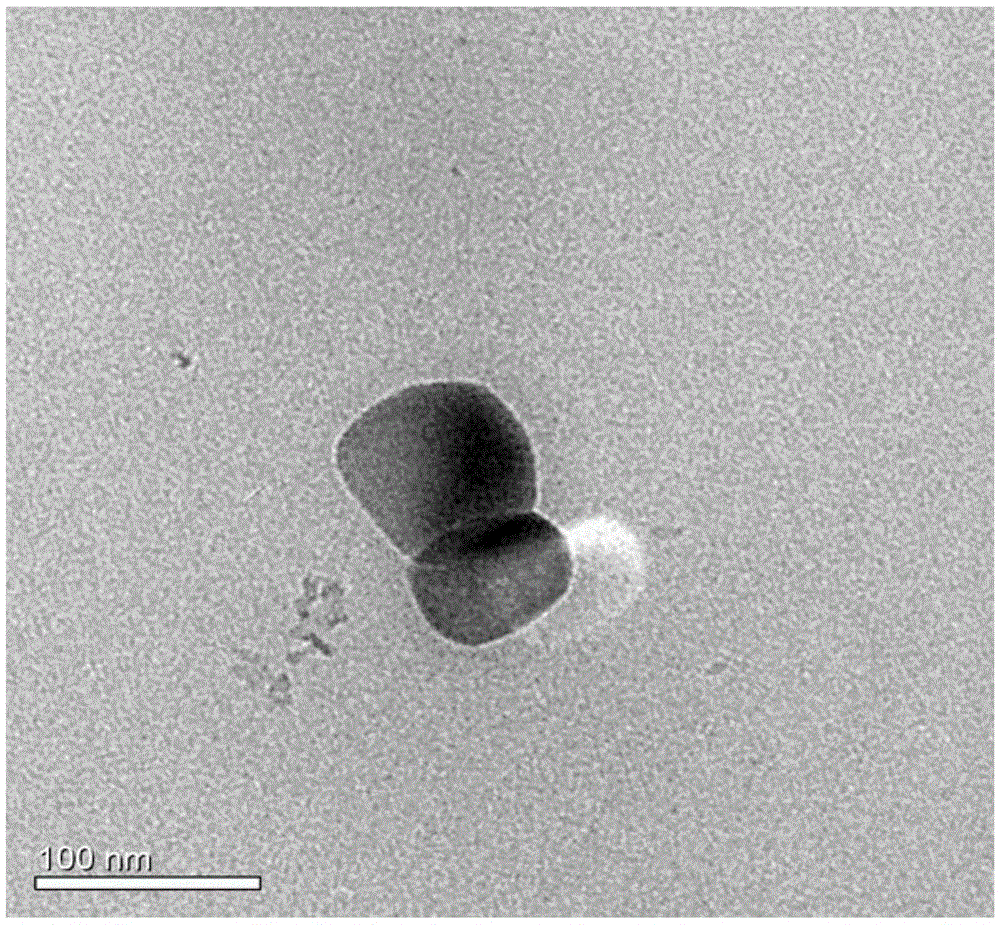

[0033] Method for preparing organic nanocrystals

[0034] Take a certain amount of organic crystal raw material and modifier, dissolve the organic crystal raw material and modifier in an organic solvent, and stir evenly. Then the organic crystal-organic solvent-modifier is added dropwise in a certain amount of organic solvent for further dilution. The mixed solution is added dropwise on the heating substrate for evaporation, and the temperature of the heating substrate is close to or higher than the boiling point of the selected organic solvent.

Embodiment 2

[0036] Method for preparing organic nanocrystals

[0037] Take a certain amount of organic crystal raw material and modifier, dissolve the organic crystal raw material and modifier respectively in the same organic solvent, and stir separately. Then the two are mixed, further stirred evenly, and then the mixed liquid is added dropwise on the heating substrate for evaporation, and the temperature of the heating substrate is close to or higher than the boiling point of the selected organic solvent.

Embodiment 3

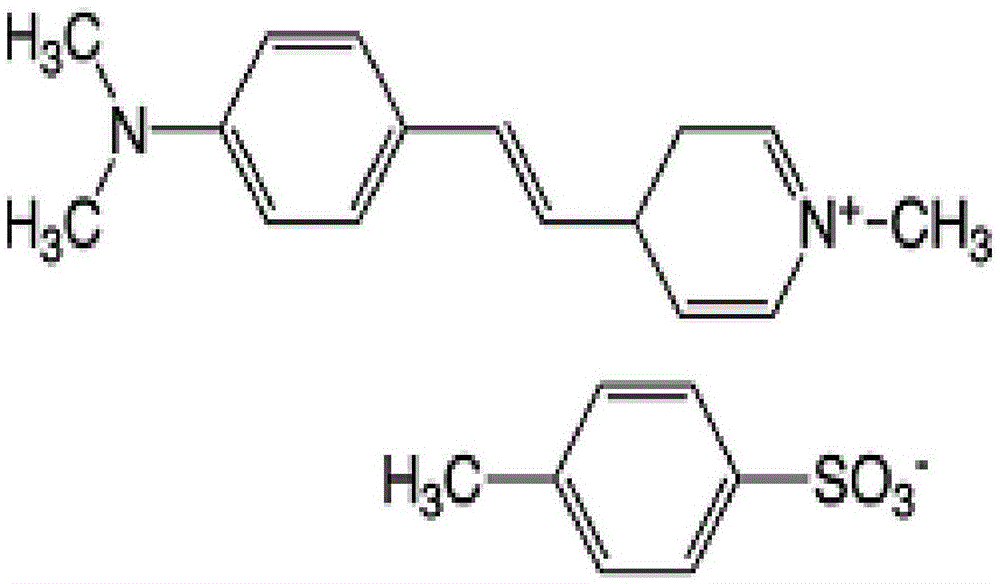

[0039] Preparation of DAST nanocrystals

[0040] Take 0.01g of DAST and 0.02g of cetyltrimethylammonium bromide (CTAB) into 5ml of anhydrous methanol, and stir at 60°C and 500rad / min for 1.5 hours. Take 0.1ml of DAST-methanol-CTAB at room temperature, add it to 10ml of anhydrous methanol, stir at 1200rad / min for 30s, take 0.05ml of the stirred DAST-methanol-CTAB solution, and evaporate it under the heating substrate at 80 degrees Celsius.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com