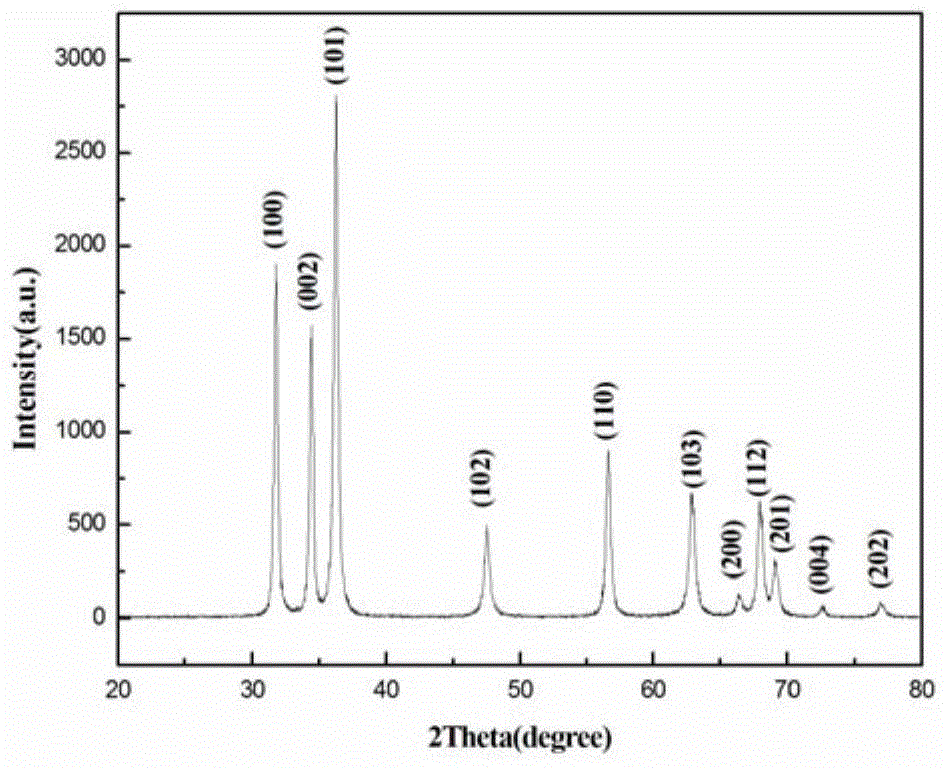

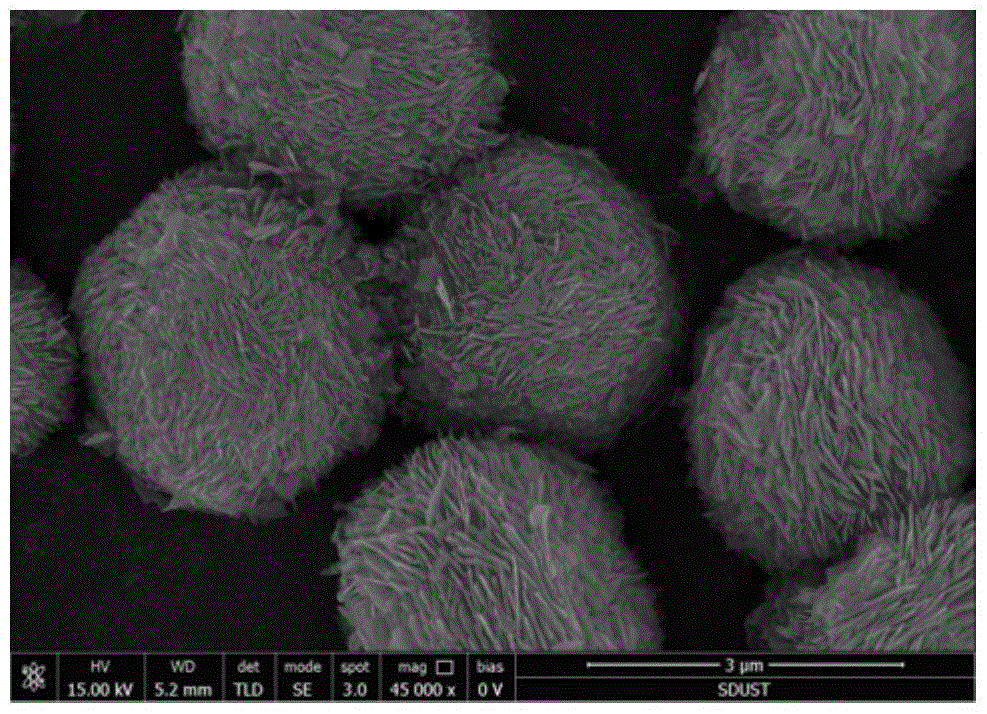

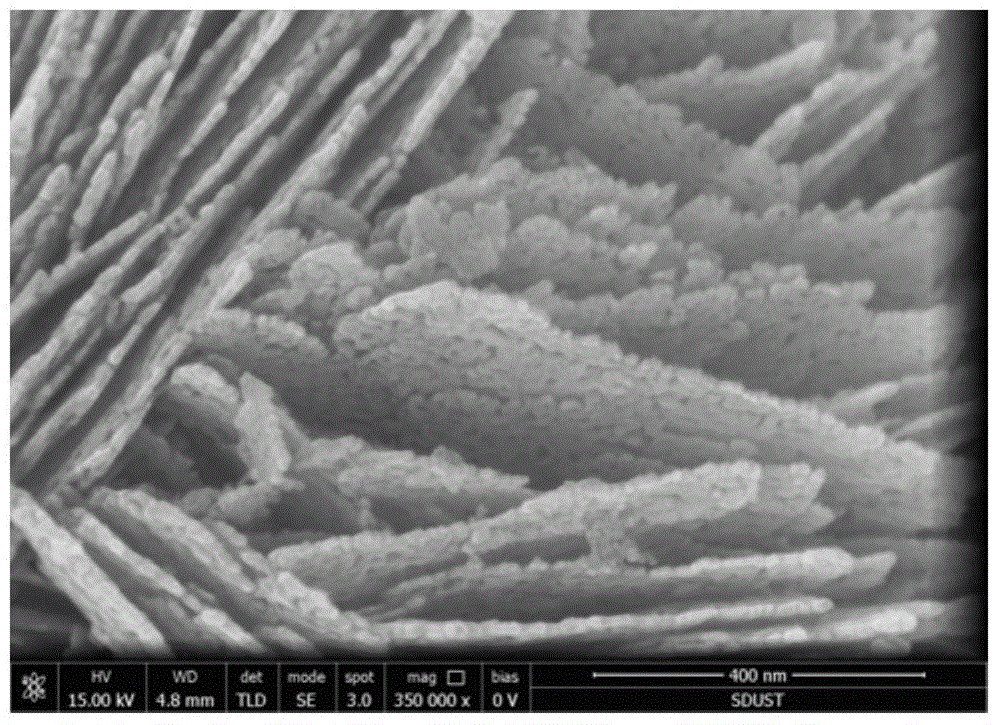

A kind of preparation method of porous zinc oxide with three-dimensional structure

A porous zinc oxide, three-dimensional technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve environmental pollution and other problems, achieve simple and easy-to-control process, high specific surface area Large, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation method of the porous zinc oxide with three-dimensional structure is characterized in that it comprises the following steps:

[0054] In the first step, according to the mass ratio of 1-3:1:1:2.5-10:0.9-2.8, respectively weigh 0.21g of zinc acetate, 0.2g of potassium sulfate, 0.2g of glycine, 0.5g of polyvinylpyrrolidone and 0.195g of ammonium carbonate ,spare;

[0055] In the second step, the zinc acetate, potassium sulfate, glycine and polyvinylpyrrolidone were mixed, and 20ml of deionized water was added as a solvent, and stirred to form solution A;

[0056] The third step is to add deionized water to the ammonium carbonate taken to prepare an ammonium carbonate solution with a mass percentage concentration of 1%; and add the above-mentioned ammonium carbonate solution to the above-mentioned solution A, stir evenly, and obtain a mixed solution B;

[0057] The fourth step is to pour the obtained mixed solution B into a polytetrafluoroethylene-lined sta...

Embodiment 2

[0070] The preparation method of the porous zinc oxide with three-dimensional structure is characterized in that it comprises the following steps:

[0071] In the first step, according to the mass ratio of 1-3: 1: 1: 2.5-10: 0.9-2.8, respectively weigh 0.63g of zinc acetate, 0.2g of potassium sulfate, 0.2g of glycine, 2g of polyvinylpyrrolidone and 0.585g of ammonium carbonate, spare;

[0072] In the second step, the zinc acetate, potassium sulfate, glycine and polyvinylpyrrolidone were mixed, and 20ml of deionized water was added as a solvent, and stirred to form solution A;

[0073] The third step is to add deionized water to the ammonium carbonate taken to prepare an ammonium carbonate solution with a mass percentage concentration of 3%; and add the above-mentioned ammonium carbonate solution to the above-mentioned solution A, stir evenly, and obtain a mixed solution B;

[0074] The fourth step is to pour the obtained mixed solution B into a polytetrafluoroethylene-lined s...

Embodiment 3

[0083] The preparation method of the porous zinc oxide with three-dimensional structure is characterized in that it comprises the following steps:

[0084] In the first step, according to the mass ratio of 1-3: 1: 1: 2.5-10: 0.9-2.8, respectively weigh 0.42g of zinc acetate, 0.2g of potassium sulfate, 0.2g of glycine, 1g of polyvinylpyrrolidone and 0.39g of ammonium carbonate, spare;

[0085] In the second step, the obtained zinc acetate, potassium sulfate, glycine and polyvinylpyrrolidone are mixed, and 40ml of deionized water is added as a solvent, stirred to form solution A;

[0086] The third step is to add deionized water to the ammonium carbonate taken to prepare an ammonium carbonate solution with a mass percentage concentration of 2%; and add the above-mentioned ammonium carbonate solution to the above-mentioned solution A, stir evenly, and obtain a mixed solution B;

[0087] The fourth step is to pour the obtained mixed solution B into a polytetrafluoroethylene-lined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com