Low-cost treatment method and device for petrochemical waste lye

A treatment method and technology of waste lye, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of hindering the formation of electric field, increasing power consumption, and losing catalytic effect of catalyst particles and other problems, to achieve the effect of significant economic benefits and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A refinery waste lye: water volume 50m 3 / h,S 2- It is 15000mg / L, the conductivity is 30000μs / cm, and the COD is 5500mg / L.

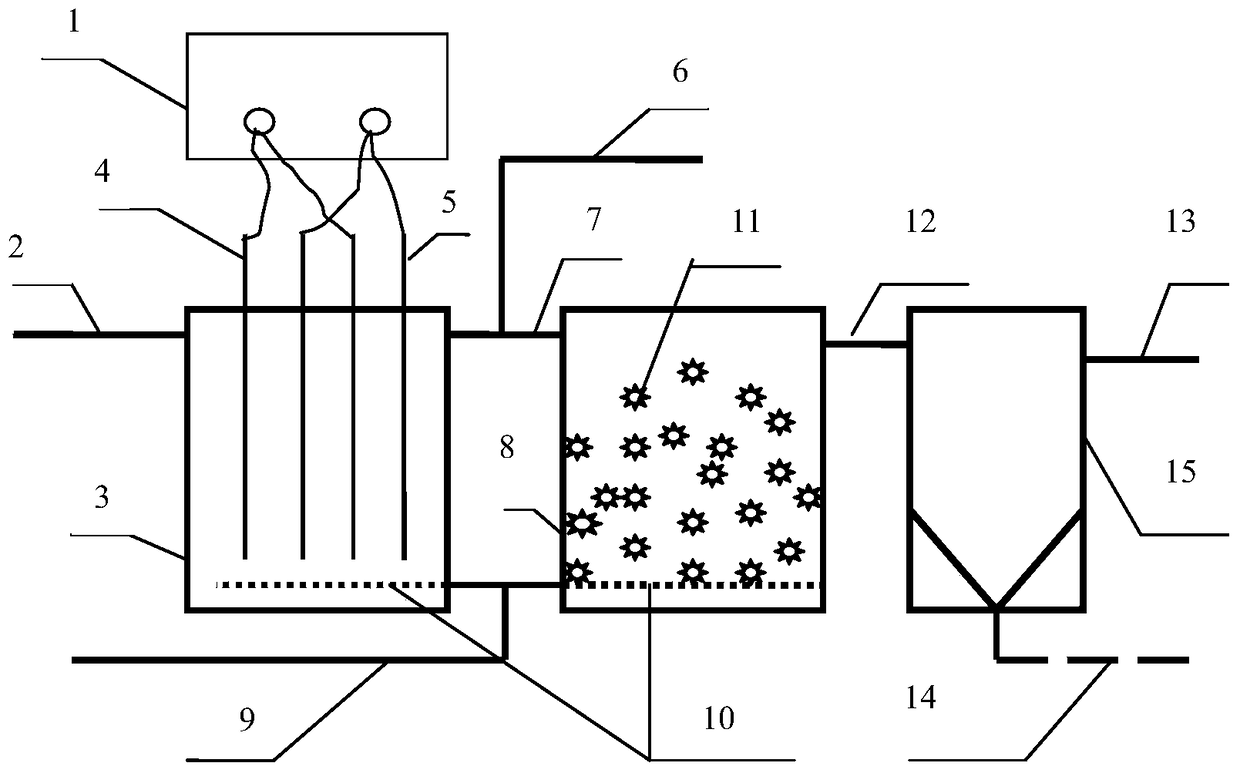

[0028] Devices for low-cost treatment of petrochemical waste lye: such as figure 1 As shown, it includes an electrolytic catalytic oxidation reactor, a biochemical reactor 8, and a sedimentation tank 15 connected in sequence. The electrolytic catalytic oxidation reactor includes a DC power supply 1, an electrolytic cell 3, and the front end of the electrolytic cell 3 is provided with a water inlet pipe 2, and the rear end is passed through electrolysis. The connecting pipe 7 between the tank and the biochemical reactor is communicated with the biochemical reactor 8, and the rear end of the biochemical reactor 8 is communicated with the sedimentation tank 13 through the connecting pipe 12 between the biochemical reactor and the sedimentation tank. The connecting pipe 7 is provided with a low-salt sewage water distribution pipe 6, the rear end of ...

Embodiment 2

[0032] The device of the low-cost treatment method for petrochemical waste lye used in Example 2 is the same as that in Example 1.

[0033] Waste lye from an olefin factory: water volume 2m 3 / h,S 2- It is 70000mg / L, the conductivity is 140000μs / cm, and the COD is 81600mg / L.

[0034] Treatment process: the waste lye to be treated enters the electrolytic cell 3 through the water inlet pipe 2, turns on the DC power supply 1, and adjusts the output current so that the current density between the alkali-resistant anode 4 and the stainless steel cathode 5 is 100mA / cm 2 , the distance between the alkali-resistant anode 4 and the stainless steel cathode 5 is 3 cm, and the electrolytic oxidation reaction time is 180 minutes. 3 / h of low-salt sewage (conductivity 2100μs / cm, COD is 545mg / L) also enters the biochemical reactor 8 through the connecting pipe 7 between the electrolytic cell 3 and the biochemical reactor 8 through the low-salt sewage water distribution pipe 6 to keep the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com