Sub-permeable membrane wastewater treatment system and process

A wastewater treatment system and osmotic membrane technology, applied in osmosis/dialysis water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. Achieve the effect of increasing residence time, simplifying process flow, and eliminating foul odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

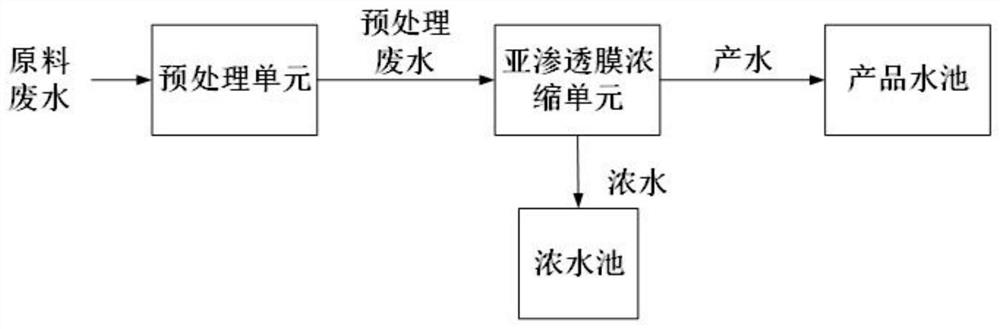

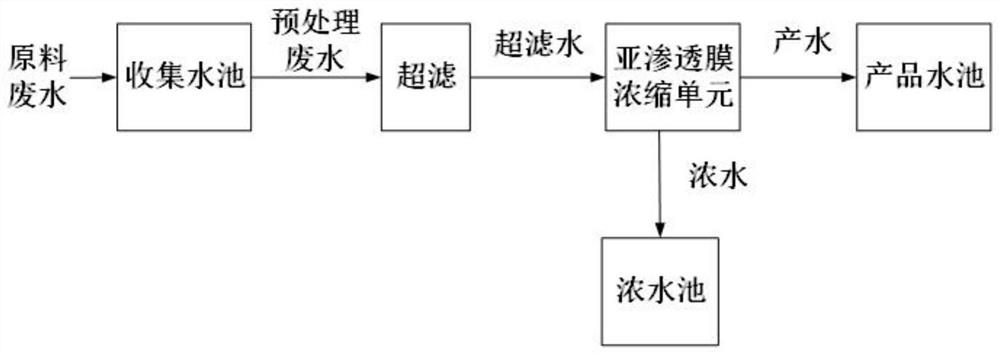

[0073] figure 1 It is a schematic structural diagram of a sub-permeable membrane wastewater treatment system according to Embodiment 1 of the present invention; figure 2 Schematic flow chart of the sub-permeable membrane wastewater treatment process according to Embodiment 1.

[0074] Such as figure 1 As shown, the sub-osmotic membrane wastewater treatment system includes a pretreatment unit for sequentially treating raw wastewater, a sub-osmotic membrane concentration unit, a product pool for collecting the produced water of the sub-osmosis membrane concentration unit, and a concentrated water pool for concentrated water . The pretreatment unit includes a collection pool and ultrafiltration equipment; each treatment unit or equipment is connected by a pipeline; an ultrafiltration water pool is also provided between the ultrafiltration equipment and the sub-permeable membrane concentration unit to accommodate the ultrafiltration product water, and the To buffer and fully v...

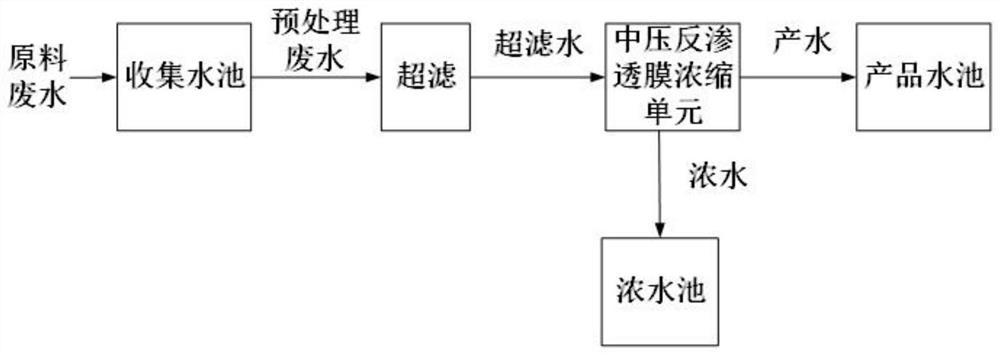

Embodiment approach 2

[0086] The sub-permeable membrane wastewater treatment system and process flow of embodiment 2 are the same as embodiment 1, the difference is that it mainly has the following aspects:

[0087] In this embodiment, in order to ensure the effect of the wastewater pretreatment by adding sodium hypochlorite, by constructing a large-capacity ultrafiltration water production pool, the capacity is at least 20 cubic meters, and the concentration of residual chlorine ions in the ultrafiltration water production pool is controlled by detection: 0.1-0.5ppm. In order to ensure the effect of sodium hypochlorite wastewater pretreatment, while saving costs.

[0088] In Embodiment 2, after the raw wastewater passes through the wastewater zero-discharge treatment system in Embodiment 2, the water quality indicators of the product pool formed are: hardness ≤ 35 mg / l, TDS ≤ 350 mg / l.

[0089] This implementation method treats raw wastewater, which can realize zero discharge of waste gas, reduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com