A kind of method and application of regulating biological activity and bacteriostasis performance of silicon nitride ceramics

A technology of silicon nitride ceramics and biological activity, applied in the field of silicon nitride ceramics, can solve the problems of poor biological activity, poor stability in vivo, low bonding strength between coating and substrate, etc., achieve low cost, easy control of conditions, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

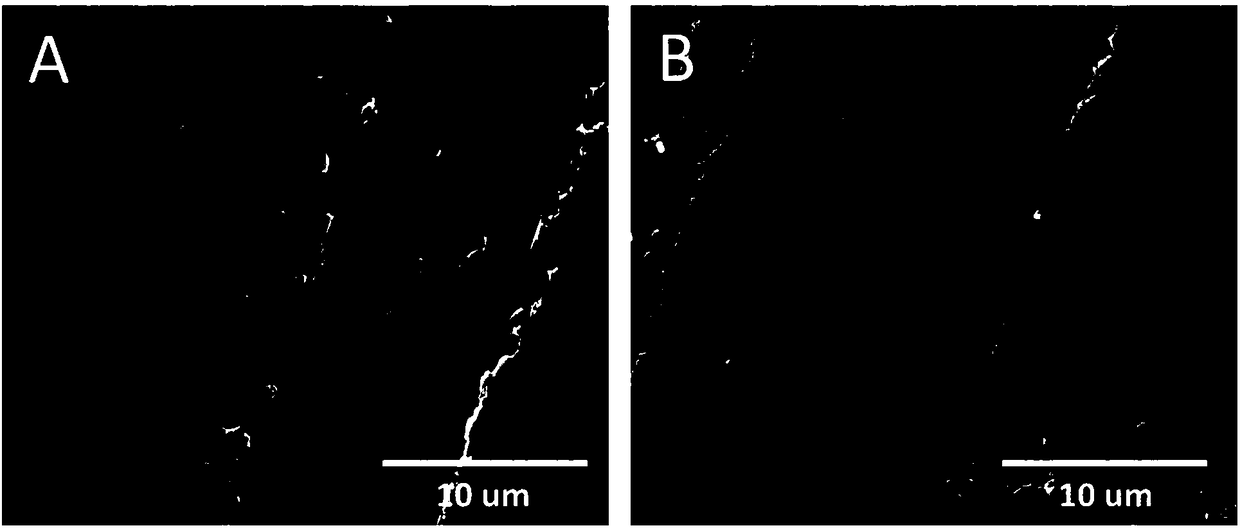

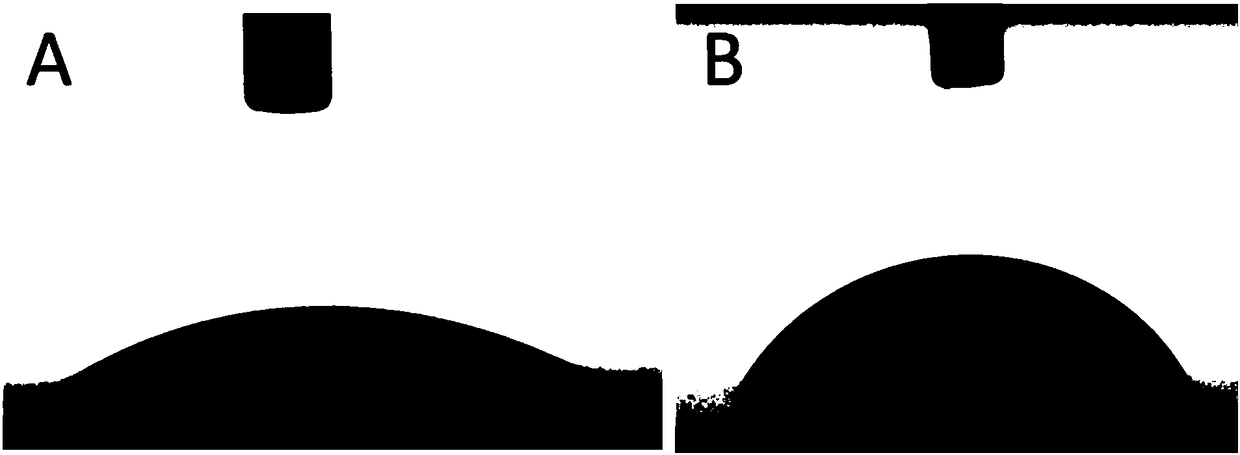

[0033] The silicon nitride ceramic sheet with a size of 10mm×10mm×2mm was ultrasonically cleaned with acetone, methanol, ethanol, and deionized water in sequence, each time for 10 minutes, and dried naturally for later use. The cleaned silicon nitride ceramic sheet was placed in In a 100ml PTFE beaker, add 20ml of a solution with a pH of 3 and a conductivity of 1×10 -4 S / m hydrofluoric acid solution, let it stand at 20°C for 200 minutes, then take it out, wash it with a large amount of deionized water, and dry it at 60°C. Its scanning electron microscope appearance is as follows figure 1 As shown, the contact angle as figure 2 shown.

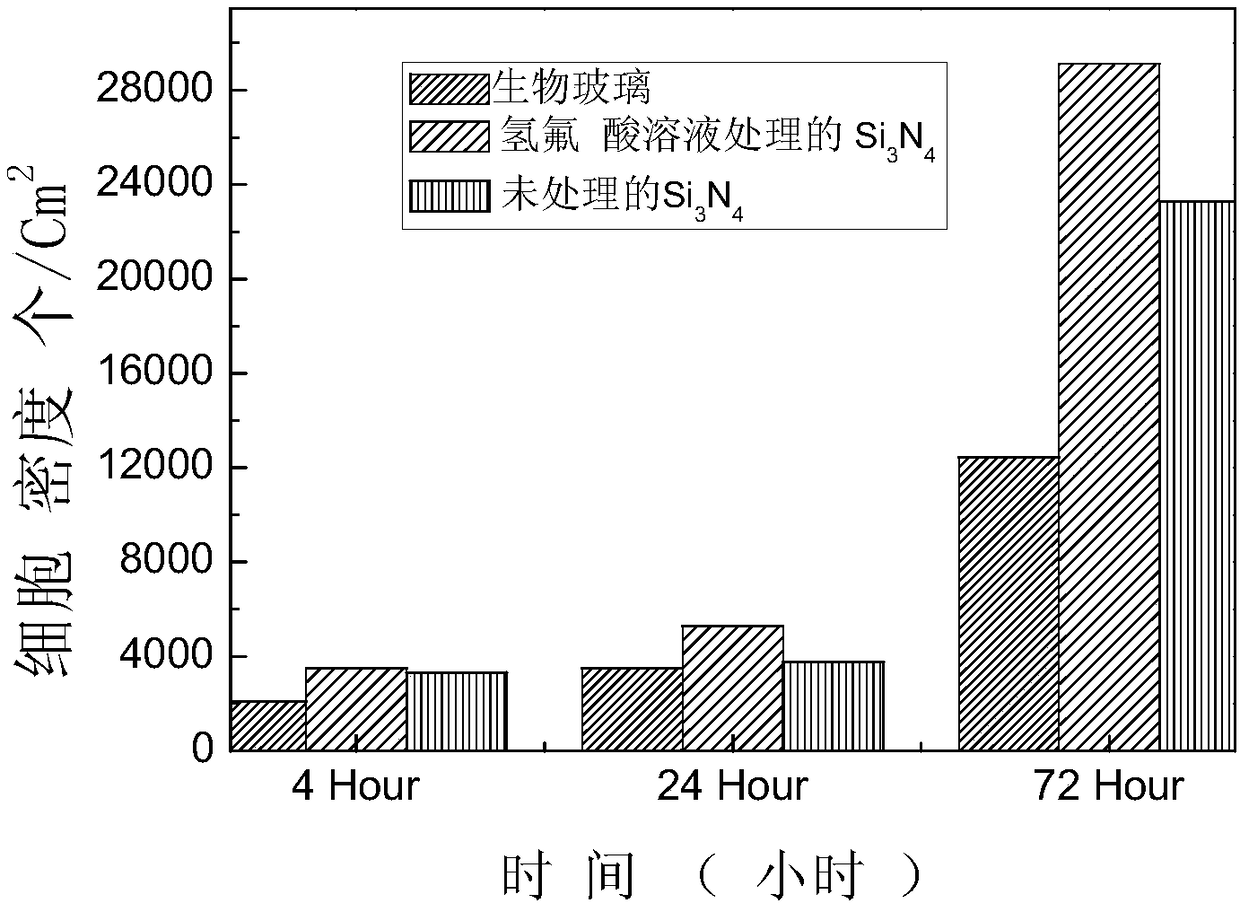

[0034] The silicon nitride ceramics obtained in Example 1, unmodified silicon nitride ceramics and bioglass were sterilized with 75vol% alcohol for 2 hours, washed three times with phosphate buffered saline (PBS), used for cell experiments, and observed in vitro biological activity. The cells were planted on the surface of the material, and...

Embodiment 2

[0039]The silicon nitride ceramic sheet with a size of 10mm×10mm×2mm was ultrasonically cleaned with acetone, methanol, ethanol, and deionized water in sequence, each time for 15 minutes, and dried naturally for later use. The cleaned silicon nitride ceramic sheet was placed in In a 100ml PTFE beaker, add 20ml of a solution with a pH of 5 and a conductivity of 6×10 -4 In the S / m hydrofluoric acid solution, let it stand at 60°C for 100 minutes, then take it out, wash it with a large amount of deionized water, and dry it at 60°C. Its scanning electron microscope appearance is similar to that of Example 1, and the contact angle is 30°.

[0040] The silicon nitride ceramics obtained in Example 2, the unmodified silicon nitride ceramics and the bioglass were subjected to an osteoblast (MC3T3-E1) proliferation experiment. After the sample was sterilized by 75vol% alcohol for 2 hours, it was washed three times with PBS. The cells were planted on the surface of the material, and the ...

Embodiment 3

[0043] The silicon nitride ceramic sheet with a size of 10mm×10mm×2mm was ultrasonically cleaned with acetone, methanol, ethanol, and deionized water in sequence, each time for 20 minutes, and dried naturally for later use. The cleaned silicon nitride ceramic sheet was placed in In a 100ml PTFE beaker, add 20ml of pH 7, conductivity 1×10 -3 S / m mixed solution of hydrofluoric acid and hydrogen peroxide, while adding 1ml of 0.005M AgNO 3 The solution was left to react at 30°C for 60 minutes, then it was taken out and rinsed with a large amount of deionized water, and dried at 60°C. Its scanning electron microscope topography and X-ray energy spectrum are as follows Figure 4 As shown, the silver particles are clearly visible on the surface, which makes the silicon nitride ceramics have antibacterial or antibacterial properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com