A kind of p-toluenesulfonate group gemini quaternary ammonium salt and preparation method thereof

A technology of p-toluenesulfonate and gemini quaternary ammonium salt, which is applied in the direction of sulfonate ester preparation, amino compound preparation, chemical instruments and methods, etc. It can solve the problem of sudden drop in molecular weight, lower corrosion inhibition performance, and can not really meet the requirements of environmental protection and other problems, to achieve the effect of rapid response, increased reaction rate, and not easy to decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

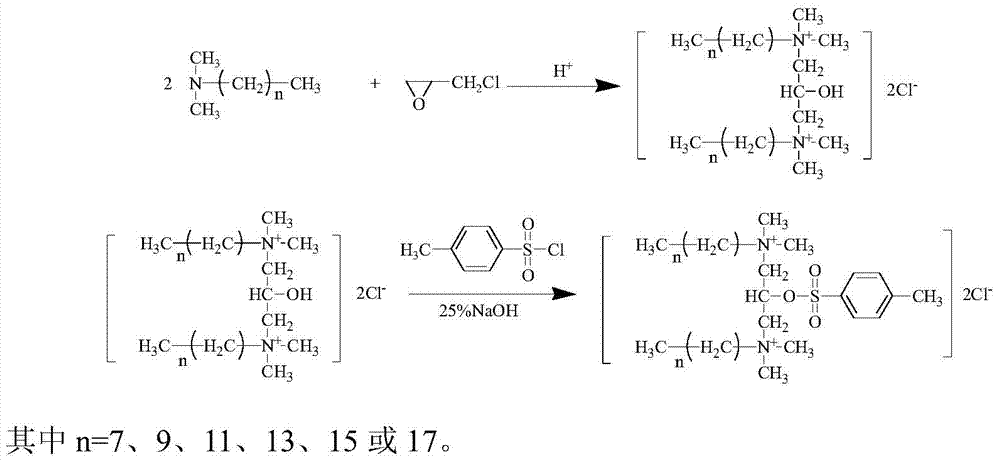

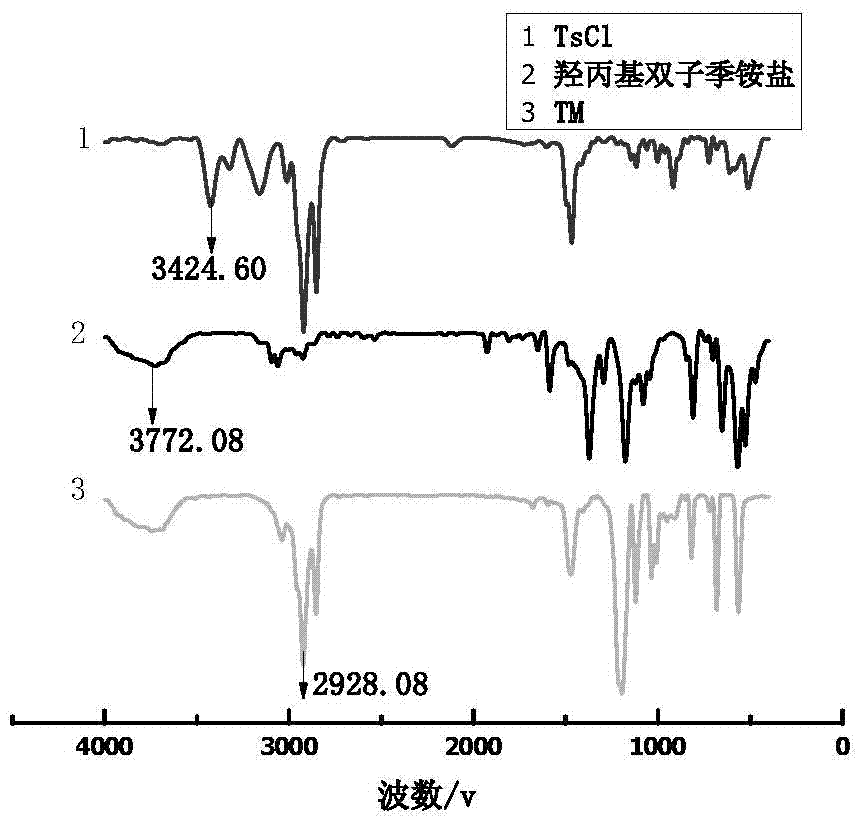

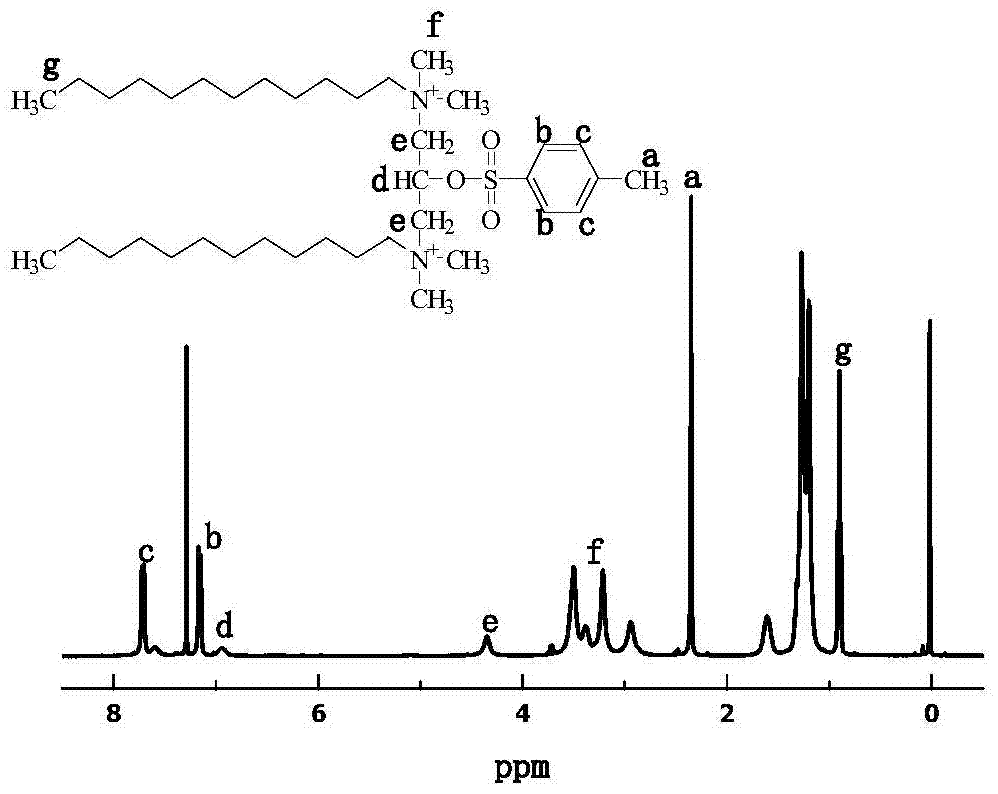

[0034] see figure 1 , 1) Add the weighed 0.02mol of dodecyldimethyl tertiary amine into a 100mL three-necked flask filled with 10mL of isopropanol, heat to 50°C, and then drop 4.0mL of 2.5mol / L hydrochloric acid into it Solution, stirred at 450r / min until uniform. Gradually add 0.01mol of epichlorohydrin to the system dropwise within 30 minutes, and adopt a temperature program at the same time. After 12 hours, the heating was stopped to obtain a crude product. The crude product was evaporated under reduced pressure at 85°C and 0.09MPa to remove the solvent, then dissolved in acetone at 60°C, recrystallized at room temperature, filtered with suction, and redissolved. After repeating three times, dry to obtain hydroxypropyl gemini quaternary ammonium salt; the yield is 87.9%.

[0035] 2) Add 0.01mol of the intermediate product hydroxypropyl gemini quaternary ammonium salt and 0.01mol of p-toluenesulfonyl chloride into a 100mL flask containing 20mL of chloroform, and after stir...

Embodiment 2

[0037]1) Add 0.02mol of dodecyldimethyl tertiary amine into a 100mL three-necked flask filled with 10mL of isopropanol, heat to 50°C, and then drop 4.0mL of 2.5mol / L hydrochloric acid solution into it , Stir at 450r / min until uniform. Gradually add 0.01mol of epichlorohydrin to the system dropwise within 30 minutes, and adopt a temperature program at the same time. After 12 hours, the heating was stopped to obtain a crude product. The crude product was evaporated under reduced pressure at 85°C and 0.09MPa to remove the solvent, then dissolved in acetone at 60°C, recrystallized at room temperature, filtered with suction, and redissolved. After repeating three times, dry to obtain hydroxypropyl gemini quaternary ammonium salt; the yield is 89.13%.

[0038] 2) Add 0.01mol of the intermediate product hydroxypropyl gemini quaternary ammonium salt and 0.01mol of p-toluenesulfonyl chloride into a 100mL flask containing 20mL of chloroform, and after stirring evenly, slowly add dropwi...

Embodiment 3

[0040] 1) Add 0.021mol of dodecyldimethyl tertiary amine into a 100mL three-neck flask filled with 10mL of isopropanol, heat to 50°C, and then drop 4.0mL of 2.5mol / L hydrochloric acid solution into it , Stir at 450r / min until uniform. Gradually add 0.01mol of epichlorohydrin to the system dropwise within 30 minutes, and adopt a temperature program at the same time. After 12 hours, the heating was stopped to obtain a crude product. The crude product was evaporated under reduced pressure at 85°C and 0.09MPa to remove the solvent, then dissolved in acetone at 60°C, recrystallized at room temperature, filtered with suction, and redissolved. After repeating three times, dry to obtain hydroxypropyl gemini quaternary ammonium salt; the yield is 92.1%.

[0041] 2) Add 0.01mol of the intermediate product hydroxypropyl gemini quaternary ammonium salt and 0.013mol of p-toluenesulfonyl chloride into a 100mL flask containing 20mL of chloroform, stir evenly, and slowly add dropwise at 60°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com