Anisotropic conductive adhesive and preparation method thereof

An anisotropic, conductive adhesive technology, applied in the field of conductive adhesives, can solve the problems of fragile joints, poor fluidity of conductive adhesives, and unstable electrical conductivity, and achieve the effect of increasing electrical conductivity and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

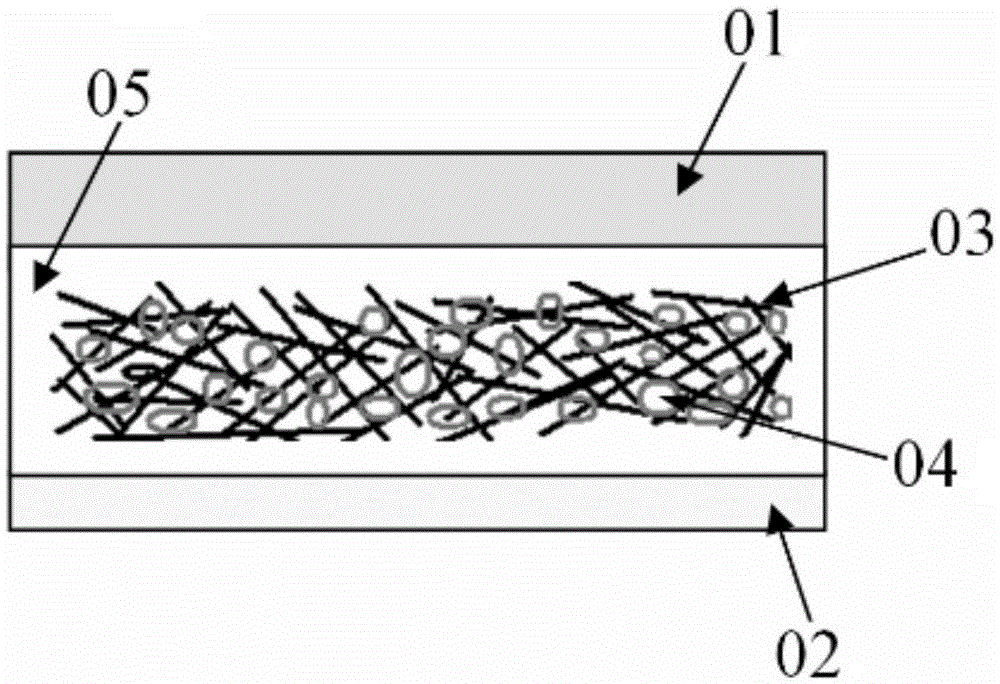

[0032] An anisotropic conductive adhesive, the mass fraction of each component is: n-butyl methacrylate 15%, styrene monomer 9%, hydroxypropyl methacrylate 11%, ethylene glycol dimethacrylate 9% %, conductive particles 35%, silver-plated fibers 21%; conductive particles are copper-plated silver spherical conductive particles, the particle size distribution is within the range of 30-50nm, and the density distribution is 1.5-2.5g / cm 3 within range. In this embodiment, the diameter of the silver-plated fiber is 5-8 μm, the length is 10-20 μm, and the density is 1-2 g / cm 3 .

[0033] The preparation method of conductive glue in the present embodiment is:

[0034] (1) Stirring n-butyl methacrylate and styrene monomer at 60°C (using a DC high-speed mixer at a speed of 1000 rpm) for 1 hour in proportion to obtain a mixture X1;

[0035] (2) Stir hydroxypropyl methacrylate and ethylene glycol dimethacrylate in proportion at 60°C (using a DC high-speed mixer at a speed of 500rpm) for...

Embodiment 2

[0042] An anisotropic conductive adhesive, the mass fraction of each component is: n-butyl methacrylate 10%, styrene monomer 8%, hydroxypropyl methacrylate 10%, ethylene glycol dimethacrylate 15% %, conductive particles 30%, silver-plated fibers 27%; conductive particles are copper-plated silver ball conductive particles, the particle size distribution is in the range of 40-70nm, and the density distribution is 2-3g / cm 3 within range. In this embodiment, the diameter of the silver-plated fiber is 7-10 μm, the length is 15-30 μm, and the density is 1-2g / cm 3 .

[0043] The preparation method of conductive glue in the present embodiment is:

[0044] (1) Stirring n-butyl methacrylate and styrene monomer at 55°C (using a DC high-speed mixer at a speed of 800 rpm) for 1.5 hours in proportion to obtain a mixture X1;

[0045] (2) Stir hydroxypropyl methacrylate and ethylene glycol dimethacrylate in proportion at 55°C (using a DC high-speed mixer at a speed of 600rpm) for 0.5h to o...

Embodiment 3

[0052] An anisotropic conductive adhesive, the mass fraction of each component is: 12% of n-butyl methacrylate, 15% of styrene monomer, 20% of hydroxypropyl methacrylate, 8% of ethylene glycol dimethacrylate %, conductive particles 25%, silver-plated fibers 20%; conductive particles are copper-plated silver ball conductive particles, the particle size distribution is in the range of 30-70nm, and the density distribution is 1.5-3g / cm 3 within range. In this embodiment, the diameter of the silver-plated fiber is 5-10 μm, the length is 10-30 μm, and the density is 1-2g / cm 3 .

[0053] The preparation method of conductive glue in the present embodiment is:

[0054] (1) Stirring n-butyl methacrylate and styrene monomer at 70°C (using a DC high-speed mixer at a speed of 900rpm) for 0.8h in proportion to obtain a mixture X1;

[0055] (2) Stir hydroxypropyl methacrylate and ethylene glycol dimethacrylate in proportion at 70°C (using a DC high-speed mixer at a speed of 400rpm) for 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com