Method for recovering scandium in acid solution

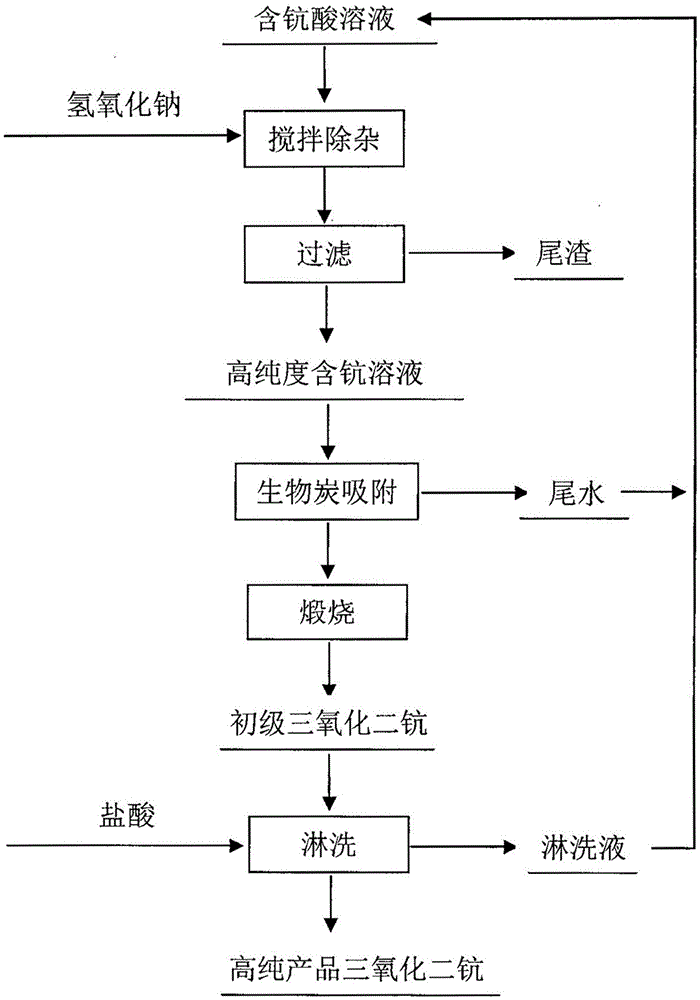

A recovery method and acid solution technology, which is applied in the field of scandium hydrometallurgy, can solve the problems of cumbersome extraction process, low recovery rate of scandium, large amount of reagents, etc., and achieve easy control of process parameters, reduction of reagent consumption, and recovery rate of scandium high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Mix the solution containing scandium acid and sodium hydroxide in a stirrer at a mass ratio of 100:12~15, stir to remove impurities for 50~60min at a temperature of 30~60°C and a stirring intensity of 50~100r / min, and stir to remove impurities. After the impurity is completed, the tailings and high-purity scandium-containing solution are obtained by filtration; the high-purity scandium-containing solution and biochar are mixed in a container at a mass ratio of 100:0.2~0.5, and then the container is placed on a vibrator; when the vibrating frequency is 10~30 times / min, shaking temperature 30~60℃, shaking for 10~15min, solid-liquid separation to obtain tail water and scandium-containing biochar, the tail water is returned as the leaching solvent for scandium extraction; dry scandium-containing biochar Placed in a crucible, calcined in a roasting furnace at 600-750°C for 30-60 minutes to obtain primary scandium trioxide; mix primary scandium trioxide with hydrochloric acid ...

Embodiment 2

[0025] Mix the solution containing scandium acid and sodium hydroxide in a stirrer at a mass ratio of 100:8~12, and stir to remove impurities for 40~50min at a temperature of 30~60°C and a stirring intensity of 50~100r / min. After the impurity is finished, the tailings and high-purity scandium-containing solution are obtained by filtration; the high-purity scandium-containing solution and biochar are mixed in a container at a mass ratio of 100:0.5~0.8, and then the container is placed on a shaker; 10~30 times / min, shaking temperature 30~60℃, shaking for 15~20min, solid-liquid separation to obtain tail water and scandium-containing biochar, the tail water is returned as the leaching solvent for scandium extraction; dry scandium-containing biochar Placed in a crucible, calcined in a roasting furnace at 600-750°C for 30-60 minutes to obtain primary scandium trioxide; mix primary scandium trioxide with hydrochloric acid solution with a concentration of 0.2-0.4mol / L in the exchange c...

Embodiment 3

[0027] Mix the solution containing scandium acid and sodium hydroxide in a stirrer at a mass ratio of 100:5~8, stir to remove impurities for 30~40min at a temperature of 30~60°C and a stirring intensity of 50~100r / min, and stir to remove impurities. After the impurity is completed, the tailings and high-purity scandium-containing solution are obtained by filtration; the high-purity scandium-containing solution and biochar are mixed in a container at a mass ratio of 100:0.8~1, and then the container is placed on a vibrator; when the vibrating frequency is 10~30 times / min, shaking temperature 30~60℃, shaking for 20~30min, solid-liquid separation to obtain tail water and scandium-containing biochar, the tail water is returned as the leaching solvent for scandium extraction; dry scandium-containing biochar Placed in a crucible, calcined in a roasting furnace at 600-750°C for 30-60 minutes to obtain primary scandium trioxide; mix primary scandium trioxide with hydrochloric acid solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com