A kind of solid lubricating multilayer composite film and preparation method thereof

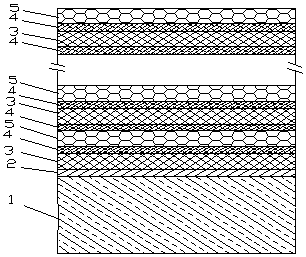

A multi-layer composite film, solid lubrication technology, applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problems of low bonding strength, low friction coefficient and wear rate, insufficient lubrication performance of lubricating film, etc. Achieve the effect of high bonding strength, improved lubrication and wear performance, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] ① Use a stainless steel substrate, grind and polish the surface of the substrate with sandpaper, and then dry it after ultrasonic degreasing and derusting cleaning, then put it in a vacuum chamber, the background vacuum degree is ≤5×10 -3 Pa, the matrix is cleaned by ion bombardment;

[0025] ② Deposition of metal bottom Ti layer: argon pressure of 0.2Pa, metal Ti target power of 12W / cm 2 , the bias voltage is 300V, the ion source power is 0.5kW, the time is 10min, and the thickness is 97nm;

[0026] ③ Turn off the Ti target, turn on the CuNiIn target, and deposit the CuNiIn layer: the argon pressure is 0.5Pa, and the power of the CuNiIn target is 5W / cm 2 , the bias voltage is 40V, the ion source is 0.8kW, the time is 8min, and the thickness is 0.12μm;

[0027] ④ Turn off the CuNiIn target, turn on the Ti target, and deposit the Ti layer of the metal transition layer: the argon pressure is 0.5Pa, and the Ti target power is 5W / cm 2 , the bias voltage is 500V, the io...

Embodiment 2

[0032] ①A titanium alloy substrate is used. After grinding and polishing the surface of the substrate with sandpaper, ultrasonic degreasing, rust removal, cleaning, drying, and putting it in a vacuum chamber, the background vacuum degree is ≤5×10 -3 Pa, the matrix is cleaned by ion bombardment;

[0033] ② Deposition of metal primer Cr layer: argon pressure of 0.5 Pa, metal Cr target power of 9W / cm 2 , the bias voltage is 200V, the ion source is 1.0kW, the time is 20min, and the thickness is 187nm;

[0034] ③Close the Cr target, open the CuNiIn target, and deposit the CuNiIn layer: the argon pressure is 1.0Pa, and the CuNiIn target power is 9W / cm 2 , the bias voltage is 100V, the ion source is 0.6kW, the time is 25min, and the thickness is 0.44μm;

[0035] ④ Turn off the CuNiIn target, turn on the Cr target, and deposit the Cr layer of the intermediate metal transition layer: the argon pressure is 1.0Pa, and the Cr target power is 9W / cm 2 , the bias voltage is 300V, the ion ...

Embodiment 3

[0040] ①Using high-speed steel substrate, after grinding and polishing the surface of the substrate with sandpaper, ultrasonic degreasing, rust removal, cleaning, drying, and putting it in a vacuum chamber, the background vacuum degree is ≤5×10 -3 Pa, the matrix is cleaned by ion bombardment;

[0041] ② Deposition of the W layer of the metal base layer: the argon pressure is 0.8Pa, and the power of the metal W target is 5W / cm 2 , the bias voltage is 100V, the ion source is 1.5kW, the time is 30min, and the thickness is 0.27μm;

[0042] ③ Turn off the W target, turn on the CuNiIn target, and deposit the CuNiIn layer: the argon pressure is 2.0Pa, and the CuNiIn target power is 12W / cm 2 , the bias voltage is 180V, the ion source is 0.4kW, the time is 50min, and the thickness is 0.69μm;

[0043] ④ Turn off the CuNiIn target, turn on the W target, and deposit the intermediate metal transition layer W layer: the argon pressure is 2.0Pa, and the W target power is 12W / cm 2 , the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com