Ultrahigh molecular weight polyethylene (PE) composite plastic water supply pipe

An ultra-high molecular weight, composite plastic technology, applied in the field of ultra-high molecular weight PE composite plastic water supply pipes, can solve the problems of easy corrosion and rust, poor impact resistance, low compressive strength, etc. performance, the effect of increasing the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

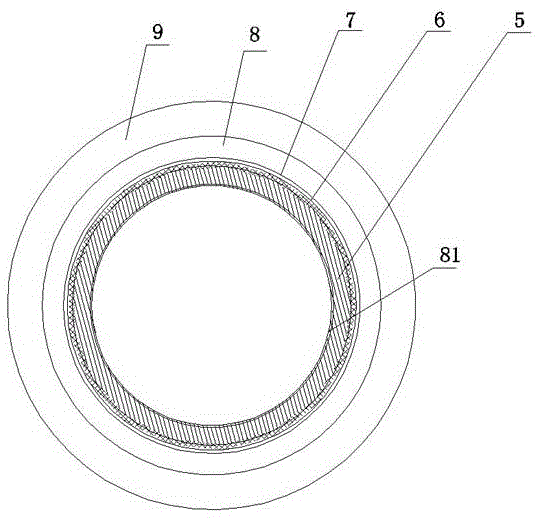

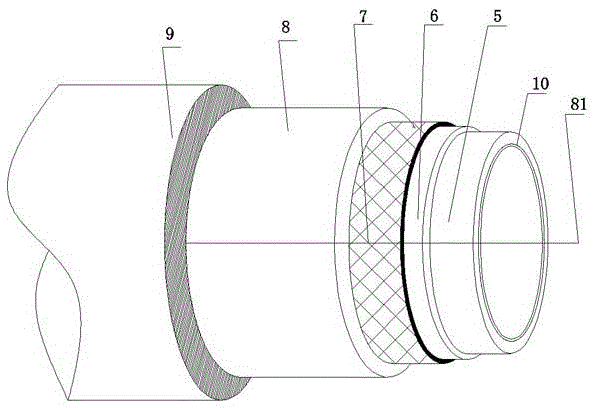

[0014] Embodiment 1: as figure 1 , as shown in 2, the innermost layer of the ultra-high molecular weight PE composite plastic water supply pipe is a UHMWPE core tube 5, the UHMWPE core tube is wrapped with a first bonding layer 6, and the outer layer 6 of the first bonding layer is wrapped with a stainless steel wire mesh layer 7, and the stainless steel mesh Layer 7 is wrapped with PE intermediate bonding layer 8, and the outer wall of PE intermediate bonding layer 8 is wrapped with HDPE weather-resistant layer 9; An embedded metal wire 81 is also provided between the PE intermediate bonding layer and the HDPE weather-resistant layer. The embedded metal wire 81 and the stainless steel wire mesh layer 7 form a data transmission loop. If the sensor is installed in the pipeline, the embedded metal wire and the stainless steel mesh layer can be directly connected to the sensor to form a data transmission channel, which greatly reduces the wiring of the sensor. trouble.

[0015]...

Embodiment 2

[0020] Embodiment 2: as figure 1 , as shown in 2, the innermost layer of the ultra-high molecular weight PE composite plastic water supply pipe is a UHMWPE core tube 5, the UHMWPE core tube is wrapped with a first bonding layer 6, and the outer layer 6 of the first bonding layer is wrapped with a stainless steel wire mesh layer 7, and the stainless steel mesh Layer 7 is wrapped with PE intermediate bonding layer 8, and the outer wall of PE intermediate bonding layer 8 is wrapped with HDPE weather-resistant layer 9;

[0021] UHMWPE core tube 5: Put 100 parts of UHMWPE resin, 2 parts of nano-silica, 7 parts of calcium sulfate whiskers, 7 parts of 3A molecular sieve, and 5 parts of palygor into the hopper of the first extruder according to the weight ratio.

[0022] The first binding layer 6: mix 100 parts of PE resin, 3 parts of nano-silica, 3 parts of 3A molecular sieve, and 5 parts of ethylene-α-octene copolymer according to the weight ratio and put them into the hopper of the...

Embodiment 3

[0026] Embodiment 3: as figure 1 , as shown in 2, the innermost layer of the ultra-high molecular weight PE composite plastic water supply pipe is a UHMWPE core tube 5, the UHMWPE core tube is wrapped with a first bonding layer 6, and the outer layer 6 of the first bonding layer is wrapped with a stainless steel wire mesh layer 7, and the stainless steel mesh Layer 7 is wrapped with PE intermediate bonding layer 8, and the outer wall of PE intermediate bonding layer 8 is wrapped with HDPE weather-resistant layer 9;

[0027] UHMWPE core tube 5: Put 100 parts of UHMWPE resin, 1-2 parts of nano silicon dioxide, 6 parts of calcium sulfate whisker, 6 parts of 3A molecular sieve, and 4 parts of palygor into the hopper of the first extruder according to the weight ratio.

[0028] First bonding layer 6: mix 100 parts of PE resin, 2.5 parts of nano silicon dioxide, 2.5 parts of 3A molecular sieve, and 4 parts of ethylene-α-octene copolymer into the hopper of the second extruder accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com