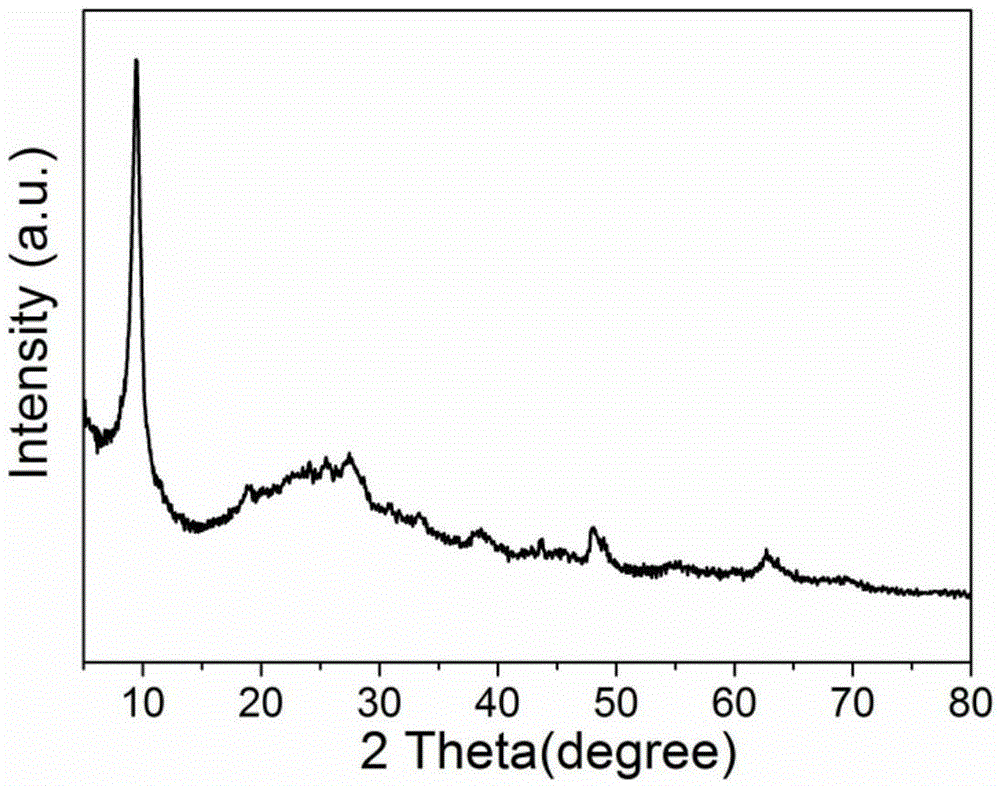

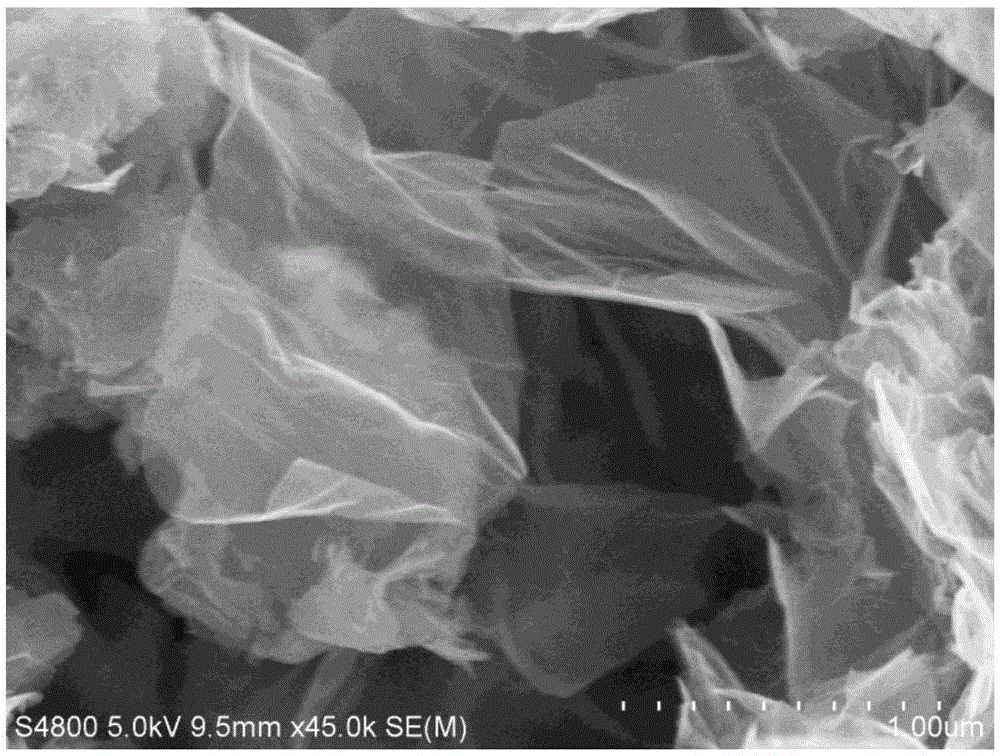

Hierarchical brookite titanium oxide/graphene composite material and preparation method and application thereof

A brookite-type, hierarchical structure technology, applied to structural parts, electrical components, battery electrodes, etc., can solve problems such as easy agglomeration, reduced capacity, and small nanoparticle size, so as to improve electrochemical performance, promote formation, The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of brookite type titanium oxide / graphene composite material with hierarchical structure, specifically comprising the following steps:

[0037] 1) Dissolve 0.8mL deionized water and 1.8mL oleylamine in 200mL absolute ethanol, stir for 20min and mix evenly to obtain the mixed solution I;

[0038] 2) Add 4.5mL of isobutyl titanate to the mixture I obtained in step 1), and stir thoroughly for 2 hours (stirring temperature is 25°C, stirring speed is 700r / min), forming a uniform milky white suspension, after standing get white precipitate;

[0039] 3) Add 20mL of deionized water and 10mL of graphene oxide into 20mL of absolute ethanol, mix well to obtain a mixed solution II, then weigh 0.25 g of the white precipitate obtained in step 2) and add it to the obtained mixed solution II, ultrasonically treat for 2 hours, and then add 20mL of ethylenediamine, continue ultrasonic treatment for 1h to obtain mixed solution III;

[0040] 4) Put the mixed liquid II...

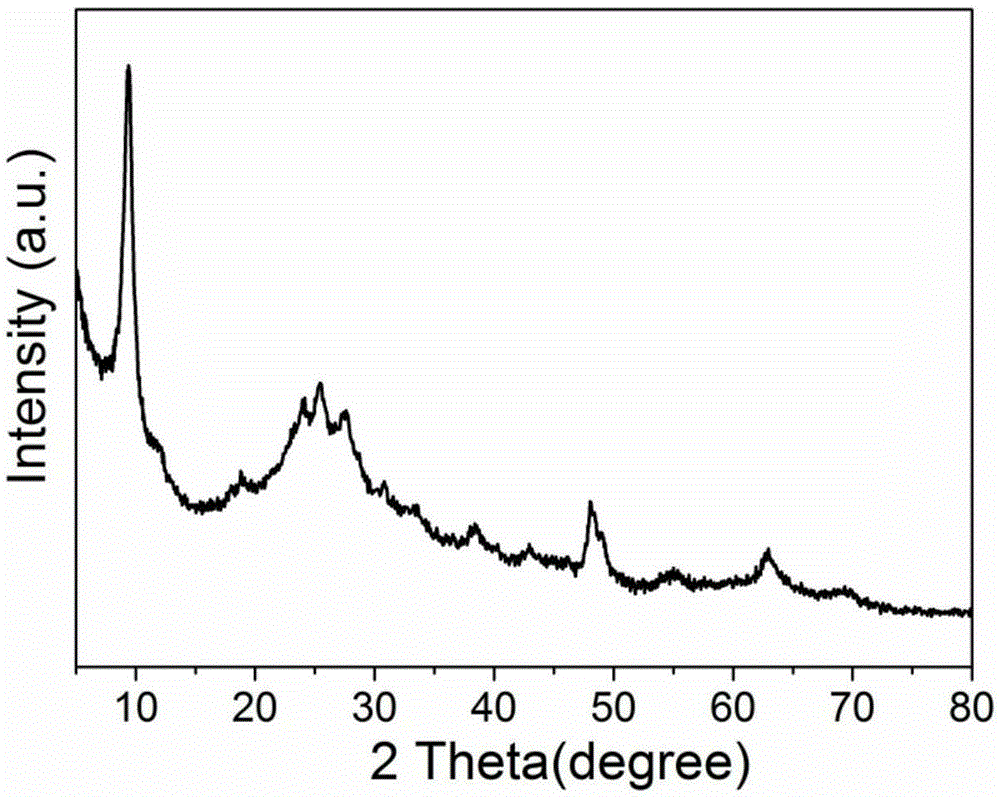

Embodiment 2

[0043] A preparation method of brookite type titanium oxide / graphene composite material with hierarchical structure, specifically comprising the following steps:

[0044] 1) Dissolve 0.8mL deionized water and 1.8mL oleylamine in 200mL absolute ethanol, stir for 20min and mix evenly to obtain the mixed solution I;

[0045] 2) Add 4 mL of isobutyl titanate to the mixed solution I obtained in step 1), and stir thoroughly for 2 hours (stirring temperature is 10°C, stirring speed is 900r / min), forming a uniform milky white suspension, which is obtained after standing still white precipitate;

[0046] 3) Add 20mL of deionized water and 20mL of graphene oxide into 20mL of absolute ethanol, mix well to obtain the mixed solution II, then weigh 0.25g of the white precipitate obtained in step 2) and add it to the obtained mixed solution II, sonicate for 2h, and then add 20mL of ethylenediamine, continue ultrasonic treatment for 1h to obtain mixed solution III;

[0047]4) Put the mixed ...

Embodiment 3

[0051] A preparation method of brookite type titanium oxide / graphene composite material with hierarchical structure, specifically comprising the following steps:

[0052] 1) Dissolve 0.8mL deionized water and 1.8mL oleylamine in 200mL absolute ethanol, stir for 20min and mix evenly to obtain the mixed solution I;

[0053] 2) Add 4.5mL of isobutyl titanate to the mixed solution I obtained in step 1), and fully stir for 2 hours (stirring temperature is 60°C, stirring speed is 1200r / min), forming a uniform milky white suspension, which is obtained after standing still white precipitate;

[0054] 3) Add 20mL of deionized water and 40mL of graphene oxide into 20mL of absolute ethanol, mix well to obtain a mixed solution II, then weigh 0.25 g of the white precipitate obtained in step 2) and add it to the obtained mixed solution II, ultrasonicate for 3 hours, and then add 20mL of ethylenediamine, and continue ultrasonic treatment for 2h to obtain the mixed solution III;

[0055] 4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com