Nickel base trinary positive electrode material and preparation method thereof

A kind of positive electrode material, nickel-based technology, applied in the field of nickel-based ternary positive electrode materials and its preparation, can solve the problems of easy to be corroded cycle life, limit large-scale commercial application, high residual alkali content on the surface, etc. Sensitive, improve electrochemical performance, reduce the effect of residual lithium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The invention provides a method for preparing a nickel-based ternary positive electrode material, comprising the following steps:

[0046] 1) After mixing and calcining the nickel-based material precursor and lithium salt, the nickel-based material is obtained;

[0047] The chemical formula of the nickel-based material is as shown in formula (I),

[0048] LiNi 1-x-y co x mn y o 2 (I); Wherein, (1-x-y)≥0.5, x>0, y>0;

[0049] 2) Reacting the nickel-based material obtained in the above steps with a coupling agent in an organic solvent, and then roasting to obtain a nickel-based ternary positive electrode material.

[0050] The preferred principles of the present invention, such as the selection and proportion of the raw materials, are consistent with those of the aforementioned nickel-based ternary cathode materials, and will not be repeated here.

[0051] In the invention, firstly, the nickel-based material precursor is mixed and calcined with lithium salt to obtai...

Embodiment 1

[0070] Nickel-based Ni 0.8 co 0.1 mn 0.1 (OH) 2 The precursor and lithium hydroxide were uniformly mixed according to the molar ratio of Li:(Ni+Co+Mn)=1.03:1, then calcined at 800°C for 10 hours at a high temperature, cooled, pulverized, and sieved to obtain an uncoated nickel-based positive electrode material, This is the uncoated material.

[0071] Add the uncoated nickel-based positive electrode material obtained above into absolute ethanol, the mass ratio of nickel-based ternary positive electrode material to absolute ethanol is 1:2. Add the titanate coupling agent at a mass ratio of 0.01:1, control the reaction temperature of the system at 55°C, and the stirring speed at 400 rpm. After reacting for 1 hour, filter while it is hot, and roast at a constant temperature of 300°C 2h, the nickel-based ternary positive electrode material coated with the decomposed oxide of the titanate coupling agent was prepared, which was the coated material.

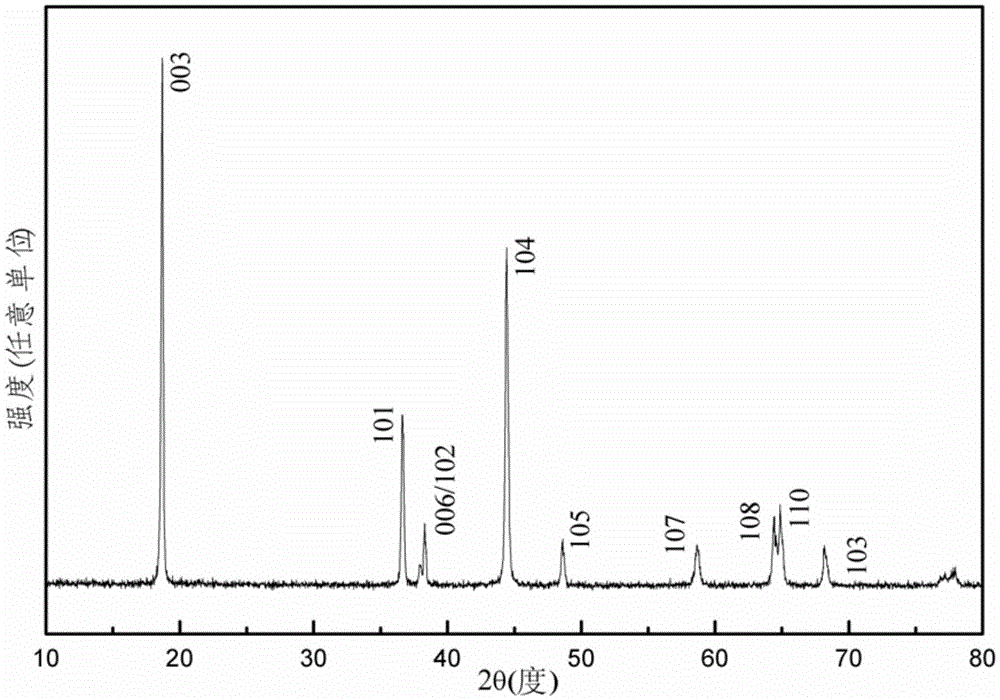

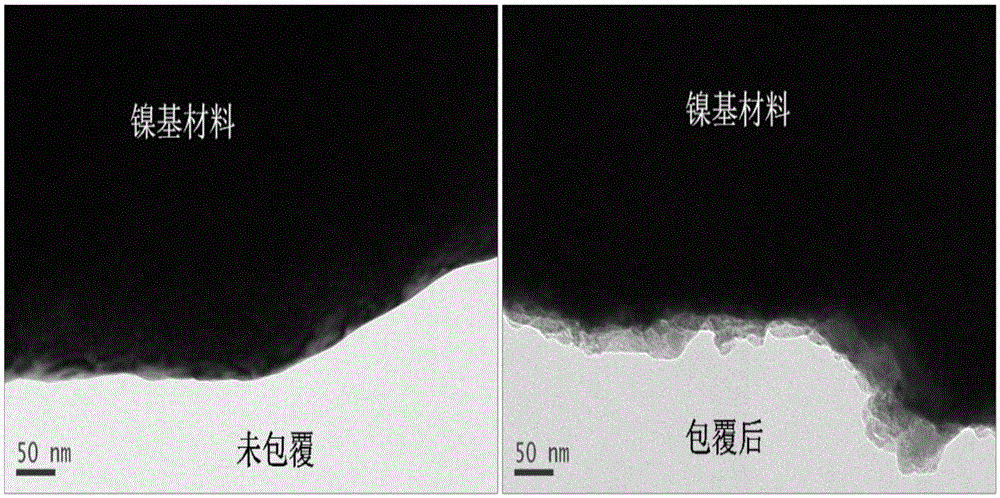

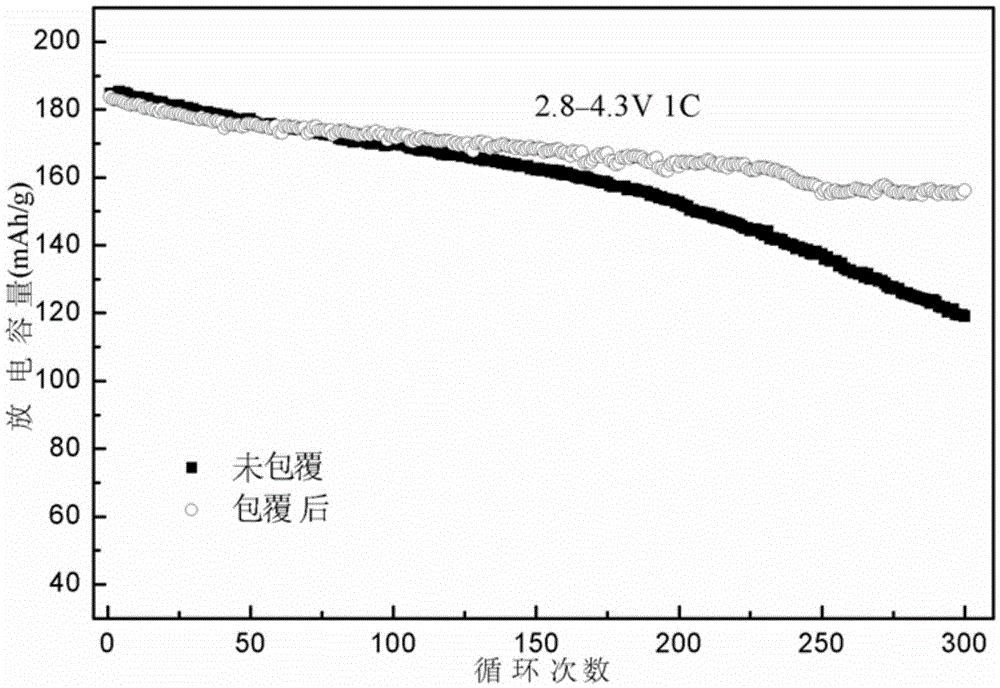

[0072] see figure 1 , figu...

Embodiment 2

[0080] Nickel-based Ni 0.5 co 0.2 mn 0.3 (OH) 2 The precursor and lithium carbonate were uniformly mixed according to the molar ratio of Li:(Ni+Co+Mn)=1.04:1, then calcined at 900°C for 12 hours at high temperature, cooled, pulverized, and sieved to obtain nickel-based materials.

[0081] Add the nickel-based material obtained above into isopropanol, the mass ratio of the nickel-based ternary positive electrode material to isopropanol is 1:3, after stirring at a high speed and dispersing, the mass ratio with the nickel-based ternary positive electrode material is Aluminate coupling agent was added in an amount of 0.02:1, the reaction temperature of the control system was 60°C, and the stirring speed was 500 rpm. After reacting for 1.5 hours, it was filtered while it was hot, and roasted at a constant temperature of 400°C for 3 hours. Aluminate coupling agent decomposes oxide-coated nickel-based ternary cathode materials.

[0082] The coated nickel-based ternary positive el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com