Negative electrode piece of alpha-ZnMoO4 lithium ion battery and preparation method of negative electrode piece

A lithium-ion battery, -znmoo4 technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of organic solvent environment, expensive NMP, high volatilization temperature, etc., to improve performance, promote battery performance, reduce The effect of interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of α-ZnMoO 4 The preparation method of lithium-ion battery negative plate, comprises the following steps:

[0027] Step 1: Dissolve the zinc salt and molybdate with a molar ratio of 1:1 in distilled water respectively, and stir magnetically for 10 minutes to fully dissolve, wherein the molybdate is ammonium molybdate or sodium molybdate, and the zinc salt is zinc nitrate or zinc chloride;

[0028] Step 2: Add the molybdate solution dropwise into the zinc salt solution at a rate of 1-3 mL / min, stir for 30 min, and stand at room temperature for 1-5 days to obtain the zinc molybdate precursor material;

[0029] Step 3: centrifuge the zinc molybdate precursor material obtained in step 2 at 8000-9000r / min for 10-15min, wash it alternately with absolute ethanol and distilled water for 3-6 times, and then dry it in an oven at 60°C. Obtain zinc molybdate precursor;

[0030] Step 4: Put the zinc molybdate precursor obtained in Step 3 into a muffle furnace for heat trea...

Embodiment 1

[0034] Step 1: Dissolve zinc nitrate and sodium molybdate with a molar ratio of 1:1 in distilled water respectively, and magnetically stir for 10 minutes to fully dissolve;

[0035] Step 2: adding the sodium molybdate solution dropwise into the zinc nitrate solution at a rate of 1 mL / min, stirring for 30 min, and standing for a reaction at room temperature for 5 days to obtain the zinc molybdate precursor material;

[0036] Step 3: Centrifuge the zinc molybdate precursor material obtained in step 2 at 8000r / min for 10 minutes, wash it with absolute ethanol and distilled water alternately for 4 times, and then dry it in an oven at 60°C to obtain the zinc molybdate precursor ;

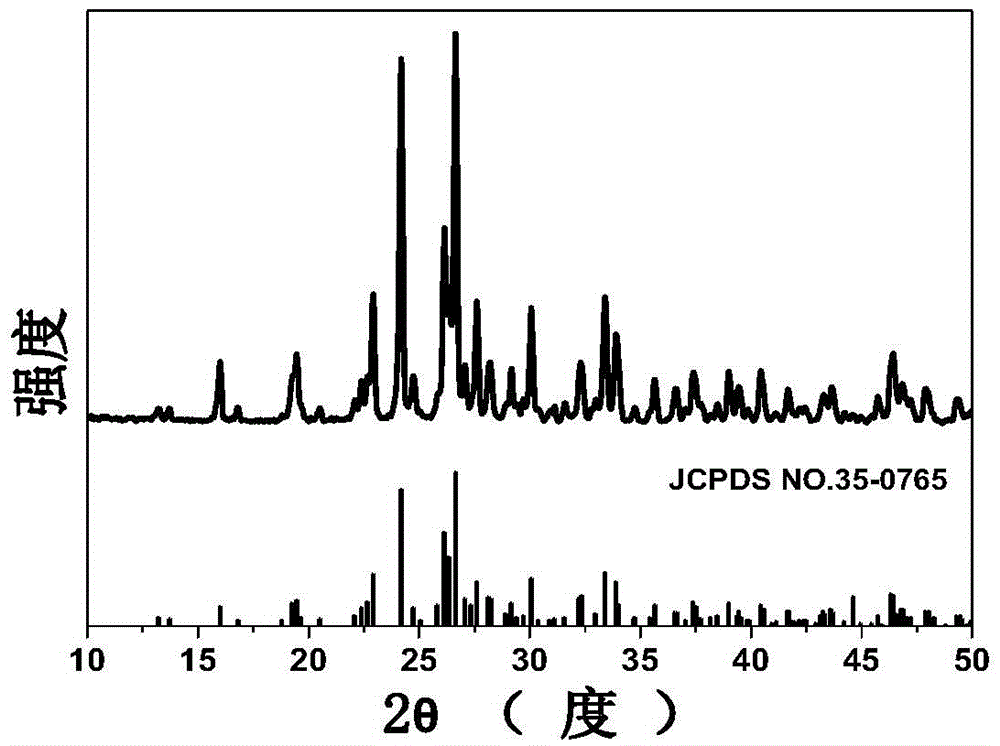

[0037] Step 4: Put the zinc molybdate precursor obtained in Step 3 into a muffle furnace for heat treatment at 600°C for 3 hours, and then naturally cool to room temperature to obtain α-ZnMoO 4 Lithium-ion battery anode materials;

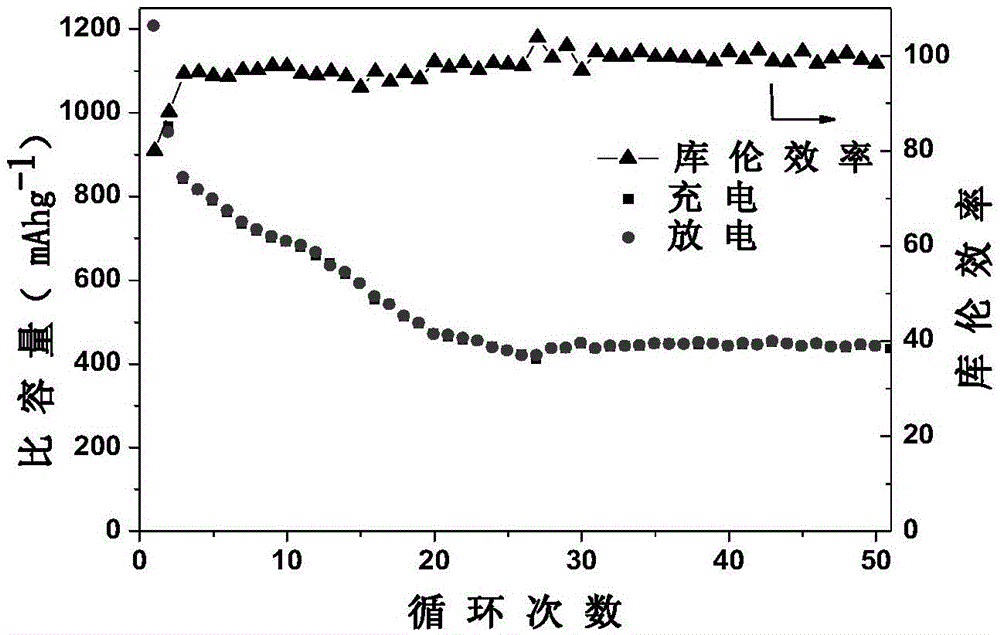

[0038] Step 5: Add α-ZnMoO 4 Mix it with sodium carboxymethyl cellulo...

Embodiment 2

[0042] Step 1: Dissolve zinc chloride and sodium molybdate with a molar ratio of 1:1 in distilled water respectively, and magnetically stir for 10 minutes to fully dissolve;

[0043] Step 2: adding the sodium molybdate solution dropwise into the zinc chloride solution at a rate of 2 mL / min, stirring for 30 min, and standing at room temperature for 1 d to obtain the zinc molybdate precursor material;

[0044] Step 3: Centrifuge the zinc molybdate precursor material obtained in step 2 at 8500r / min for 10 minutes, wash it alternately with absolute ethanol and distilled water for 5 times, and then dry it in an oven at 60°C to obtain the zinc molybdate precursor ;

[0045] Step 4: Put the zinc molybdate precursor obtained in Step 3 into a muffle furnace for heat treatment at 500°C for 3 hours, and then naturally cool to room temperature to obtain α-ZnMoO 4 Lithium-ion battery anode materials;

[0046] Step 5: Add α-ZnMoO 4 Mix it with sodium carboxymethyl cellulose and acetylene b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com