Fluorochrome monomer, copolymeric fluorescent polyurethane emulsion and fluorescent polyurethane-acrylic ester copolymer emulsion as well as preparation methods thereof

A technology of polyurethane emulsion and fluorescent dye, which is applied in the direction of luminescent materials, organic dyes, chemical instruments and methods, etc., and can solve the problems affecting the mechanical properties of water-based polyurethane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The fluorescent dye monomer is prepared by reacting a naphthalene anhydride compound and a hydroxyl functional agent to obtain a dihydroxy-containing intermediate product, and then the intermediate product is subjected to a substitution reaction with a nucleophilic agent. Specifically, the preparation method of the fluorescent dye monomer comprises the following steps:

[0016] S11, dissolving the naphthalene anhydride compound and the hydroxyl functional reagent in the first solvent, and reacting at the first reaction temperature for the first reaction time to obtain an intermediate product;

[0017] S12, dissolving the intermediate product and the nucleophile in a second solvent, and reacting at a second reaction temperature for a second reaction time to prepare a fluorescent dye monomer.

[0018] In step S11, the naphthalene anhydride compound is halogenated naphthalene anhydride and its derivatives, such as: 4-chloro-1,8-naphthalene anhydride, 4-bromo-1,8-naphthalen...

Embodiment 1

[0053] Embodiment 1—copolymerization fluorescent polyurethane emulsion

[0054] (1) Synthesis of fluorescent dye monomer (A): 4.16 grams of 4-bromo-1,8-naphthalene anhydride, 4.10 grams of 2-amino-1,3-propanediol and 100 milliliters of ethanol are added in a single-necked flask, stirred and heated to React at 80°C for 4 hours. The ethanol was distilled off under reduced pressure, and then 300 ml of water was added, followed by standing, filtering, washing the filter cake with water three times and vacuum drying to obtain the intermediate product I.

[0055] Add 3.5 grams of intermediate product I, 1.62 grams of sodium methoxide and 80 milliliters of methanol into a one-necked flask, stir and raise the temperature to 75° C. for 5 hours. Methanol was distilled off under reduced pressure, and then 200 ml of water was added, followed by standing, filtering, washing the filter cake with water three times and vacuum drying to obtain the fluorescent dye monomer (A).

[0056] (2) Pr...

Embodiment 2

[0058] Embodiment 2—copolymerization fluorescent polyurethane emulsion

[0059] (1) Synthesis of fluorescent dye monomer (A): same as in Example 1.

[0060] (2) Preparation of copolymerized fluorescent polyurethane emulsion: add 10 grams of isophorone diisocyanate, 12.5 grams of N210 and 2 drops of stannous octoate into a three-necked flask, stir and react at 80°C for 1.5 hours; then add 1.34 grams of dihydroxy Methylbutyric acid, 1.2 grams of neopentyl glycol and 0.23 grams of fluorescent dye monomer (A) were reacted at 80 ° C for 4 hours; after cooling to 30 ° C, 5 ml of acetone was added to stir to reduce viscosity, and then 1 g of triethylamine was added to neutralize After 30 minutes, 75 milliliters of water was added, stirred for 40 minutes, and acetone was evaporated under reduced pressure to obtain a copolymerized fluorescent polyurethane emulsion.

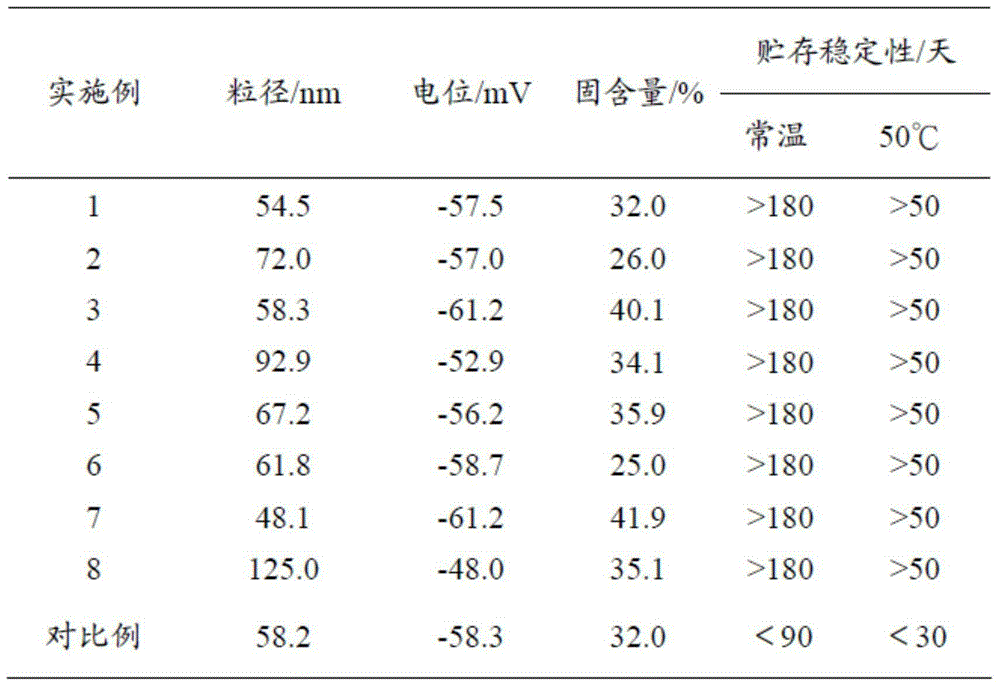

[0061] The properties of the obtained fluorescent emulsion are shown in Table 1, and the color fastness to light of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com