Supercritical carbon dioxide thickening agent as well as preparation method and application thereof

A technology of thickener and catalyst, which is applied in the field of supercritical carbon dioxide thickener, can solve the problems of environmental friendliness and high-efficiency thickening at the same time, and achieve no water-sensitive water lock damage, high yield, and good thickening effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

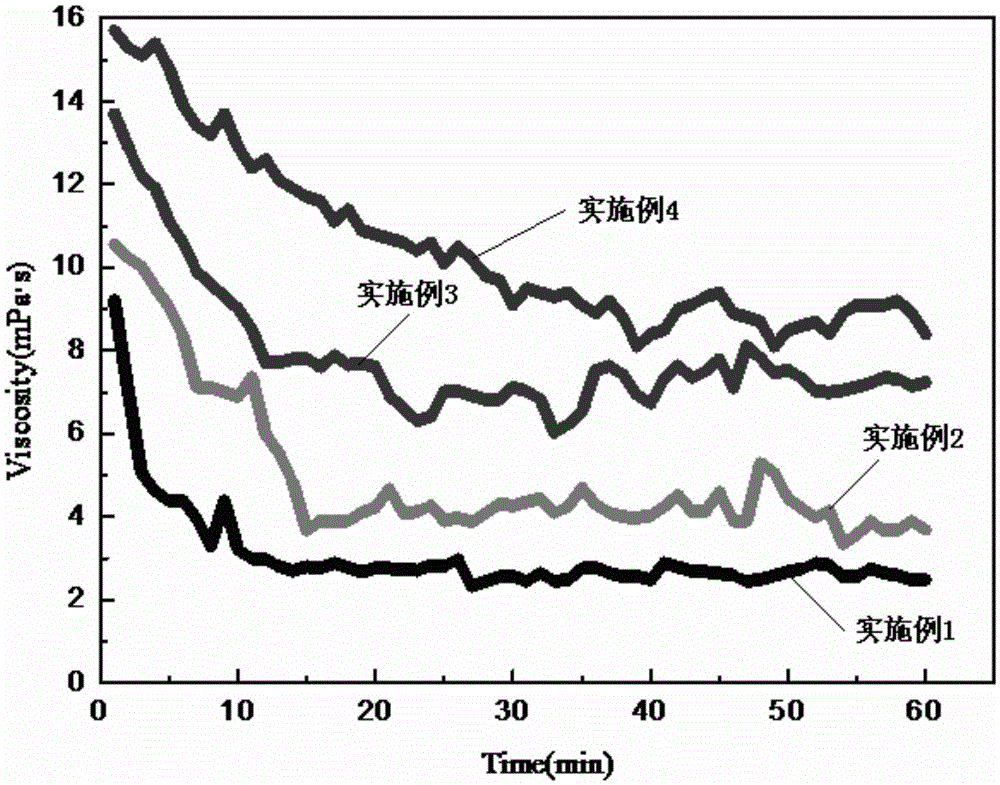

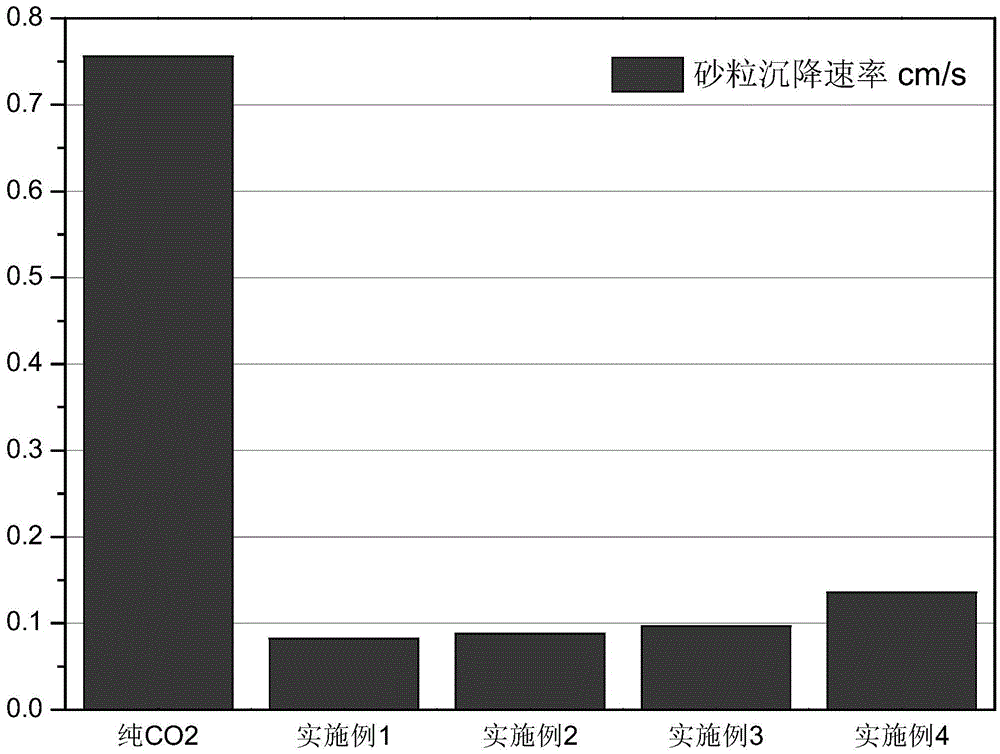

Embodiment 1

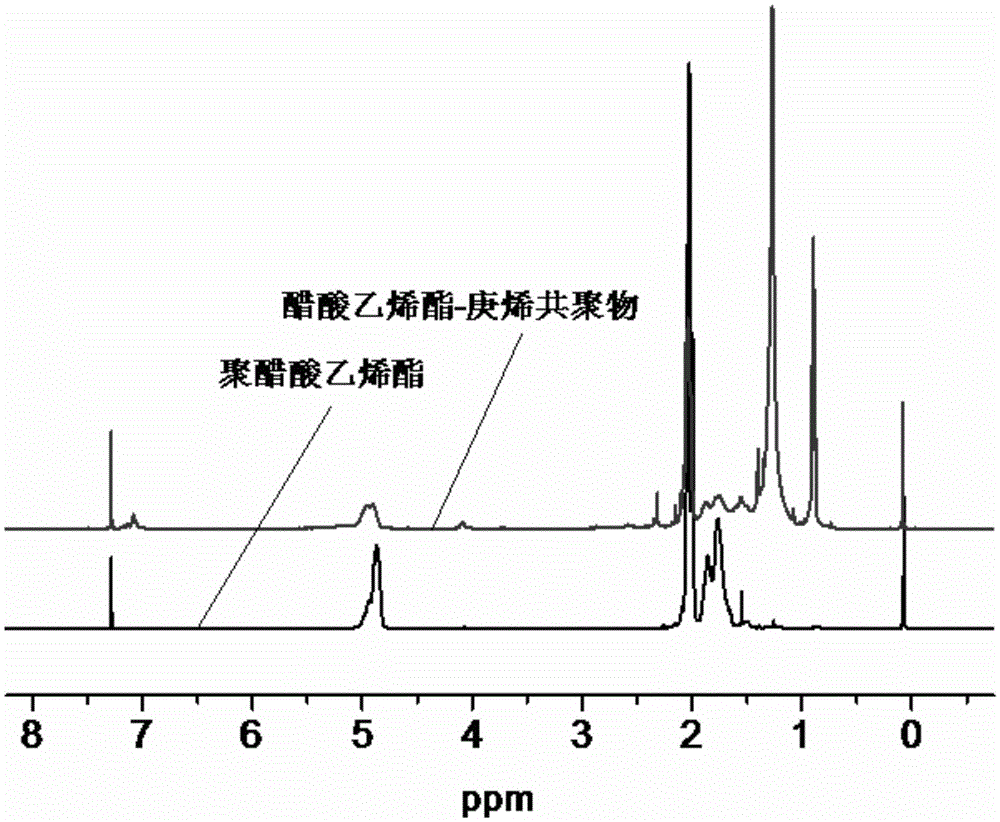

[0063] Under the condition of nitrogen, add 0.8g refined azobisisobutyronitrile (AIBN) initiator in the three-necked flask equipped with reflux condenser and magnet, then inject 35mL vinyl acetate and 120mL chloroform, Reflux reaction at 62°C for 5h. After the reaction is finished, the solvent chloroform and unreacted vinyl acetate monomer are distilled off under reduced pressure to obtain a polyvinyl acetate telomer. The polyvinyl acetate telomer was dissolved in 30 mL of tetrahydrofuran and then refluxed at 62°C for 5 h for purification. After the reflux was completed, tetrahydrofuran was distilled off under reduced pressure, and the purified polyvinyl acetate telomer was dried in a vacuum drying oven to constant weight.

[0064] Add 50mL of p-xylene to a three-necked flask with a ventilation tube (argon gas), reflux condenser and stirring magnet, and add 0.2g of CuCl, 19.8g of 1-heptene, 0.70g of PMDETA, and 25g of polyvinyl acetate to adjust Polymer, wherein, the molar r...

Embodiment 2

[0069] Under nitrogen, add 1.0 g of refined azobisisobutyronitrile (AIBN) initiator into a three-necked flask equipped with a reflux condenser and a magnet, then inject 50 mL of methyl methacrylate, 200 mL of chloroform , Reflux reaction at 60°C for 6h. After the reaction was completed, the solvent trichloromethane and unreacted methyl methacrylate monomer were distilled off under reduced pressure to obtain a polymethyl methacrylate telomer. The polymethyl methacrylate telomer was dissolved in 40 mL of tetrahydrofuran and then refluxed at 60° C. for 4 h for purification. After the reflux was completed, tetrahydrofuran was distilled off under reduced pressure, and the purified polymethyl methacrylate telomer was dried in a vacuum drying oven to constant weight.

[0070]Add 40mL of p-xylene to a three-necked flask with a ventilation tube (argon), a reflux condenser, and a stirring magnet, and add 0.3g of CuBr, 23.6g of 1-octene, 0.48g of TMEDA, and 20g of polymethylmethacrylate...

Embodiment 3

[0074] Under nitrogen, add 0.2g of refined azobisisobutyronitrile (AIBN) initiator into a three-necked flask equipped with a reflux condenser and a magnet, then inject 60mL of acrylic acid and 160mL of chloroform, at 66°C Under the condition of reflux reaction for 7h. After the reaction is completed, the solvent chloroform and unreacted acrylic acid monomers are distilled off under reduced pressure to obtain a polyacrylic acid telomer. The polyacrylic acid telomer was dissolved in 50 mL of tetrahydrofuran and then refluxed at 66° C. for 8 h for purification. After the reflux was completed, tetrahydrofuran was distilled off under reduced pressure, and the purified polyacrylic acid telomer was dried in a vacuum drying oven to constant weight.

[0075] Add 60mL of p-xylene to a three-necked flask with a ventilation tube (argon), a reflux condenser, and a stirring magnet, and add 0.4g of CuI, 26.5g of 1-nonene, 0.66g of 2,2-bipyridine, 30g of Polyacrylic acid telomer, wherein th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Shear viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com