PVC/TPU (polyvinyl chloride/thermoplastic polyurethane) oil-resistant flame-retardant thermoplastic elastomer for new energy automobile charging pile cables

A thermoplastic elastomer, new energy vehicle technology, used in insulated cables, plastic/resin/wax insulators, cables, etc., can solve the problems of difficult oil resistance, high price, etc., and achieve the effect of high mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

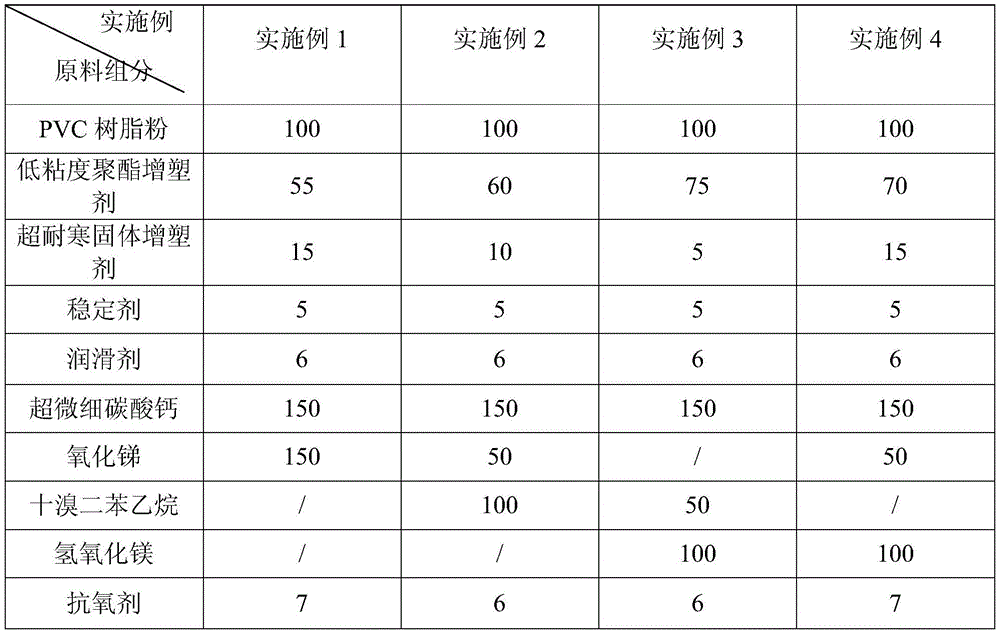

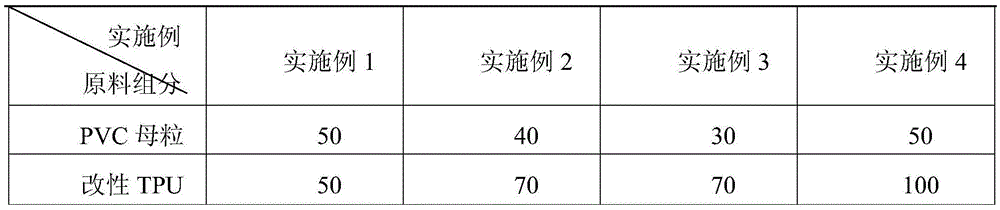

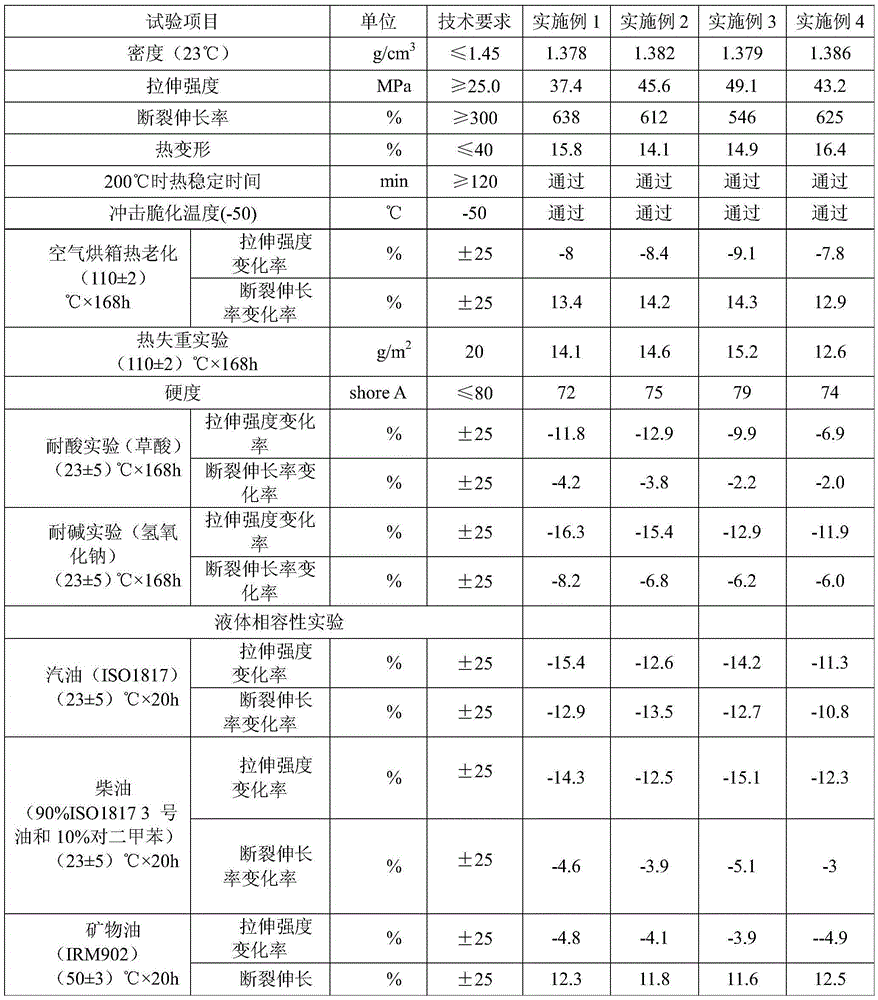

[0034] This embodiment provides a PVC / TPU oil-resistant flame-retardant thermoplastic elastomer material for new energy vehicle charging pile cables. The raw material formula is shown in Table 1 and Table 2. The specific raw materials used are:

[0035] Polyvinyl chloride (PVC) resin: a mixture of resin powder with a degree of polymerization of 800, 1300 and a degree of polymerization of 2500 in a weight ratio of 1:2:7;

[0036] Plasticizer: a mixture of low-viscosity polyester plasticizer and super cold-resistant solid plasticizer in a weight ratio of 11:3;

[0037] Stabilizer: calcium-zinc compound stabilizer (RUP151NB);

[0038] Lubricant: a mixture of stearic acid, calcium stearate, polyethylene wax, semi-refined paraffin wax in a weight ratio of 1:2:1.2:1.5;

[0039] Inorganic filler: 150 parts of ultrafine calcium carbonate (3000 mesh);

[0040] Flame retardant: antimony oxide;

[0041] Antioxidant: Antioxidant 1010;

[0042] The preparation method includes the following steps:

[004...

Embodiment 2

[0047] This embodiment provides a PVC / TPU oil-resistant flame-retardant thermoplastic elastomer material for new energy vehicle charging pile cables. The raw material formula is shown in Table 1 and Table 2. The specific raw materials used are:

[0048] Polyvinyl chloride (PVC) resin: a mixture of resin powder with a degree of polymerization of 800 and a degree of polymerization of 2500 in a weight ratio of 1:5;

[0049] Plasticizer: a mixture of low-viscosity polyester plasticizer and super cold-resistant solid plasticizer in a weight ratio of 6:1;

[0050] Stabilizer: calcium-zinc compound stabilizer (RUP144)

[0051] Lubricant: a mixture of stearic acid, calcium stearate, polyethylene wax, ACR401 in a weight ratio of 1:2::1.2:1.5;

[0052] Inorganic filler: 150 parts of superfine calcium carbonate (2500 mesh);

[0053] Flame retardant: a mixture of antimony oxide and decabromodiphenylethane in a ratio of 1:2:

[0054] Antioxidant: Antioxidant DLTP

[0055] The preparation method is basi...

Embodiment 3

[0057] This embodiment provides a PVC / TPU oil-resistant flame-retardant thermoplastic elastomer material for new energy vehicle charging pile cables. The raw material formula is shown in Table 1 and Table 2. The specific raw materials used are:

[0058] Polyvinyl chloride (PVC) resin: a mixture of resin powder with a degree of polymerization of 800, 1300 and a degree of polymerization of 3000 in a weight ratio of 1:2:7;

[0059] Plasticizer: a mixture of low-viscosity polyester plasticizer and super cold-resistant solid plasticizer in a weight ratio of 15:1;

[0060] Stabilizer: calcium-zinc compound stabilizer (RUP144);

[0061] Lubricant: stearic acid, barium stearate, M-80, semi-refined paraffin wax in a weight ratio of 1:2:1.4:1.5 mixture;

[0062] Inorganic filler: 150 parts of ultrafine calcium carbonate (3000 mesh);

[0063] Flame retardant: mixture of decabromodiphenyl ethane and magnesium hydroxide in a weight ratio of 1:2;

[0064] Antioxidant: Antioxidant 1010 and antioxidant D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com