Preparation method and application of polypyrrole/graphene/bacterial cellulose conducting film material

A bacterial cellulose and graphene technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of conductive film materials not having stability, cycle performance and mechanical properties, corrosion of conductive film materials themselves and instruments and other problems, to achieve the effect of good biodegradability, high crystallinity and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

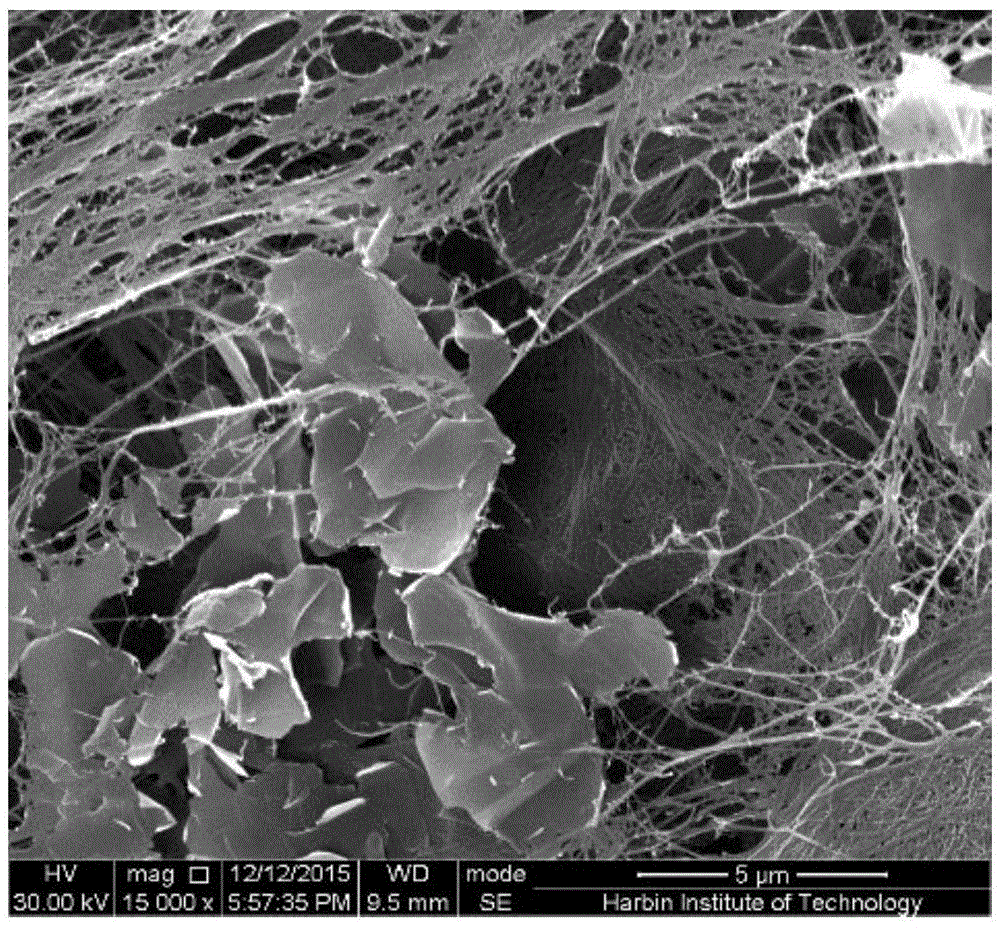

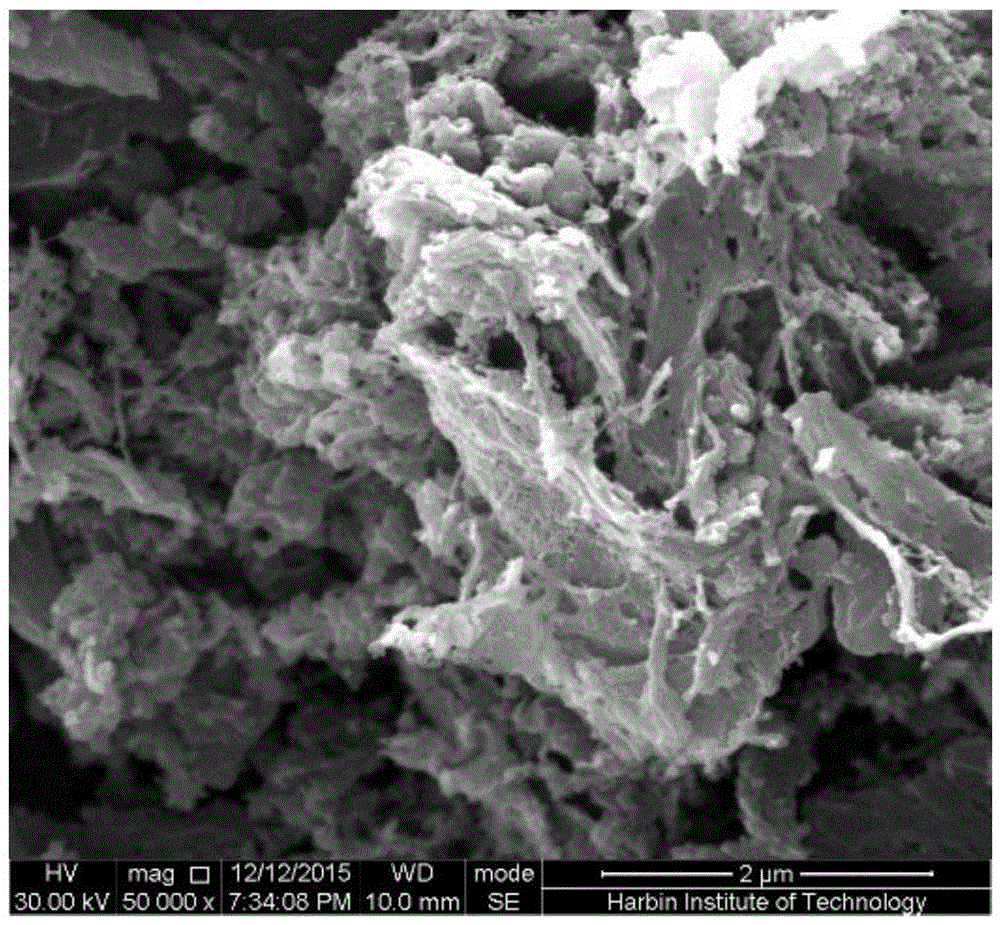

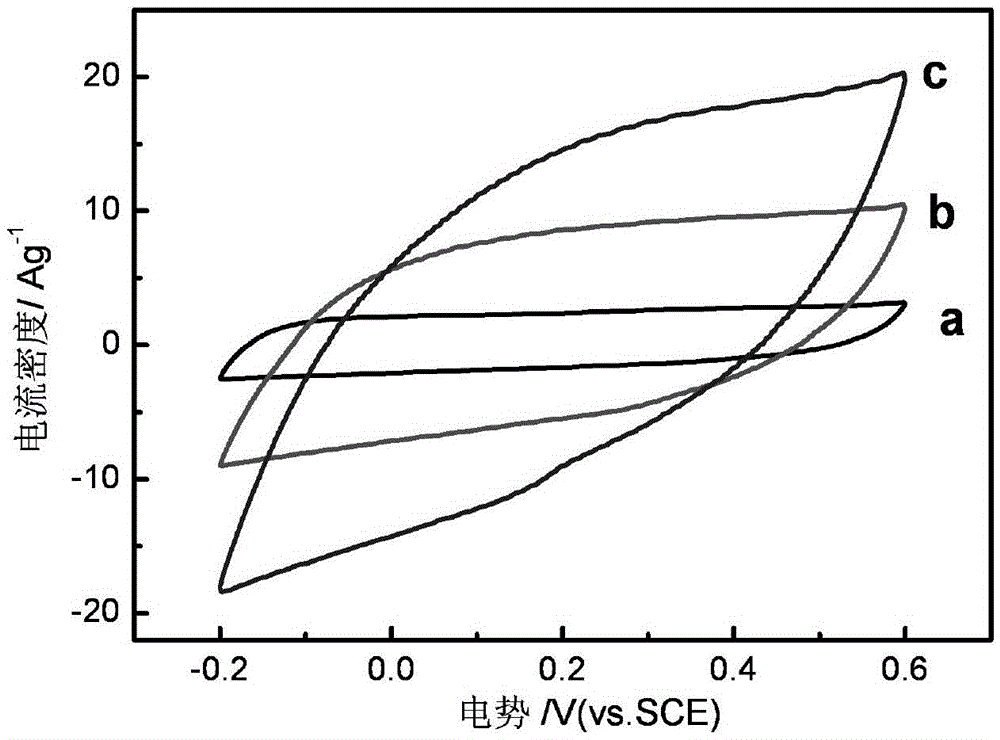

[0024] Specific embodiment one: the preparation method of a kind of polypyrrole / graphene / bacterial cellulose conductive membrane material of this embodiment is carried out according to the following steps:

[0025] 1. Soak the bacterial cellulose in deionized water and ultrasonically wash it, then evenly disperse it in deionized water, and then transfer it to a homogenizer for high-speed stirring to obtain a bacterial cellulose slurry; disperse graphene and surfactants ultrasonically in In deionized water, a graphene dispersion is obtained; the graphene dispersion is added to the bacterial cellulose slurry, and stirred while adding, to obtain a mixed solution A;

[0026] 2. Disperse the pyrrole monomer in deionized water, then add the mixed solution A, and stir while adding, to obtain the mixed solution B;

[0027] 3. Dissolve ammonium persulfate in deionized water to obtain an ammonium persulfate solution; add the ammonium persulfate solution to the mixed solution B, in-situ ...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that: the power of the ultrasound is 1000w, and the frequency is 30KHZ. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that: the condition of the ultrasonic washing described in step 1 is the ultrasonic time of 1-10 hours. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com