Preparation of silicon dioxide/titanium dioxide composite aerogel for lithium battery negative electrode material

A technology of composite aerogel and silica, used in battery electrodes, negative electrodes, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

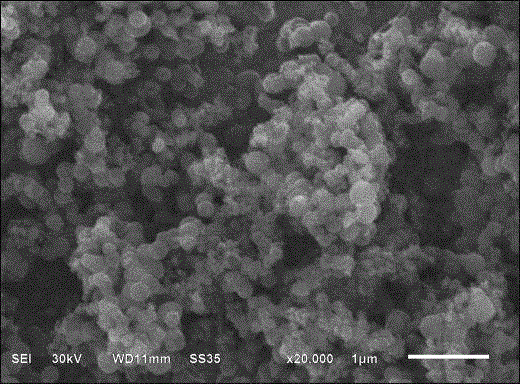

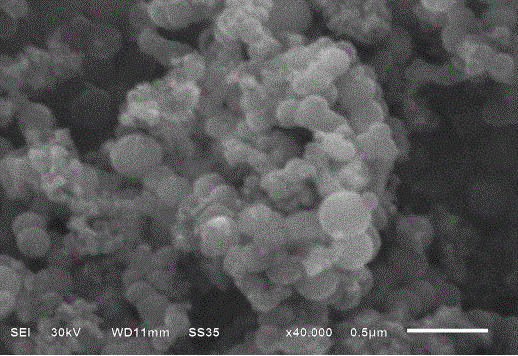

Image

Examples

Embodiment 1

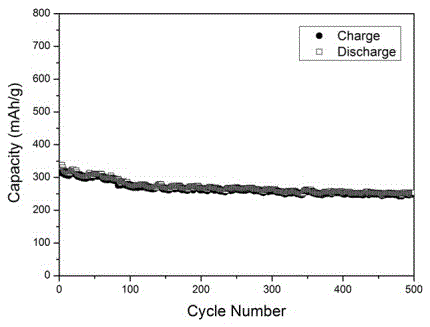

[0016] Mix ethyl orthosilicate, n-butyl titanate, ethanol and aqueous solution with a magnetic stirrer at a volume ratio of 1:1:8.0:3.5, and adjust the pH value with 1mol / L hydrochloric acid to obtain a completely clear and transparent precursor The aqueous solution of ammonia is slowly added dropwise to the above-mentioned precursor solution, and the pH value is controlled to be 8.2 to obtain a silica / titania composite hydrosol; the obtained silica / titania composite hydrosol is poured into a beaker and placed in a closed desiccator for condensation Gel, after gel formation in 20 0 Aging at C for 4 days, soak the aged gel in n-hexane, replace the n-hexane 3 times within 48 hours, remove the liquid, and then dry the sample with supercritical fluid to obtain the mass ratio of silicon dioxide and titanium dioxide It is a 1:1 silica / titania composite airgel. Accurately weigh 0.3168g of silica / titania composite airgel, 0.0495g of acetylene black and Polyvinylidene fluoride 0.0464...

Embodiment 2

[0018] Mix ethyl orthosilicate, n-butyl titanate, solvent ethanol and aqueous solution with a magnetic stirrer at a volume ratio of 1:0.5:8.0:3.5, and adjust the pH value with 1mol / L hydrochloric acid to obtain a completely clear and transparent Precursor solution; slowly add ammonia solution dropwise to the above precursor solution, and control the pH value to 7-11 to obtain a silica / titania composite hydrosol; the obtained silica / titania composite hydrosol is poured into a beaker and placed in an airtight dry Gel in the container, after the gel is formed, it will take 5-30 0Aging at C temperature for 3-4 days, soak the aged gel in n-hexane, replace the n-hexane 3 times within 48 hours, remove the liquid, and then dry the sample with supercritical fluid to obtain silicon dioxide and titanium dioxide Silica / titania composite airgel with a mass ratio of 2:1. Accurately weigh 0.3168g of silica / titania composite airgel, 0.0495g of acetylene black and Polyvinylidene fluoride 0.0...

Embodiment 3

[0020] Mix tetraethyl orthosilicate, solvent ethanol, and aqueous solution under magnetic stirrer stirring at a volume ratio of 1:8.0:3.5, and adjust the pH value by 1mol / L hydrochloric acid to obtain a completely clear and transparent precursor solution; Add it dropwise to the above precursor solution, and control the pH value to 7-11 to obtain a silica hydrosol; pour the obtained silica hydrosol into a beaker and place it in a closed desiccator to gel. 0 Aging at C for 3 days, soaking the aged gel in n-hexane, replacing the n-hexane three times within 48 hours, removing the liquid, and then drying the sample with supercritical fluid to obtain silica aerogel. Take tetrabutyl titanate, ethanol and deionized water at a volume ratio of 1:10:2, mix them evenly under constant stirring, then add an appropriate amount of silica airgel to it and continue stirring, Until the airgel was completely dissolved in the mixed solution, the mixture was left to stand at room temperature for 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com