Marine compound protein powder containing oyster peptide and preparation method of marine compound protein powder containing oyster peptide

A technology of compounding protein powder and oyster peptide, applied in the food field, can solve the problems of products such as oyster protein peptide that have not been queried, and achieve the effects of increasing the content of choline acetate in brain cells, improving memory, and scientifically and reasonably proportioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1, the preparation method of marine composite protein powder of the present invention comprises the following steps:

[0047] (1) Take each component by weight percentage as follows (before all raw material components are packaged, carry out quality inspection respectively to ensure that each component reaches the quality standard):

[0048] Soy protein isolate: 60-80 parts;

[0049] Whey protein: 8-20 servings;

[0050] Peanut protein: 2 to 5 parts;

[0051] Oyster peptide: 1 to 5 parts;

[0052] Maltodextrin: 3 to 6 parts;

[0053] Fructose-oligosaccharide: 0-16 parts;

[0054] Soy lecithin: 0.3-0.6 parts;

[0055] L-calcium lactate: 0-1.2 parts;

[0056] Zinc lactate: 0-0.05 parts;

[0057] Taurine: 0-0.15 parts;

[0058] Silicon dioxide: 0.3 to 0.7 parts;

[0059] (2) Put the above-mentioned raw materials into an automatic mixer and mix them for 10-15 minutes to obtain a uniform mixture;

[0060] (3) Put the homogeneous mixture into a fluidized bed for gra...

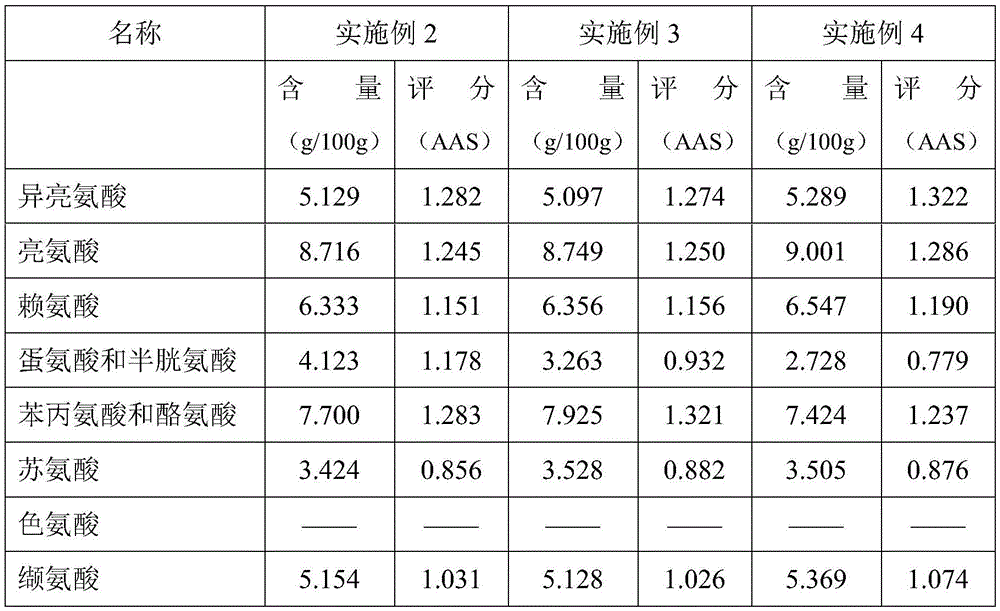

Embodiment 2

[0069] The preparation method of marine composite protein powder described in this embodiment comprises the following steps:

[0070] (1) Accurately weigh each component by the following weight percentage:

[0071] Soy protein isolate: 75 servings;

[0072] Whey protein: 14 servings;

[0073] Peanut protein: 3.5 parts;

[0074] Oyster peptide: 2.0 parts;

[0075] Maltodextrin: 4.6 parts;

[0076] Soy lecithin: 0.5 parts;

[0077] Silicon dioxide: 0.4 parts;

[0078] (2) Put the above-mentioned raw materials into an automatic mixer and mix them for 10-15 minutes to obtain a uniform mixture;

[0079] (3) Put the homogeneous mixture into a fluidized bed for granulation. The granulation conditions are: use 50% ethanol aqueous solution by volume, the material temperature is 45°C, the inlet air temperature is 85°C, the wind speed is 650rpm, and the peristaltic pump speed 6.59g / min;

[0080] (4) Packaging after sterilization and testing.

Embodiment 3

[0082] The preparation method of marine composite protein powder described in this embodiment comprises the following steps:

[0083] (1) Accurately weigh each component by the following weight percentage:

[0084] Soy protein isolate: 62 servings;

[0085] Whey protein: 10.85 servings;

[0086] Peanut protein: 3.1 parts;

[0087] Oyster peptide: 1.55 parts;

[0088] Maltodextrin: 5 parts;

[0089] Soy lecithin: 0.5 parts;

[0090] Silicon dioxide: 0.4 part;

[0091] Fructose-oligosaccharide: 15.8 parts;

[0092] L-calcium lactate: 0.8 parts;

[0093] (2) Put the above-mentioned raw materials into an automatic mixer and mix them for 10-15 minutes to obtain a uniform mixture;

[0094] (3) Put the homogeneous mixture into a fluidized bed for granulation. The granulation conditions are as follows: use an aqueous ethanol solution with a volume ratio of 60%, the material temperature is 40°C, the inlet air temperature is 90°C, the wind speed is 700rpm, and the peristaltic pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com