A kind of method for preparing silica sol

A technology of silica sol and inorganic acid, which is applied in the chemical industry, can solve the problems of large waste water, high energy consumption, and long process, and achieve the effect of less impurities, high silicon content, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

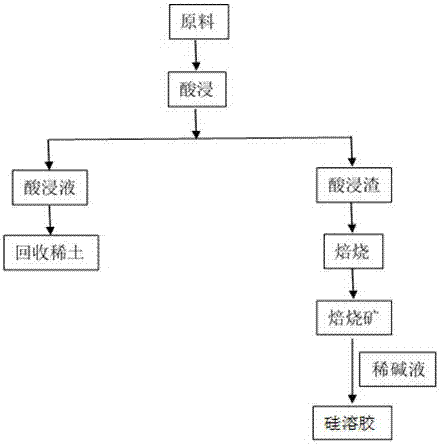

Method used

Image

Examples

Embodiment 1

[0013] Take 50g of Baiyun Obo mine tailings, leaching with 360ml, 2N hydrochloric acid at a temperature of 80°C for 3 hours to obtain acid leaching solution and acid leaching residue, then roasting in a muffle furnace at 800°C for 5 hours, cooling and taking out to obtain roasted ore, Under the regulation of ethyl acetate, the roasted ore was slowly added to 300ml, 5at% sodium hydroxide solution, and reacted at 60°C for 5h to obtain silica sol. The recovery rate of silicon was 90%, and SiO 2 The content is 30 at %.

Embodiment 2

[0015] Take 50g of Baiyun Obo tailings, leaching with 360ml, 2N hydrochloric acid at a temperature of 80°C for 3h to obtain acid leaching slag, then roast in a muffle furnace at 600°C for 5h, cool and take it out to obtain roasted ore, and roast ore in the The roasted ore was slowly added to 150ml of 10 at % sodium hydroxide solution under the regulation of ethyl acetate, and reacted at 70°C for 5 hours to obtain silica sol, the recovery rate of silicon was 92%, and the SiO 2 The content is 25 at %.

Embodiment 3

[0017] Take 50g of Baiyun Obo tailings, leaching with 500ml, 2N hydrochloric acid at a temperature of 80°C for 3h to obtain acid leaching slag, then roast in a muffle furnace at 800°C for 5h, cool and take it out to obtain roasted ore, under the adjustment of sulfuric acid , slowly added to 100ml, 15at % sodium hydroxide solution, reacted at 90°C for 3h to obtain silica sol, the recovery rate of silicon was 97%, SiO 2 The content is 24 at%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com