A kind of aminated high specific surface area polystyrene resin and its preparation method and application

A technology of polystyrene resin and styrene resin, which is applied in the field of cigarette harm reduction additive materials, can solve the problems of decreased specific surface of resin, difficult to carry out functionalization reaction, etc., and achieves the effects of improving efficiency, good adsorption effect, and efficient removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

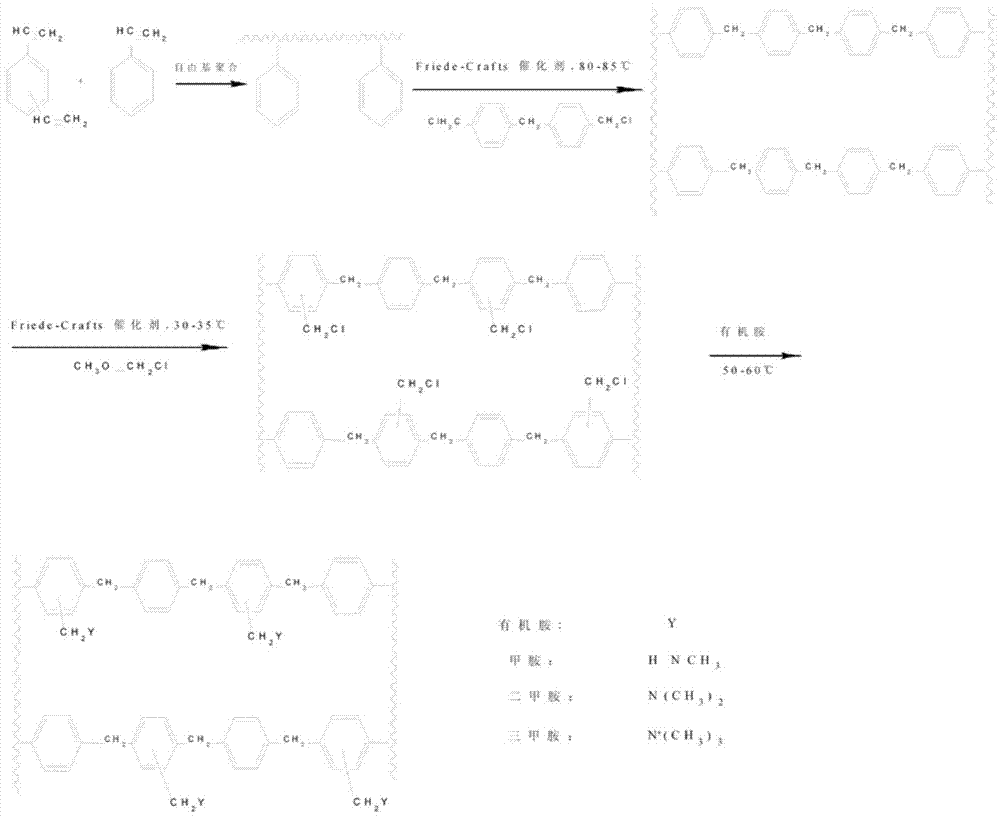

[0037] The preparation method of above-mentioned aminated high specific surface area polystyrene resin comprises the steps:

[0038] Step 1, prepare polystyrene resin (also known as white ball);

[0039] Step 2, preparing ultra-high cross-linked polystyrene resin;

[0040] Step 3, preparing chloromethylated ultra-high cross-linked polystyrene resin (also known as chlorine ball);

[0041] Step 4, preparing aminated high specific surface area polystyrene resin.

[0042] Wherein, the above step one includes:

[0043] (1a) a step of preparing an aqueous phase;

[0044] The polyvinyl alcohol is dissolved in water to form a suspension polymerized water phase, so that the concentration of the polyvinyl alcohol in the water phase reaches 0.5-2 wt%, and then the water phase is placed in a three-necked flask and heated to 30-50°C.

[0045] In this step, the purpose of heating the water phase is to promote the dissolution of polyvinyl alcohol in water.

[0046] (1b) the step of prep...

Embodiment 1

[0069] (1) Preparation of polystyrene resin (white ball):

[0070] Dissolve 15 g of polyvinyl alcohol in 1500 g of water in a three-necked flask with a capacity of 3 L (that is, the concentration of polyvinyl alcohol is 1 wt %) to obtain a suspension-polymerized water phase, which is heated to 40° C.

[0071] In addition, after mixing 99g of divinylbenzene (DVB, purity 55.3wt%), 198g of toluene, and 0.495g of azobisisobutyronitrile (AIBN), they were added to the above-mentioned three-necked flask to obtain the oil phase of suspension polymerization (i.e., toluene The mass ratio with DVB is 2:1, and AIBN accounts for 0.5% of divinylbenzene mass).

[0072] Add the suspension polymerized oil phase to the above water phase at a mass ratio of 1:5, start stirring, and at the same time raise the temperature of the reaction system to 76°C for 4 hours, then raise the temperature to 85°C, stop the reaction after 4 hours, and filter to obtain Spherical resin particles, washed and dried ...

Embodiment 2

[0081] (1) Preparation of polystyrene resin:

[0082] In a three-necked flask with a capacity of 3 L, 6.9 g of polyvinyl alcohol was dissolved in 1350 g of water (the concentration of polyvinyl alcohol was 0.5 wt %) to obtain a suspension polymerized water phase, which was heated to 35° C.

[0083] In addition, after mixing 112.5g divinylbenzene (DVB, purity 65.6wt%), 337.5g toluene, and 1.125g azobisisobutyronitrile (AIBN), they were added to the above-mentioned three-necked flask to obtain the oil phase of suspension polymerization ( That is, the mass ratio of toluene and DVB is 3:1, and AIBN accounts for 1% of the monomer mass);

[0084] Add the suspension polymerized oil phase to the above water phase at a mass ratio of 1:3, start stirring, and at the same time raise the temperature of the reaction system to 78°C for 2 hours, then raise the temperature to 90°C, and stop the reaction after 6 hours of reaction, filter and wash and dry to obtain polystyrene resin.

[0085] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com