Production method for high-purity chromium metal and vacuum arc furnace adopted by production method

A technology of a vacuum electric arc furnace and a production method, applied in the field of electric arc furnaces, can solve the problems of small production capacity, low efficiency, extremely difficult to produce products, etc., and achieve high production efficiency, low production cost, and reduced energy consumption and production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

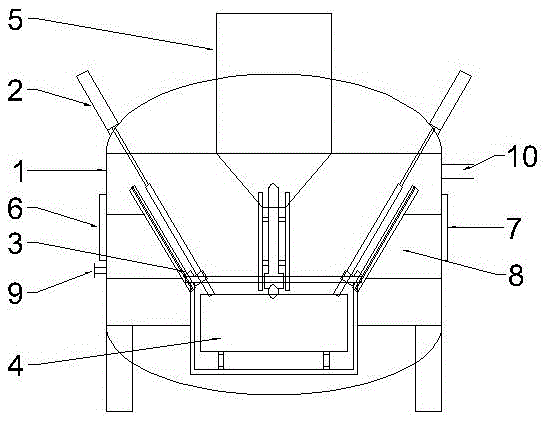

[0029] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 , a kind of production method of high-purity metallic chromium described in the present embodiment comprises the following steps:

[0030] 1) 100-120 parts of chromium trioxide with a content of 99%, 24-35 parts of carbon powder with a fixed carbon content of more than 95%, and 1-20 parts of a binder according to the weight ratio;

[0031] 2) According to the weight ratio, put the above ingredients into a dry powder mixer and stir for 30~40min to make a mixed raw material and set aside;

[0032] 3) Put the fully mixed raw materials into the compactor to make billets;

[0033] 4) Put the briquette into the material bin of the vacuum electric arc furnace, open the furnace door, start the arc first, and close the furnace door after the current temperature is reached, draw the vacuum to 100~110 Pa, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com