FeP/graphene composite material and preparation method thereof

A composite material and graphene technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as difficult effective control and long process, and achieve the effect of regular structure, easy scale-up production, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of FeP / graphene composite material, comprises the following steps,

[0027] (a) Add melamine, glucose and ferric chloride in a molar ratio of 20:1:0.001 into deionized water at 95°C, and stir until completely dissolved to obtain a mixed solution;

[0028] (b) Add phosphoric acid to the mixed solution described in step (a), the molar ratio of phosphate and melamine is 1:1, stir until evenly mixed, and then dry by rotary evaporation to obtain melamine phosphate precipitation;

[0029] (c) In a tube furnace, under the protection of nitrogen, the temperature was raised to 600°C at 5°C / min, and kept for 2 hours, then raised to 900°C at 5°C / min, kept for 2 hours, and taken out after cooling to obtain FeP / Graphene composites.

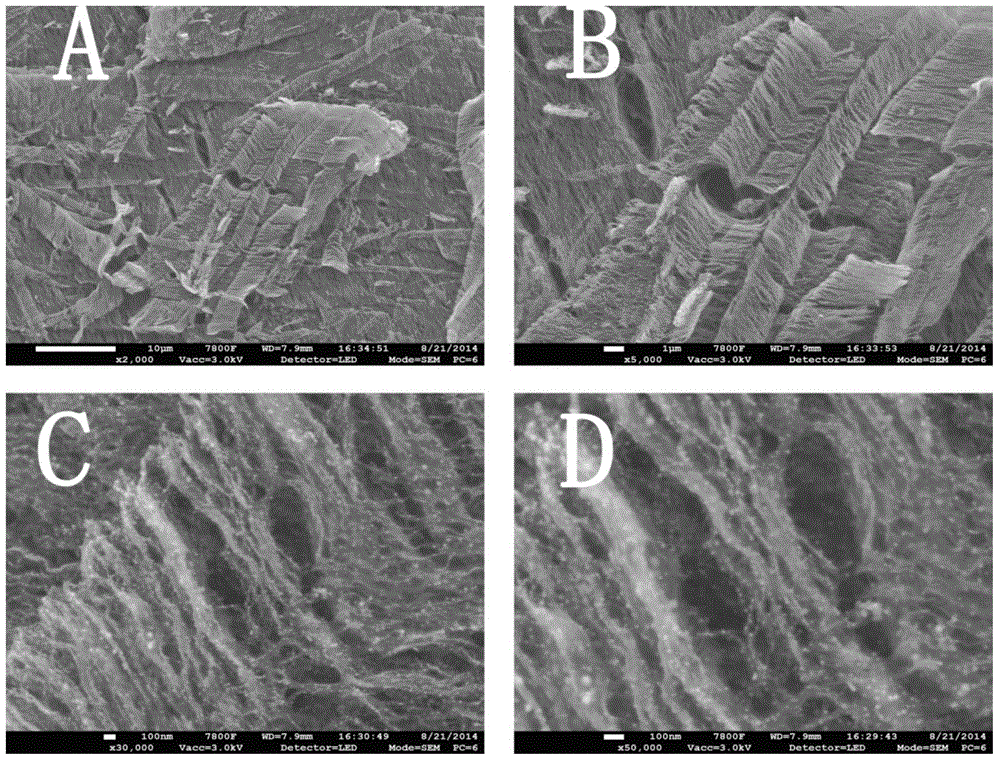

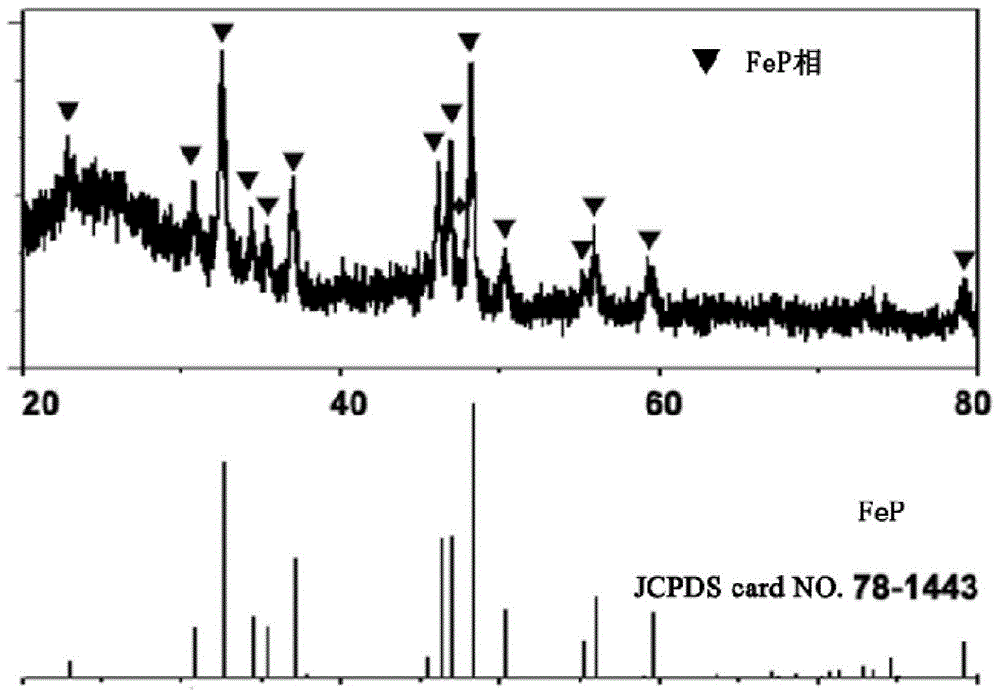

[0030] From figure 1 It can be seen that the obtained material is very regular and consists of neatly arranged exfoliated lamellar material ( figure 1 A)( figure 1 B). The thickness of these exfoliated sheets is about ...

Embodiment 2

[0034] A kind of preparation method of FeP / graphene composite material, comprises the following steps,

[0035] (a) Add melamine, glucose and ferric chloride in a molar ratio of 10:1:0.001 into deionized water at 95°C, and stir until completely dissolved to obtain a mixed solution;

[0036] (b) Add concentrated (35%) phosphoric acid to the mixed solution described in step (a), the molar ratio of phosphate and melamine is 4:5, stir until evenly mixed, then rotary evaporate and dry to obtain melamine phosphate precipitation;

[0037] (c) In a tube furnace, under the protection of nitrogen, the temperature was raised to 550°C at 5°C / min, kept for 2 hours, then raised to 950°C at 5°C / min, kept for 2 hours, and taken out after cooling to obtain FeP / Graphene composites.

[0038] The number of layers of graphene in the FeP / graphene composite material obtained in this embodiment is between 5-10 layers, the nanoparticles are FeP and carbon-coated FeP, the loading of nanoparticles is ...

Embodiment 3

[0040] A kind of preparation method of FeP / graphene composite material, comprises the following steps,

[0041] (a) Add melamine, glucose and ferric chloride with a molar ratio of 8:1:0.002 into deionized water at 95°C, and stir until completely dissolved to obtain a mixed solution;

[0042] (b) Add concentrated (35%) phosphoric acid to the mixed solution described in step (a), the molar ratio of phosphate and melamine is 2:1, stir until evenly mixed and then dry by rotary evaporation to obtain melamine phosphate precipitation;

[0043] (c) In a tube furnace, under the protection of argon, raise the temperature to 600°C at 10°C / min, keep it for 2 hours, then raise the temperature to 1000°C at 20°C / min, keep it for 10 hours, and take it out after cooling to get FeP / graphene composites.

[0044] The number of layers of graphene in the FeP / graphene composite material obtained in this embodiment is between 10-20 layers, the nanoparticles are FeP and carbon-coated FeP, the loadi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com