Core-shell structured carbon/sulfur composite positive electrode material, preparation method and application therefor

A technology of composite cathode material and core-shell structure, applied in the field of electrochemistry, can solve the problems of high production cost, low sulfur loading, poor stability, etc., and achieve the effects of improving utilization rate, solving volume expansion, and being environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

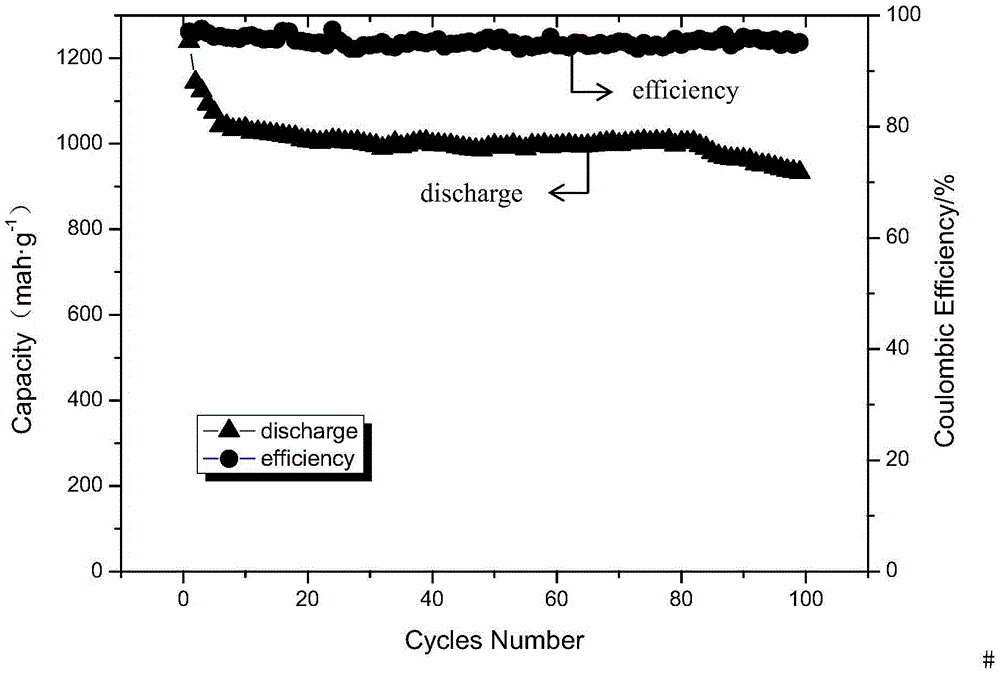

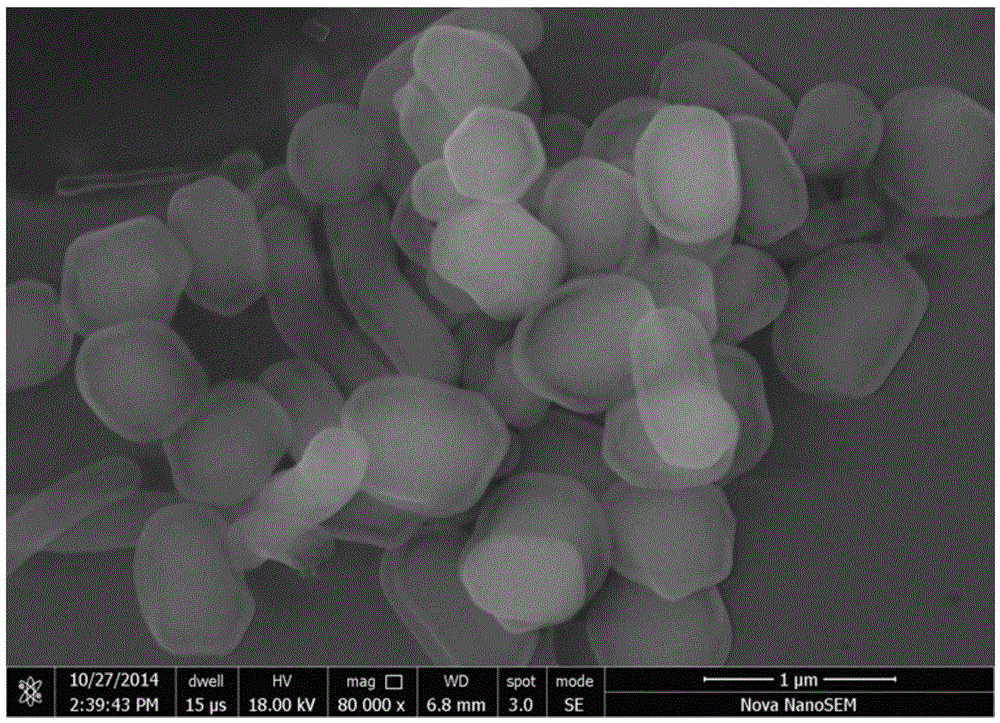

[0026] The positive electrode material of lithium-sulfur battery with porous core-shell structure in the shell wall of this embodiment has an average pore diameter of 9.28nm and a pore volume of 0.709cm 3 / g.

[0027] The preparation method of the lithium-sulfur battery cathode material of this example, the specific steps are:

[0028] (1) Add 1.5ml of ammonia water, 60ml of ethanol, 150ml of deionized water, 1.5g of resorcinol, and 1.5g of CTAB into a round bottom flask and stir for 30min. Then 7.5ml TEOS and 2.1ml formaldehyde were added, stirred at 25°C for 24h, and then stood in an oil bath at 100°C for 24h. The reaction product was obtained by suction filtration, dried in a thermostat at 60°C for 8 hours, and dried in a tube furnace for N 2 Carburize at 700°C for 3 hours in the atmosphere, with a heating rate of 2°C / min, and finally etch in 5mol / L NaOH at 80°C for 10 hours to remove SiO 2 , after washing, suction filtration and drying, a porous core-shell structure car...

Embodiment 2

[0037] The preparation method of the lithium-sulfur cathode material in this embodiment, the specific steps are:

[0038](1) Add 0.15ml of ammonia water, 6ml of ethanol, 18ml of deionized water, 0.15g of resorcinol, and 0.15g of sodium dodecylsulfonate into a round bottom flask and stir for 30min. Then add 0.75ml TEOS and 0.21ml formaldehyde, stir at 25°C for 24h, then stand in an oil bath at 100°C for 24h. The reaction product was obtained by suction filtration, dried in a thermostat at 60°C for 8 hours, and dried in a tube furnace for N 2 Carburize at 600°C for 4 hours in the atmosphere, with a heating rate of 5°C / min, and finally etch in 8mol / L NaOH at 80°C for 10 hours to remove SiO 2 , after washing, suction filtration and drying, a porous core-shell structure carbon material with a shell wall is obtained.

[0039] (2) Put 0.15 g of the prepared carbon material and 0.15 g of sublimed sulfur into an agate ball mill jar, control the rotational speed of the planetary ball ...

Embodiment 3

[0047] The preparation method of the lithium-sulfur cathode material in this embodiment, the specific steps are:

[0048] (1) Add 0.3ml of ammonia water, 12ml of ethanol, 30ml of deionized water, 0.3g of resorcinol, and 0.6g of TX-100 into a round bottom flask and stir for 30min. Then 1.5ml TEOS and 0.42ml formaldehyde were added, stirred at 25°C for 24h, and then stood in an oil bath at 100°C for 24h. The reaction product was obtained by suction filtration, dried in a thermostat at 60°C for 8 hours, and dried in a tube furnace for N 2 Carburize at 500°C for 8h in the atmosphere, the heating rate is 3°C / min, and finally etch in 8mol / L NaOH at 80°C for 10h to remove SiO 2 , after washing, suction filtration and drying, a porous core-shell structure carbon material with a shell wall is obtained.

[0049] (2) Put 0.15 g of the prepared carbon material and 0.2 g of sublimed sulfur into an agate ball mill jar, control the rotational speed of the planetary ball mill to 500 r / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com