3D network pore structure super-capacitor carbon and preparation method thereof

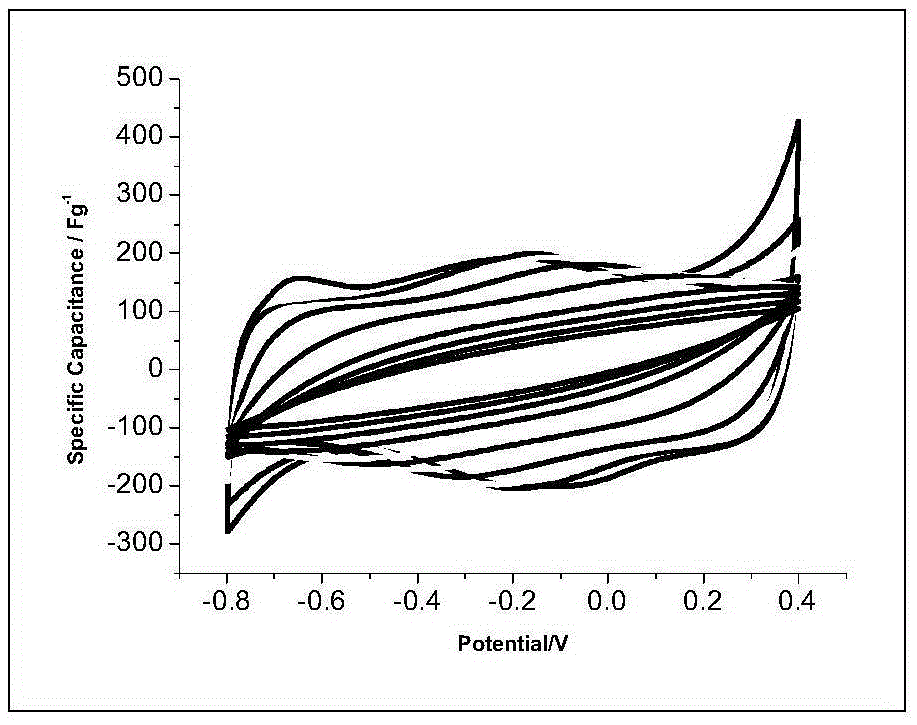

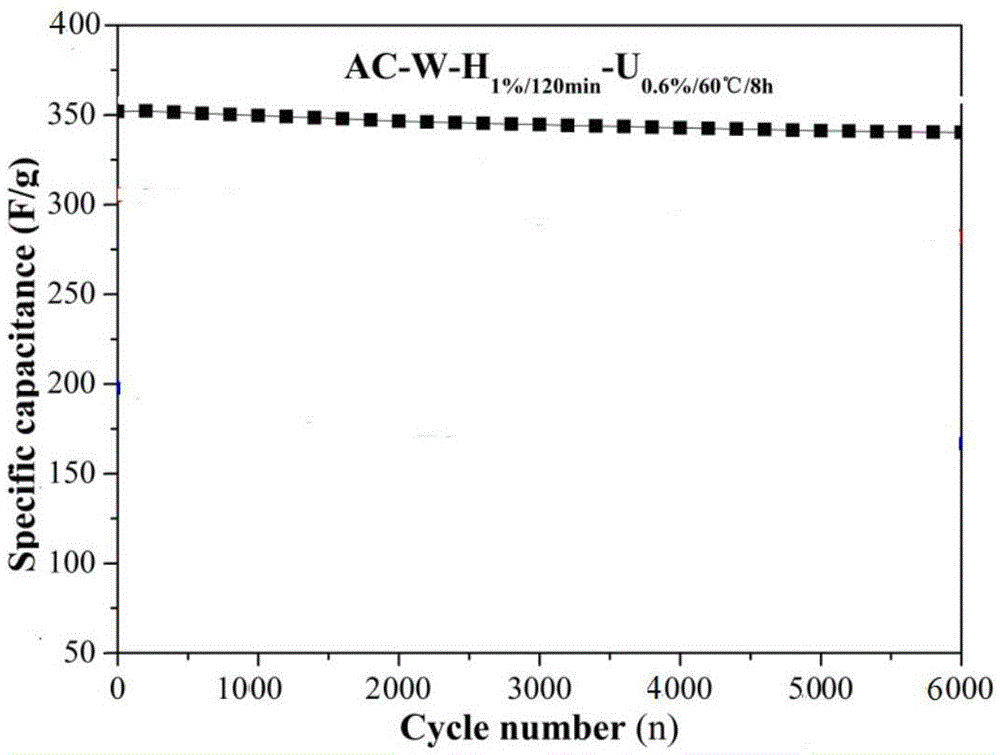

A supercapacitor and pore structure technology, applied in chemical instruments and methods, hybrid capacitor electrodes, inorganic chemistry, etc., can solve the problems of high cost, short service life, slow charging and discharging speed of supercapacitors, etc., achieve small internal resistance, improve The effect of charging and discharging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

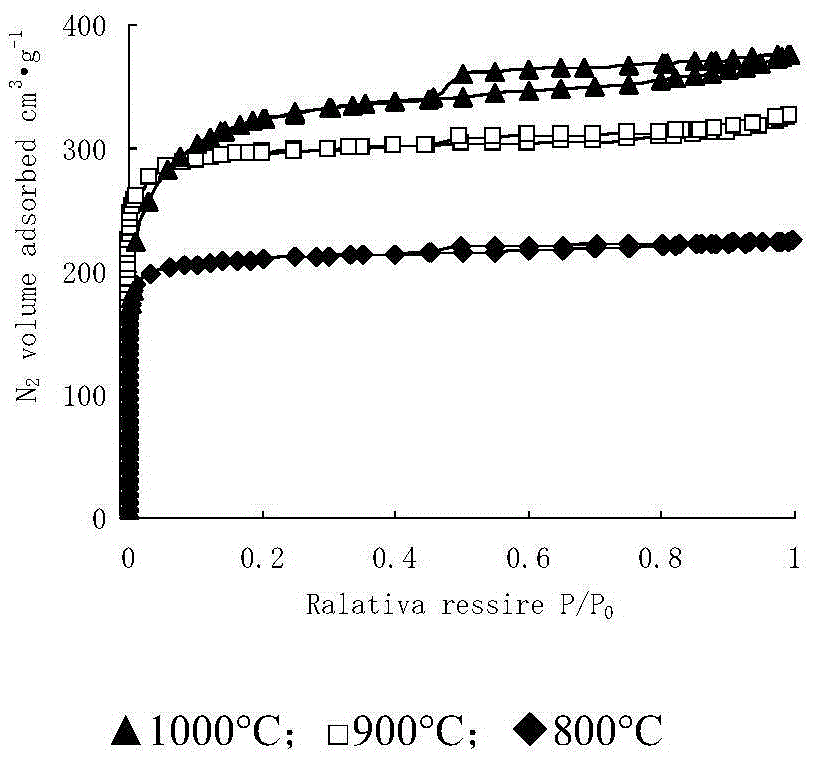

[0040] A preparation method of supercapacitor carbon with 3D network pore structure, using a new comprehensive activation method, first using ZnCl 2 Activation prepares well-developed medium and large pores, and then KOH is used to create abundant micropores in the medium and large pores, and the pores are connected; finally, it is refined with high-temperature steam to open the closed pores and remove the residual carbon particles in the pores. Obtain a 3D network pore structure interconnected inside, significantly reduce the resistance of electrolyte ions in and out, increase the charge and discharge speed, and reduce the capacitance decay rate. Specifically include the following steps:

[0041] The first step, raw material preparation: wash coconut shells, walnut shells, wood chips, bamboo chips, and straw with hydrochloric acid in stages to remove inorganic impurities, and after drying, crush them to less than 2mm;

[0042] The second step, ZnCl 2 Activation: configure z...

Embodiment 1

[0048] (1) Raw material preparation: the coconut shell is washed with 0.1mol / L hydrochloric acid in stages to remove inorganic impurities, and after drying, it is broken to less than 2mm;

[0049] (2) ZnCl 2 Activation: Zinc chloride is configured into an aqueous solution with a mass concentration of 60%. According to the mass ratio of 1:1, the coconut shell and the zinc chloride aqueous solution are mixed, placed in a closed high-pressure container, and immersed in a gas pressure of 0.5Mpa for 24 hours. After drying at 150°C, place the mixture in an activation furnace and activate at 600°C for 1 hour. After cooling, wash with deionized water to recover ZnCl 2 , to obtain activated carbon (AC-Zn) with rich medium and large pores;

[0050] (3) KOH activation: According to the mass ratio of 1:1, AC-Zn and KOH powder were mixed and placed in a stainless steel tank. 2 Heating pretreatment under protection for 1h, heating temperature 600°C; activation reaction at 900°C for 1h, af...

Embodiment 2

[0054] (1) Raw material preparation: the coconut shell is washed with 0.1mol / L hydrochloric acid in stages to remove inorganic impurities, and after drying, it is broken to less than 2mm;

[0055] (2) ZnCl 2 Activation: Zinc chloride is configured into an aqueous solution with a mass concentration of 60%. According to the mass ratio of 1:1, the coconut shell and the zinc chloride aqueous solution are mixed, placed in a closed high-pressure container, and immersed in a gas pressure of 0.5Mpa for 24 hours. After drying at 150°C, place the mixture in an activation furnace and activate at 600°C for 1 hour. After cooling, wash with deionized water to recover ZnCl 2 , to obtain activated carbon (AC-Zn) with rich medium and large pores;

[0056] (3) KOH activation: According to the mass ratio of 1:1, AC-Zn and KOH powder were mixed and placed in a stainless steel tank. 2 Heating pretreatment under protection for 1h, heating temperature 600°C; activation reaction at 900°C for 1h, af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com