Synthesis method of phosphonate-group polysiloxane

A technology of polysiloxane-based synthesis method, which is applied in the field of organosilicon polymer synthesis, can solve the problems of polysiloxane-containing phosphate-based polysiloxane performance effects, limited research on synthesis methods, and restrictions on wide application, etc. The effect of high ester group content, controllable content and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

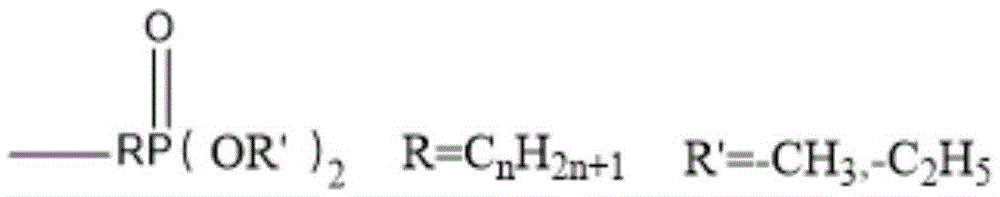

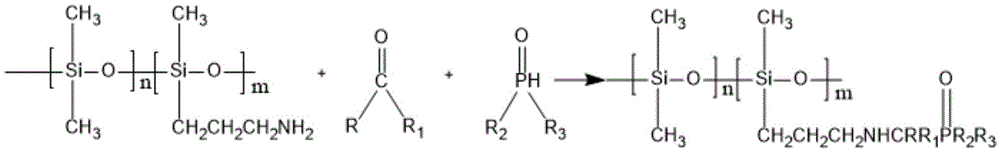

[0015] Technical scheme of the present invention is as follows:

[0016] A kind of synthetic method containing phosphonate group polysiloxane, comprises steps as follows:

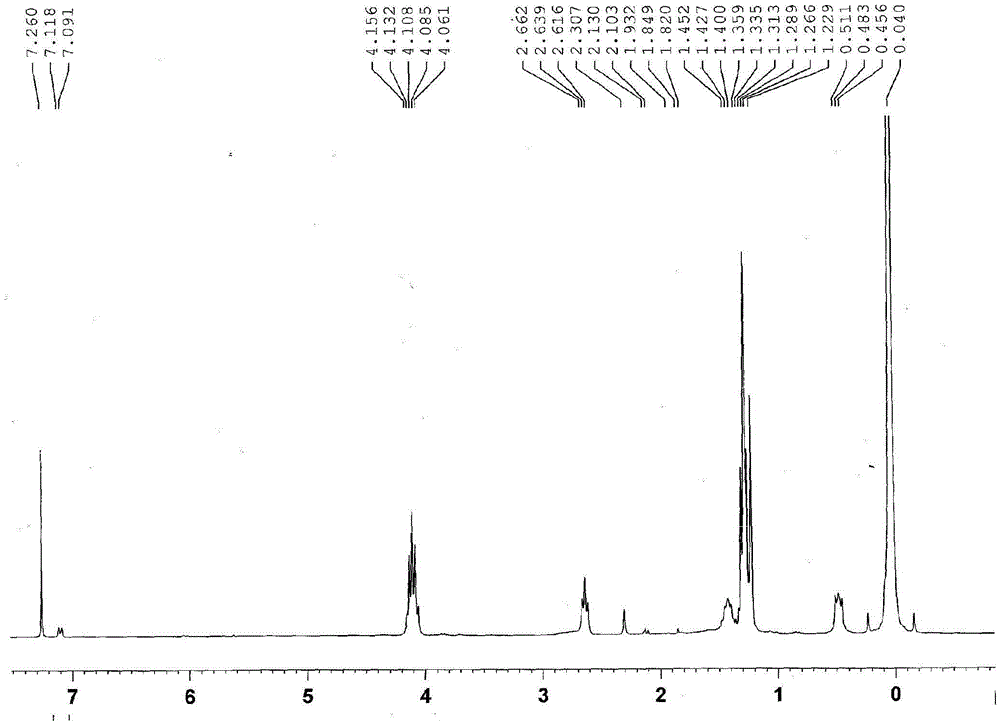

[0017] Under the condition of using solvent or not using solvent, mix polysiloxane containing amino group with alkyl phosphite and aldehyde and ketone compound, and introduce phosphine group into polysiloxane through Kabachnik-Fields reaction through catalyst Among the siloxane molecules, polysiloxanes containing phosphine groups are prepared.

[0018] The synthetic route of the present invention is as follows:

[0019]

[0020] Among them: n, m are integers.

[0021] According to the present invention, preferably, the molar ratio of polysiloxane containing amino groups, alkyl phosphite and aldehydes and ketones is 1: (1.5-2): (1.5-2);

[0022] Preferably, the reaction temperature is 20-30°C;

[0023] Preferably, the reaction time is 3-5 hours.

[0024] According to the present invention, preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com