Brewer's yeast engineering bacterium producing 2-phenylethyl alcohol, preparation method and applications thereof

A technology of Saccharomyces cerevisiae and engineering bacteria, applied in the field of genetic engineering, can solve the problems of limited 2-phenylethanol synthesis ability and difficulty in large-scale industrial production, and achieve the effects of improved synthesis ability, short fermentation cycle and simple fermentation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

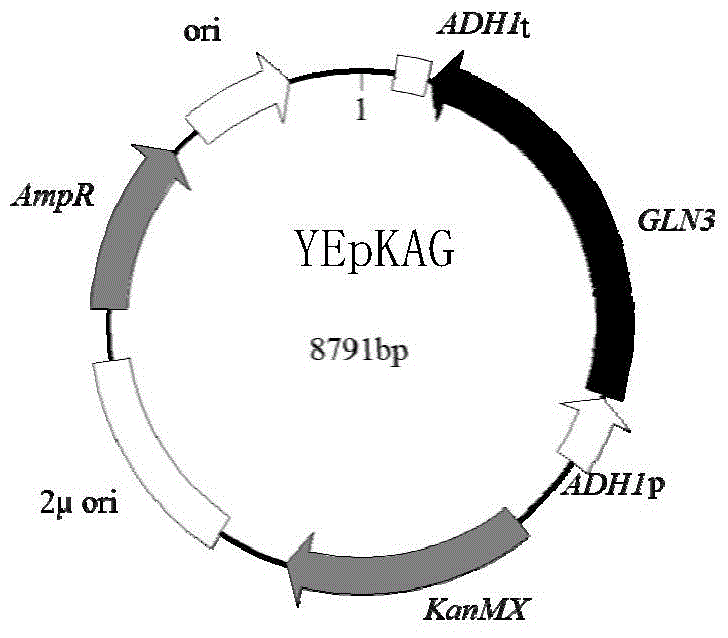

[0040] Embodiment 1, the construction of the Saccharomyces cerevisiae engineered bacteria that produces 2-phenylethanol

[0041] 1. Acquisition of GATA transcription factor Gln3p encoding gene GLN3

[0042] (1) PCR amplification of the gene GLN3 encoding the GATA transcription factor Gln3p

[0043] According to the GLN3 gene sequence (GenBank number is M35267) of the coding GATA transcription factor Gln3p of the reported Saccharomyces cerevisiae, design following primers:

[0044] Upstream primer P1: 5′-ACGC GTC GACAACAAATGCAAGACGACC-3' (SEQ ID No. 1)

[0045] (The underlined sequence is the SalI restriction recognition site)

[0046] Downstream primer P2: 5′-ACGC GAGCTC AATACGCGGTCATATACC-3' (SEQ ID No. 2)

[0047] (The underlined sequence is the SacI restriction recognition site)

[0048] (2) Using the genomic DNA of Saccharomyces cerevisiae MT2 with a higher yield of 2-phenylethanol as a template, and using P1 and P2 as primers to perform PCR amplification to obtain...

Embodiment 2

[0117] Embodiment 2, yeast fermentation method produces 2-phenylethanol

[0118] 1. Transfer the activated MT2 (YEpKAG), MT2 (YEpKA) and MT2 into a 250 mL Erlenmeyer flask containing 50 mL of fermentation medium, and culture on a shaker at 30°C and 220 rpm for 36 hours.

[0119] Above-mentioned fermentation medium is made up of solvent and solute, and solvent is water, and solute is L-phenylalanine, glucose, magnesium sulfate, potassium dihydrogen phosphate; The concentration of described L-phenylalanine in fermentation medium is 5g / L, the concentration of the glucose in the fermentation medium is 30g / L, the concentration of the magnesium sulfate in the fermentation medium is 0.5g / L, and the concentration of the potassium dihydrogen phosphate in the fermentation medium is 0.5 g / L.

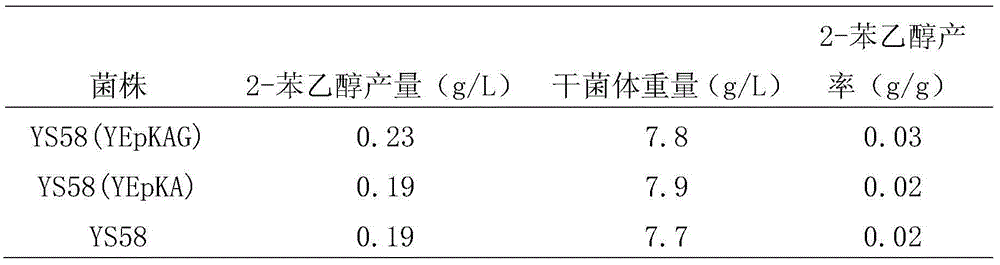

[0120] 2. After the fermentation finishes, take MT2 (YEpKAG), MT2 (YEpKA) and MT2 fermentation broth, centrifuge to get the supernatant, and measure the 2-phenylethanol output in the fermentation...

Embodiment 3

[0127] Embodiment 3, yeast fermentation method produces 2-phenylethanol

[0128] 1. Transfer the activated MT2 (YEpKAG), MT2 (YEpKA) and MT2 into a 250 mL Erlenmeyer flask containing 50 mL of fermentation medium, and culture on a shaker at 30°C and 220 rpm for 36 hours.

[0129] Above-mentioned fermentation medium is made up of solvent and solute, and solvent is water, and solute is L-phenylalanine, glucose, magnesium sulfate, potassium dihydrogen phosphate; The concentration of described L-phenylalanine in fermentation medium is 5g / L, the concentration of the glucose in the fermentation medium is 40g / L, the concentration of the magnesium sulfate in the fermentation medium is 0.5g / L, and the concentration of the potassium dihydrogen phosphate in the fermentation medium is 0.5 g / L.

[0130] 2. After the fermentation finishes, take MT2 (YEpKAG), MT2 (YEpKA) and MT2 fermentation broth, centrifuge to get the supernatant, and measure the 2-phenylethanol output in the fermentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com