Liquid conveying pipeline leakage and sewage blocking detection method based on frequency domain

A technology for conveying pipelines and detection methods, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of complex system hardware and software, slow detection speed, limited application, etc., to overcome sensitivity problems , Wide detection distance, easy miniaturization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0063] A detection method for leakage and fouling of a liquid delivery pipeline based on a frequency domain, the method is based on an active electric field liquid delivery pipeline internal detection device.

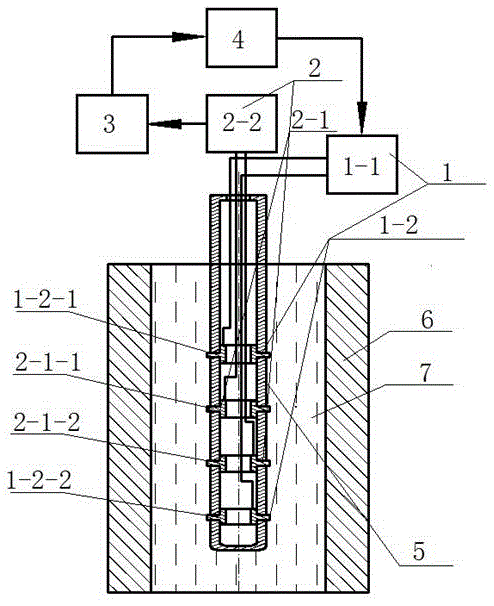

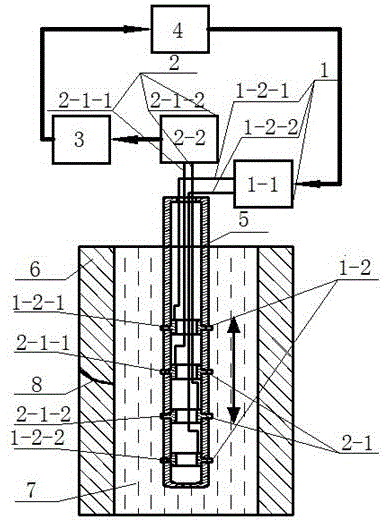

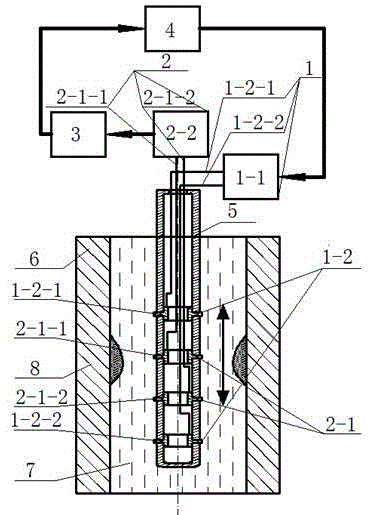

[0064] (1) Detection device in the active electric field liquid conveying pipeline

[0065] like figure 1 As shown, the internal detection device includes an active electric field emission device 1 , an electric field change detection device 2 , a data sampling device 3 , a data processor 4 and a probe holder 5 .

[0066] The active electric field emission device 1 includes a signal generator 1-1 and an emission electrode 1-2.

[0067] Further, the signal generator 1-1 is used to generate a sine wave signal within 2000HZ as an exci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com