Berberine nanocomposite and preparation method

A nano-composite, berberine technology, applied in the field of medicine and health, can solve the problems of affecting absorption, protein adsorption, limiting the use of berberine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

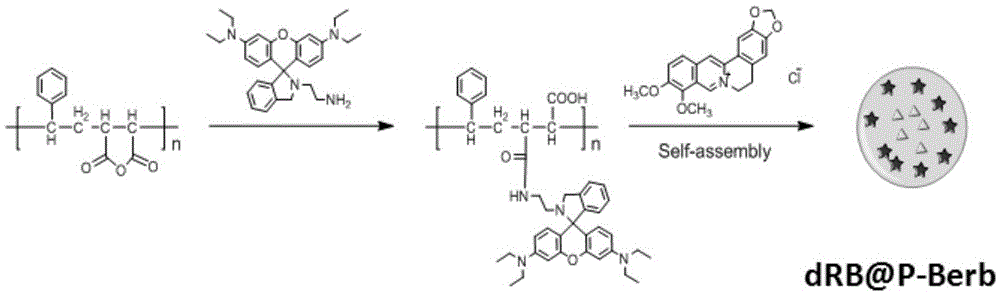

[0037] A kind of berberine nanocomposite, its preparation method is as follows:

[0038] At room temperature, dissolve 2 g of styrene-maleic anhydride alternating copolymer with a molecular weight of 20,000 in 10 ml of N,N-dimethylformamide and 1 ml of triethylamine, then add 500 mg of berberine hydrochloride or sulfuric acid salt, stirred overnight; add 5ml of saturated aqueous solution of sodium bicarbonate to remove acid anhydride, and stir again for 1h; use a dialysis bag with a molecular weight cut-off of 3500kD to remove substances with a molecular weight below 3500kD, freeze-dry or vacuum-dry, and dissolve the dried solid Prepare a 10 mg / ml solution in water, and ultrasonically treat it for 40 minutes to promote the self-assembly and formation of particles to obtain the berberine nanocomposite, which is a micro-beam structure.

Embodiment 2

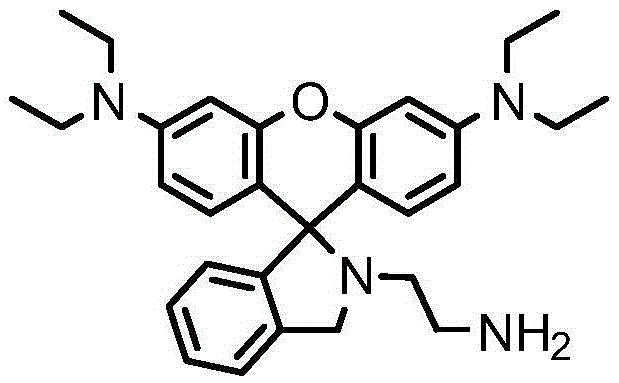

[0040] The difference between the berberine nanocomposite in this example and Example 1 is that rhodamine dRB is added as a marker, which is convenient for subsequent detection, but the addition of rhodamine dRB has an effect on the formation of berberine nanocomposite and The structure has no effect, and the specific preparation method is as follows:

[0041]At room temperature, 2 g of styrene-maleic anhydride alternating copolymers with a molecular weight of 20,000 were dissolved in 10 ml of N,N-dimethylformamide and 1 ml of triethylamine, and 1 ml of a concentration of 500 mg / N, N-dimethylformamide solution of dRB in ml, stirred for 2h; added 500mg of berberine hydrochloride, stirred overnight; added 5ml of saturated aqueous solution of sodium bicarbonate to remove acid anhydride, stirred again for 1h; After removing substances with a molecular weight below 3500kD for a dialysis bag of 3500kD, freeze-dry or vacuum-dry, dissolve the dried solid in water to make a 10mg / ml so...

experiment example 1

[0044] Experimental example 1 UV characterization

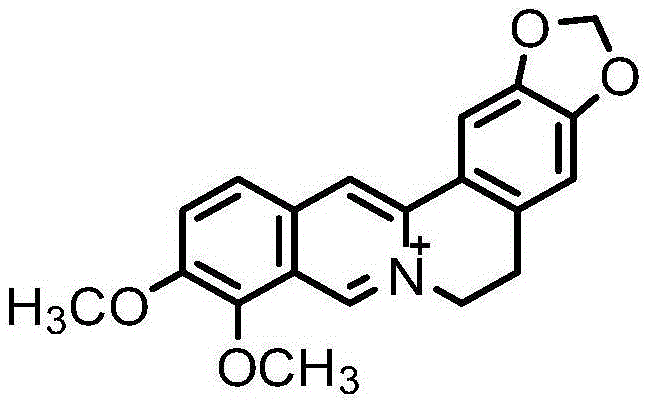

[0045] The solutions of berberine hydrochloride, the dRBP-Berb obtained in Example 2, and the dRBP obtained in Comparative Example 1 with a concentration of 100 μg / mL were prepared with PBS respectively; between UV absorption. The characteristic absorption peak of berberine is at λ=425nm, and the characteristic absorption peak of dRB is at λ=575nm.

[0046] The result is as Figure 4 Shown, berberine solution has maximum absorption peak at λ=425nm place, and the dRBP solution of comparative example 1 has maximum absorption peak at λ=575nm place; And the dRBP-Berb solution of embodiment 2 has maximum absorption peak at λ=425nm place and λ= There are absorption peaks at 575nm, indicating that the dRBP-Berb of Example 2 contains both berberine and dRB, that is, the dRBP-Berb of Example 2 was successfully prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com