Quantum dot photocatalytic flexible film as well as preparation method and application thereof

A flexible thin film and quantum dot technology, applied in the direction of chemical instruments and methods, applications, separation methods, etc., to achieve the effects of recycling resources, controlling emission, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

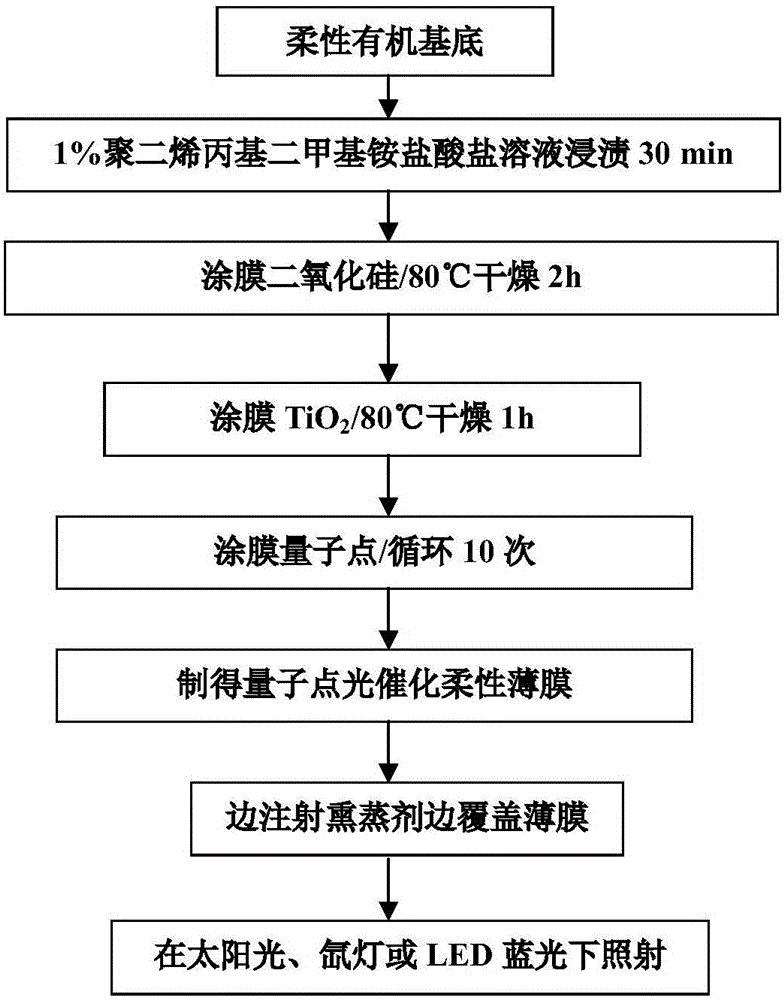

Method used

Image

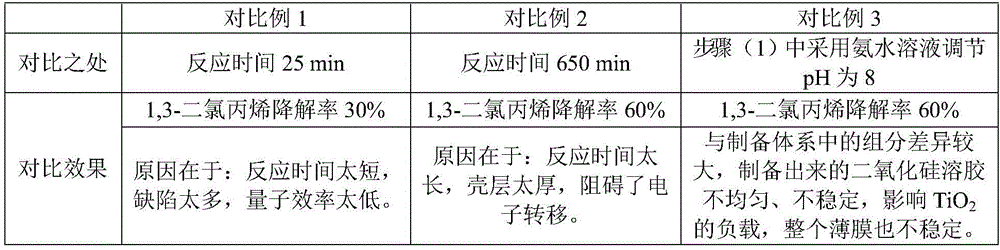

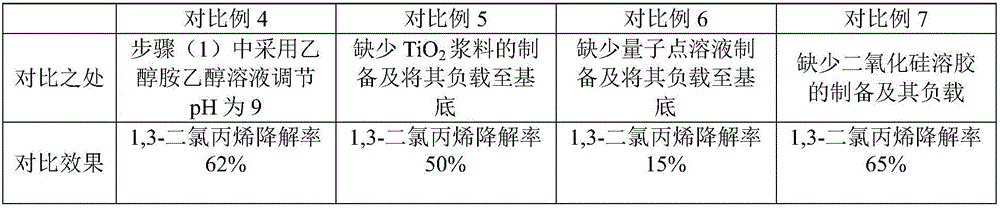

Examples

Embodiment 1

[0043] This embodiment provides a method for preparing a quantum dot photocatalytic film, which is characterized in that the method includes the following steps:

[0044] (1) The preparation of the silica sol is as follows: mix TEOS, ethanol and deionized water at a volume ratio of 5:1:1.2, and stir for 30 minutes; add 37% hydrochloric acid (with a volume ratio of 0.005:1 to ethanol) ), the catalytic hydrolysis mixture is continuously stirred; then the above solution is diluted 20 times with ethanol, and stirring is continued for 24h at room temperature; finally, the pH is adjusted to 8 with ethanolamine ethanol solution.

[0045] (2) The TiO 2 The preparation of the slurry is as follows: TiO 2 The powder was sintered in a muffle furnace at 450°C for 30 minutes; 0.22g / mL TiO was prepared 2 Ethanol dispersion and ultrasound; continue to add TTIP (with TiO 2 The ratio of the amount of the substance is 0.036:1) Continue to sonicate for 60 minutes, and further centrifuge to obtain trans...

Embodiment 2

[0053] Embodiment 2 is a variation of Embodiment 1, and the only change is: in step (3), the reaction time is 420 min.

[0054] Before application, first prepare the prepared CIS / ZnS:Al-TiO 2 (420min) Photocatalytic film (substrate thickness 0.1mm), use the injection method commonly used in agriculture to apply 1,3-dichloropropene to the soil, and cover the surface of the soil while injecting the drug to prevent the volatilization of the drug solution. Use soil Squeeze all around. Of which TiO 2 The layer is composed of transparent and opaque layers, low temperature: 5°C~15°C, irradiated under sunlight for 35h, and the degradation rate of 1,3-dichloropropene in the film is measured. The degradation rate is 99%.

Embodiment 3

[0056] Embodiment 3 is a variation of embodiment 1, and the only change is: in step (3), the reaction time is 420 min.

[0057] Before application, first prepare the prepared CIS / ZnS:Al-TiO 2 (420min) Photocatalytic film (substrate thickness 0.1mm), use the injection method commonly used in agriculture to apply 1,3-dichloropropene to the soil, and cover the surface of the soil while injecting the drug to prevent the volatilization of the drug solution. Use soil Squeeze all around. Of which TiO 2 The layer is composed of transparent and opaque layers, with a medium temperature: 15°C to 25°C, irradiated under sunlight for 20 hours, and the degradation rate of 1,3-dichloropropene in the film is measured. The degradation rate is 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com