Nano heterogeneous Fenton catalyst with alginate core coated with copper/magnetic Fe3O4 and preparation method of Nano heterogeneous Fenton catalyst

An alginate and outer coating technology is applied in the field of heterogeneous Fenton catalyst and its preparation, which can solve the problems of loss, difficult separation of catalyst ions, etc., and achieves increased oxidation capacity, reduced Fenton mud, and good biological phase. Capacitive and Environmentally Friendly Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

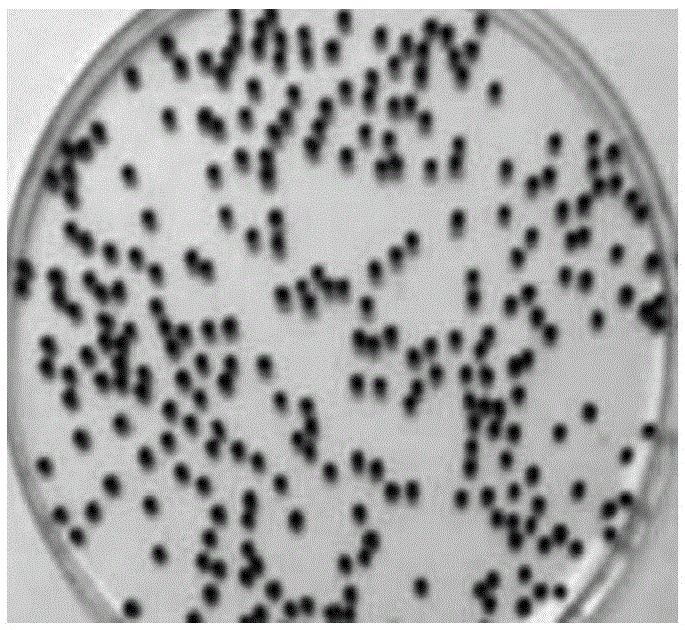

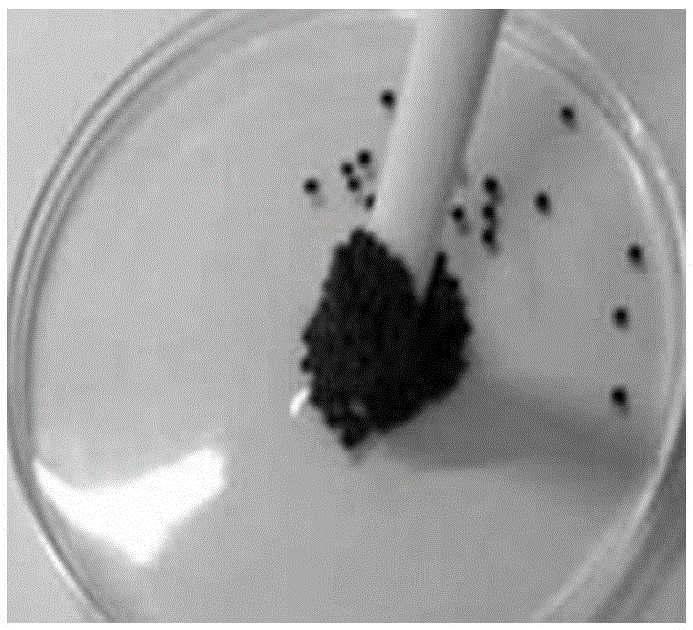

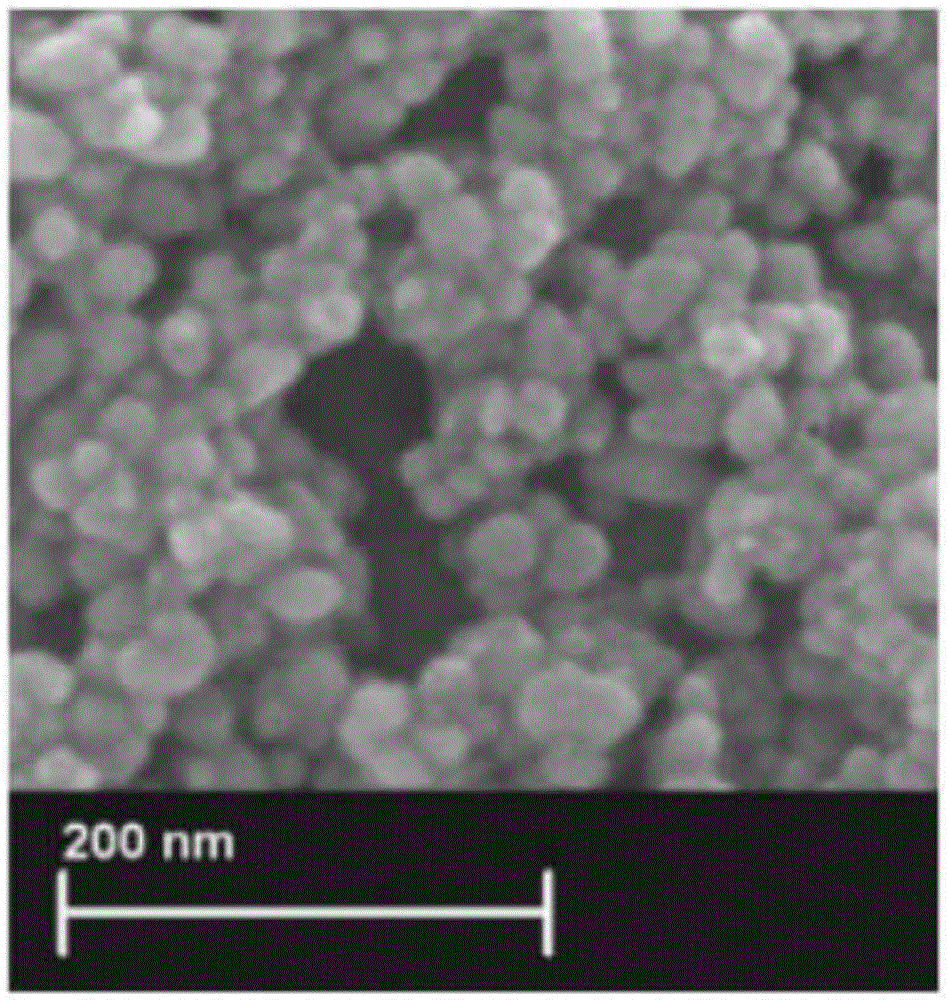

[0021] Specific implementation mode 1: the alginate core of the present embodiment is coated with copper / magnetic Fe 3 o 4 The nano-heterogeneous Fenton-like catalyst is based on sodium alginate as the core, and the core is coated with Fe 3 o 4 Magnetic nanoparticles and spherical particles of copper chloride, the particle size is 1 to 1.5 mm, Fe 3 o 4 The particle diameter of the magnetic nanoparticles is 15-35 nanometers.

specific Embodiment approach 2

[0022] Specific embodiment two: Alginate core outer coating copper / magnetic Fe described in specific embodiment one 3 o 4 The preparation method of the nanometer heterogeneous Fenton-like catalyst is carried out in the following steps:

[0023] 1. Mix the ferrous salt and the ferric salt according to the molar ratio of 1: (2~3), then heat up to 30~70°C, and add an alkali solution with a concentration of 1~5mol / L under stirring conditions as Precipitant, stirring and reacting for 1 to 1.5 hours, static precipitation, removing the supernatant, washing the precipitate with ultrapure water until the pH is neutral, and then ultrasonically dispersed for 5 to 10 minutes, then transferred to a sample bottle for storage, and obtained Magnetic nano-Fe 3 o 4 Dispersions;

[0024] Two, the sodium alginate solution is added to the magnetic nano-Fe prepared in step one 3 o 4 In the dispersion liquid and mixed uniformly, it is prepared into a suspension slurry;

[0025] 3. Add the sus...

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the ferrous salt and the ferric salt are sulfate, chloride or phosphate. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com