A kind of amino acid ionic liquid molecule and its preparation method and application

A technology for ionic liquids and amino acids, which is applied in the field of preparation of amino acid ionic liquids, to achieve the effects of environmental friendliness, low cost, easy acquisition, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

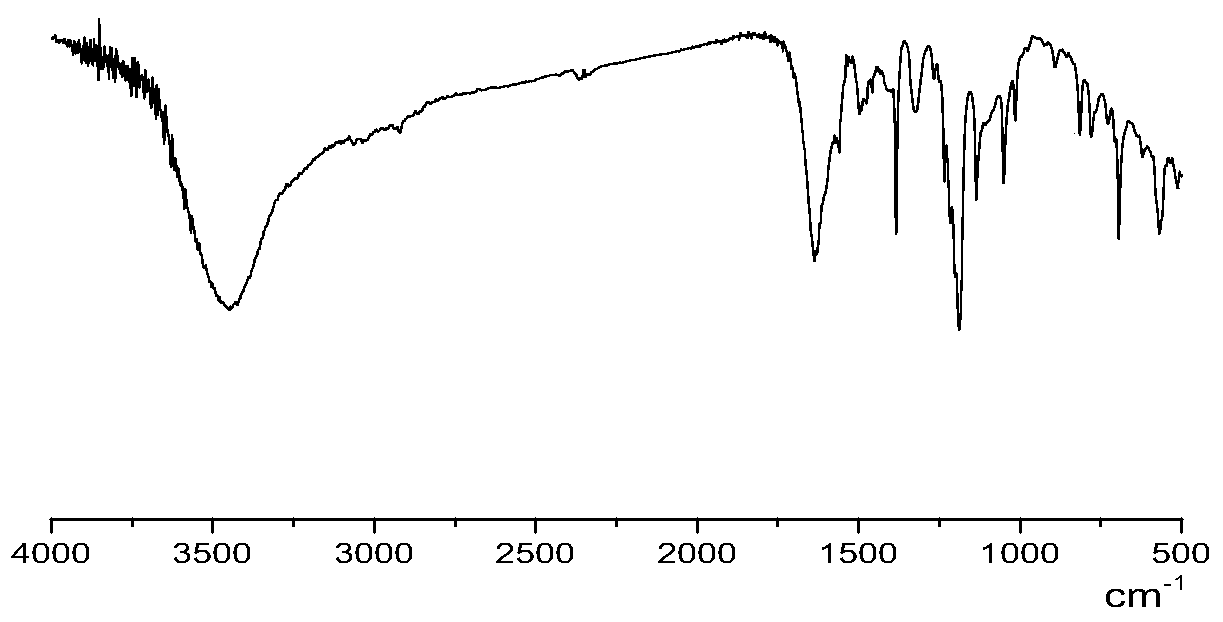

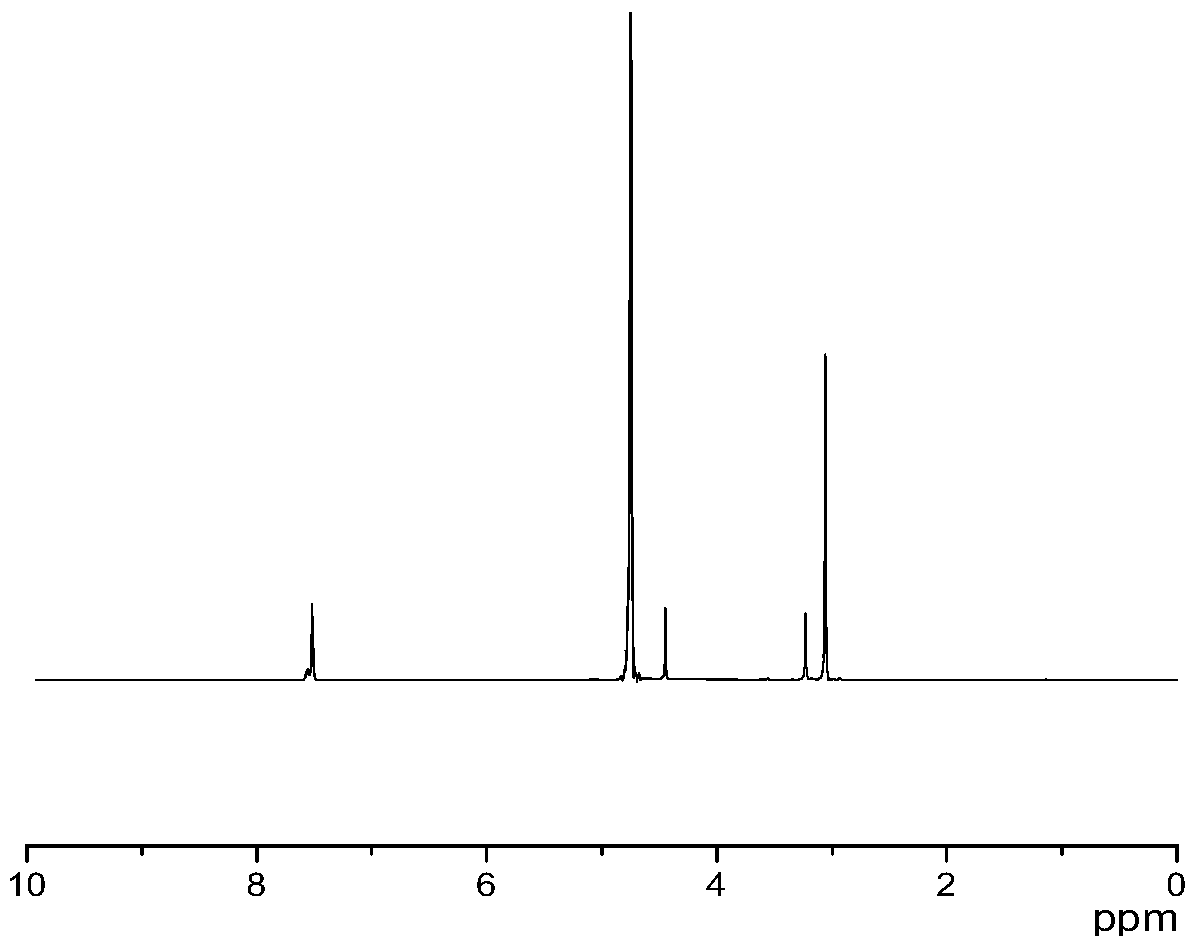

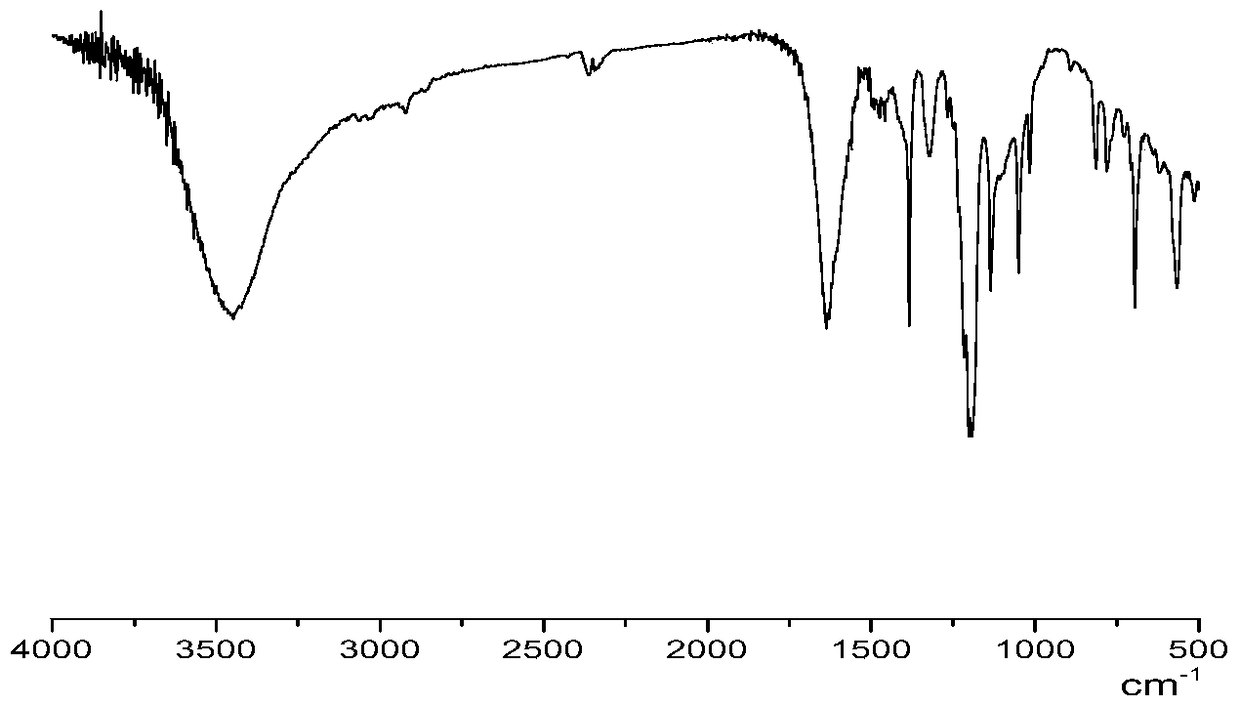

Image

Examples

Embodiment 1

[0037] Transfer a certain amount of C into a 250mL three-neck flask 1 ~C 20 alkane amine (water or alcohol) solution, and then drop propylene oxide (propylene oxide and alkane amine are added in equimolar amounts) with a dropping funnel, and the dropwise addition is completed in about 30 minutes. React for 2-8 hours. After the reaction is over, raise the temperature of the product mixture to 35°C, and steam the unreacted propylene oxide to obtain the tertiary aminated product solution. Add an equimolar amount of halogenated hydrocarbon according to the amount of the tertiary aminated product. (such as benzyl chloride), stir the reaction at constant temperature (40-80°C) for a certain period of time, and end the reaction. The product mixture is layered, and the lower layer is unreacted benzyl chloride. Remove traces of benzyl chloride that may remain in the water layer, remove the ether layer, and vacuum-dry the resulting solution to obtain the quaternary ammonium salt product...

Embodiment 2

[0041] Transfer a certain amount of C into a 250mL three-neck flask 1 ~C 15 alkane amine (water or alcohol) solution, then drop propylene oxide (propylene oxide and alkane amine in 2:1 molar amount) with a dropping funnel, and drop it for about 30 minutes, keep stirring at low temperature (0-5°C) The reaction was continued for 2-8 hours. After the reaction, the temperature of the product mixture was raised to 35°C, and the unreacted propylene oxide was evaporated to obtain the tertiary aminated product solution. Equimolar amounts of halogen were added according to the amount of the tertiary aminated product. After substituting a hydrocarbon (such as benzyl chloride), stir the reaction at a constant temperature (40-80°C) for a certain period of time, and end the reaction. The product mixture is layered, and the lower layer is unreacted benzyl chloride. After separation, the product solution is extracted twice with ether , to remove traces of benzyl chloride that may remain in ...

Embodiment 3

[0045] Transfer a certain amount of C into a 250mL three-neck flask 1 ~C 15 alkane amine (water or alcohol) solution, then drop propylene oxide (propylene oxide and alkane amine in 3:1 molar amount) with a dropping funnel, and drop it for about 30 minutes, keep stirring at low temperature (0-5°C) The reaction was continued for 2-8 hours. After the reaction, the temperature of the product mixture was raised to 35°C, and the unreacted propylene oxide was evaporated to obtain the tertiary aminated product solution. Equimolar amounts of halogen were added according to the amount of the tertiary aminated product. After substituting a hydrocarbon (such as benzyl chloride), stir the reaction at a constant temperature (40-80°C) for a certain period of time, and end the reaction. The product mixture is layered, and the lower layer is unreacted benzyl chloride. After separation, the product solution is extracted twice with ether , to remove traces of benzyl chloride that may remain in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com