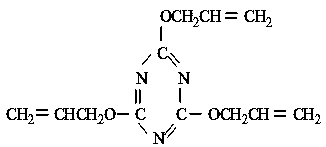

A kind of preparation method of triallyl cyanurate

A technology of triallyl ester and cyanuric acid, applied in the direction of organic chemistry, etc., can solve problems such as poor operating environment, impact on the next reaction, and high toxicity of the solvent toluene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a cooled 500ml reactor, add 61.8g (1.065mol) of allyl alcohol and 120ml of 6 # Solvent oil, after stirring and cooling to below 15°C, add 65.5g (0.355mol) of cyanuric chloride. Under the condition of vigorous stirring and cooling, 142 g of 1.42 mol of 40% sodium hydroxide solution was added dropwise. In the first stage, 70% sodium hydroxide solution was added dropwise, the temperature was controlled at 20°C, and the dropping time was about 1.5 hours. At this time, the cooling medium was removed, and the remaining sodium hydroxide solution was added dropwise in the second stage within 0.5 hours, so that the temperature naturally increased to 40°C. Insulate and stir the reaction at 40°C for 4 hours. After the reaction, the reaction solution is transferred to the liquid separator, add 120ml of water, stir and let it stand for stratification, drain the waste water in the lower layer, and then wash the organic layer with 100ml of water at 30°C. times, wash until neutral....

Embodiment 2

[0024] In a cooled 500ml reactor, add 68.0g (1.171mol) of allyl alcohol and 120ml of 6 # Solvent oil, after stirring and cooling to below 15°C, add 65.5g (0.355mol) of cyanuric chloride. Under the condition of strong stirring and cooling, start to drop 200g of 1.60mol 32% sodium hydroxide solution, in the first stage, add dropwise 75% sodium hydroxide solution, the temperature is controlled at 25°C, and the dropping time is about 1.5 hours At this time, the cooling medium was removed, and the remaining sodium hydroxide solution was added dropwise within 0.5 hours in the second stage, so that the temperature naturally increased to 35°C. Insulate and stir the reaction at 35°C for 3.5 hours. After the reaction, move the reaction liquid to a liquid separator, add 120ml of water, leave to separate after stirring, drain the waste water in the lower layer, and then wash the organic layer with 100ml of water at 30°C. times, wash until neutral. The organic layer enters the distiller,...

Embodiment 3

[0026] In a cooled 500ml reactor, add 68.0g (1.171mol) of allyl alcohol and 120ml of toluene, stir and cool to below 15°C, then add 65.5g (0.355mol) of cyanuric chloride. Under the condition of vigorous stirring and cooling, 160g of 1.60mol 40% sodium hydroxide solution was added dropwise, in the first stage, 70% sodium hydroxide solution was added dropwise, the temperature was controlled at 15°C, and the dropping time was about 1.5 hours At this time, the cooling medium was removed, and the remaining sodium hydroxide solution was added dropwise in the second stage within 0.5 hours, so that the temperature naturally rose to 30°C. Insulate and stir the reaction at 30°C for 4 hours. After the reaction, move the reaction liquid to a liquid separator, add 120ml of water, leave to separate after stirring, drain the waste water in the lower layer, and then wash the organic layer with 100ml of water at 30°C. times, wash until neutral. The organic layer enters the distiller, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com