Preparation method of polysubstituted thiapyran diindyl derivative

A technology of indole derivatives and multi-substitution is applied in the field of preparation of multi-substituted thiopyranoindole derivatives, which can solve the problems of difficulty in synthesizing multi-substituted thiopyranoindole derivatives, expensive catalytic metals, and many synthesis steps. , to achieve the effect of easy purification of the product, simple synthesis method and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: 11-phenylbenzothiopyranoindole (R in structural formula I 9 = phenyl)

[0035] Add o-alkynyl isothiocyanate (0.5mmol, 117mg), diaryl hyperiodonium salt (0.75mmol, 313mg) and copper salt (0.05mmol), potassium carbonate (70mg, 0.5mmol) to a 10mL Shrek tube , after replacing the nitrogen gas three times, 2.5 mL of dichloroethane was added and reacted at 50° C. for 4 h. After the reaction system was cooled, 5 mL of saturated NaHCO was added 3 The solution quenched the reaction, and then extracted three times with 30 mL ethyl acetate, combined the organic phases, washed with saturated NaCl and washed with anhydrous MgSO 4 Dry for 30 minutes, filter, and concentrate the filtrate with a rotary evaporator to obtain a crude product. The crude product was separated by column chromatography (200-300 mesh silica gel) to obtain 100 mg of the red solid product 11-phenylthiopyranoindole with a purity greater than 99%, and the isolated yield was 64%.

[0036] Structural ...

Embodiment 2

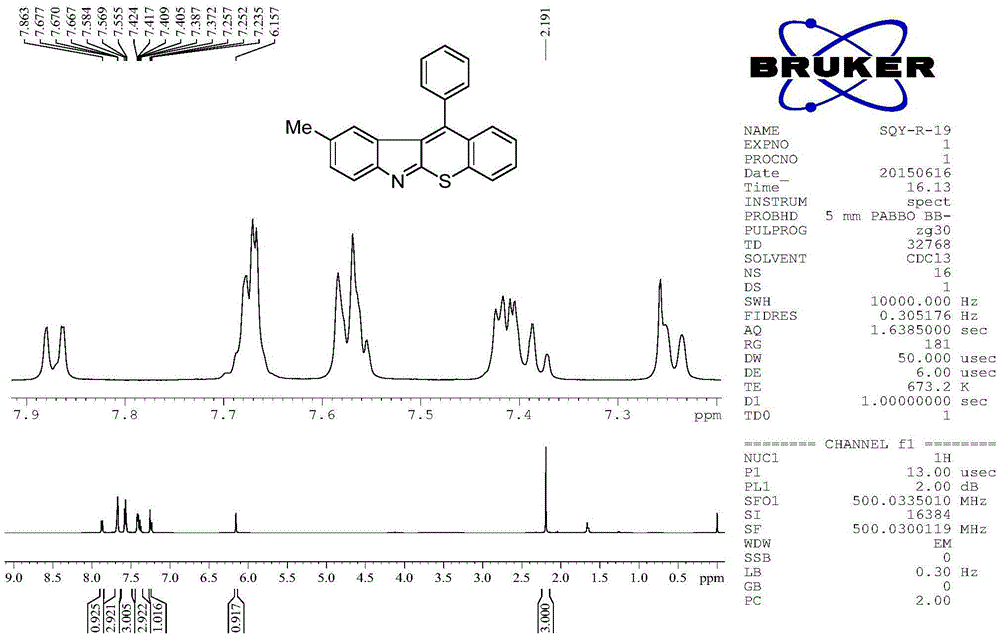

[0041] Embodiment 2: 3-methyl-11-phenylbenzothiopyranoindole (R in structural formula I 6 = methyl, R 9 = phenyl)

[0042] Add o-alkynyl isothiocyanate (0.5mmol, 124mg), diaryl hyperiodonium salt (0.75mmol, 313mg) and copper salt (0.05mmol), potassium carbonate (70mg, 0.5mmol) to a 10mL Shrek tube , after replacing the nitrogen gas three times, 2.5 mL of dichloroethane was added and reacted at 50° C. for 4 h. After the reaction system was cooled, 5 mL of saturated NaHCO was added 3 The solution quenched the reaction, and then extracted three times with 30 mL ethyl acetate, combined the organic phases, washed with saturated NaCl and washed with anhydrous MgSO 4 Dry for 30 minutes, filter, and concentrate the filtrate with a rotary evaporator to obtain a crude product. The crude product was separated by column chromatography (200-300 mesh silica gel) to obtain 99 mg of 3-methyl-11-phenylbenzothiopyranoindole as a red solid product with a purity of more than 99%, and the isol...

Embodiment 3

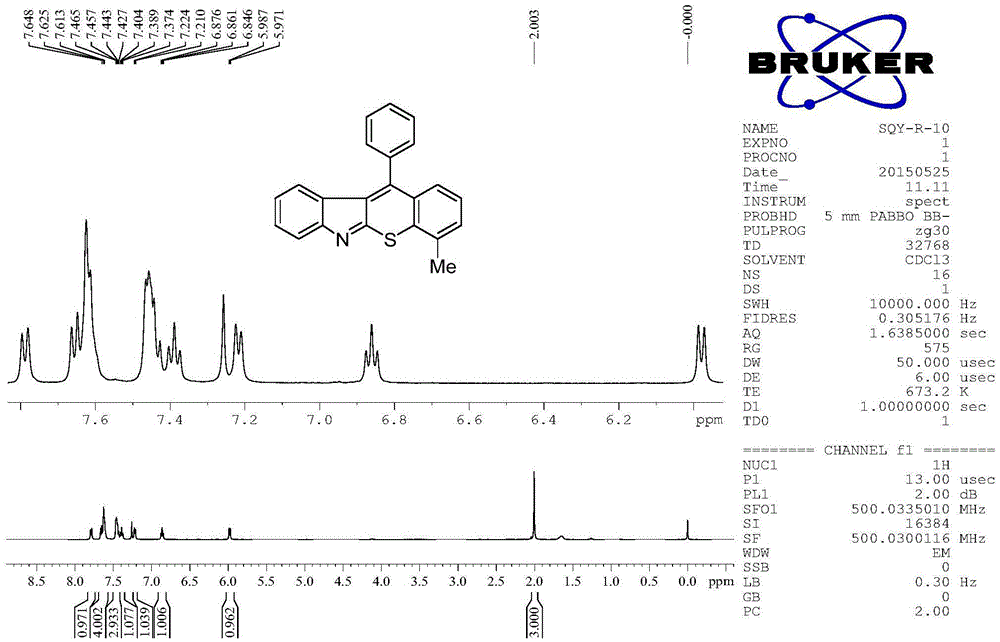

[0048] Embodiment 3: 2-methyl-11-phenylbenzothiopyranoindole (R in structural formula I 7 = methyl, R 9 = phenyl)

[0049] Add o-alkynyl isothiocyanate (0.5mmol, 124mg), diaryl hyperiodonium salt (0.75mmol, 313mg) and copper salt (0.05mmol), potassium carbonate (70mg, 0.5mmol) to a 10mL Shrek tube , after replacing the nitrogen gas three times, 2.5 mL of dichloroethane was added and reacted at 50° C. for 4 h. After the reaction system was cooled, 5 mL of saturated NaHCO was added 3 The solution quenched the reaction, and then extracted three times with 30 mL ethyl acetate, combined the organic phases, washed with saturated NaCl and washed with anhydrous MgSO 4 Dry for 30 minutes, filter, and concentrate the filtrate with a rotary evaporator to obtain a crude product. The crude product was separated by column chromatography (200-300 mesh silica gel) to obtain 100 mg of a red solid product 2-methyl-11-phenylbenzothiopyranoindole with a purity of more than 99%, and the isolat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com