Adhesive layer and adhesive film

An adhesive layer and adhesive technology, applied in the directions of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of reduced visibility, noise effects, etc. Effects of workability, durability and reworkability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

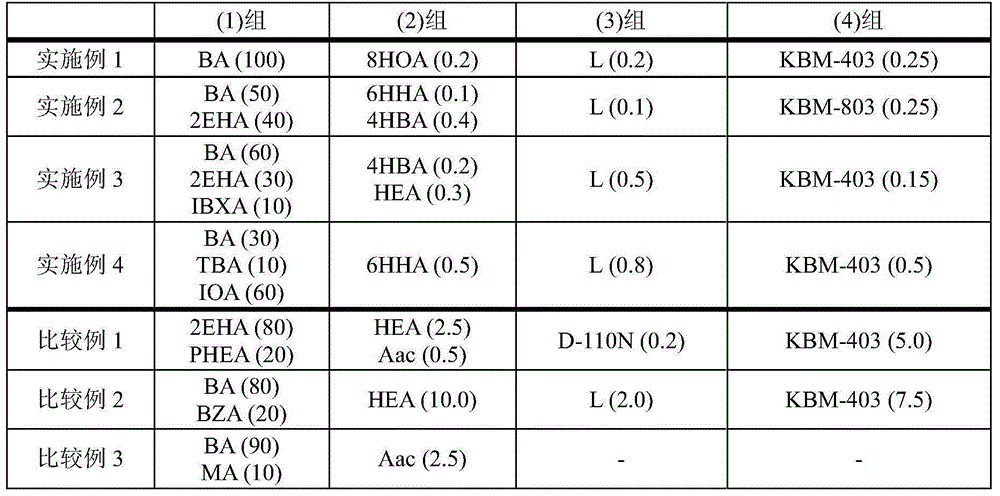

[0080] Nitrogen gas was introduced into a reaction device equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen introduction pipe, and the air in the reaction device was replaced with nitrogen gas. Thereafter, 100 parts by weight of butyl acrylate and 0.2 parts by weight of 8-hydroxyoctyl acrylate were added to the reaction device, and 60 parts by weight of a solvent (ethyl acetate) were added simultaneously. Thereafter, 0.1 part by weight of azobisisobutyronitrile was added dropwise as a polymerization initiator over 2 hours, and reacted at 65° C. for 6 hours to obtain acrylic polymer solution 1 used in Example 1. A part of the acrylic polymer was collected and used as a measurement sample for the acid value described later.

Embodiment 2~4 and comparative example 1~3

[0082] The composition of the monomers was as described in the (1) group and (2) group of Table 1, respectively, except that, it was carried out in the same manner as the acrylic polymer solution 1 used in the above-mentioned Example 1, and Examples 2-4 were obtained. and the acrylic polymer solutions used in Comparative Examples 1-3.

[0083]

[0084] [Example 1]

[0085] To the acrylic polymer solution 1 of Example 1 produced as described above, 0.2 parts by weight of Coronate L (a 75% ethyl acetate solution of a trimethylolpropane (TMP) adduct of a toluene diisocyanate (TDI) compound) was added, 0.05 parts by weight of KBM-403 (3-glycidoxypropyltrimethoxysilane) was stirred and mixed to obtain the adhesive composition of Example 1. After coating this adhesive composition on a release film (a polyterephthalic acid (PET) film coated with a silicone resin), drying at 90° C. to remove the solvent, and drying at 23° C. Aging was carried out for 7 days in an atmosphere of 50%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com