Non-probabilistic reliability pneumatic structure coupling optimization design method for hypersonic velocity three-dimensional wing

A hypersonic, optimized design technology, applied in computing, sustainable transportation, special data processing applications, etc., can solve problems such as low computational efficiency, imperfect subjectivity theory, and unreliable computational results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

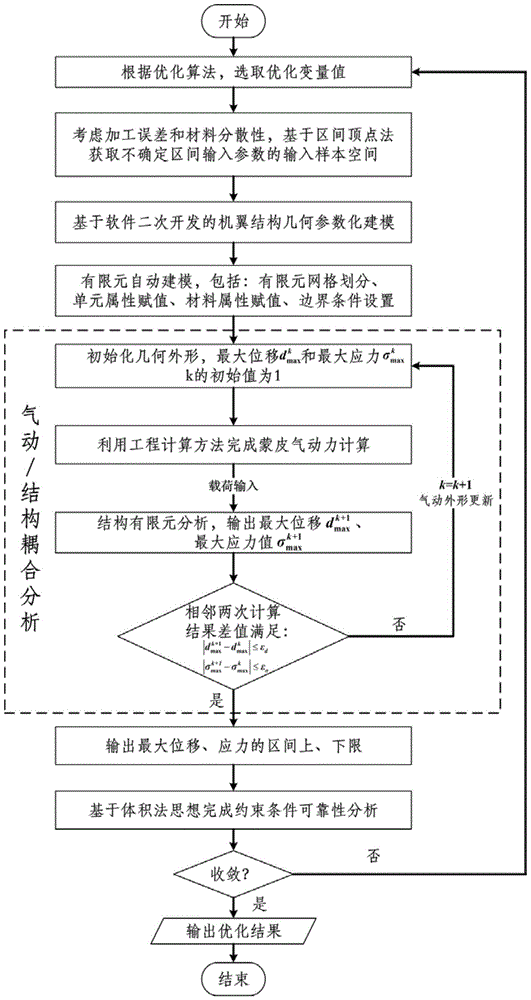

[0066] In order to understand more fully the characteristics of the invention and its applicability to engineering practice, the present invention aims at such as Figure 4 The hypersonic wing structure shown is designed by non-probabilistic reliability optimization of aerodynamic structure coupling. The wing consists of three parts: a titanium alloy frame with beams and ribs, a honeycomb sandwich structure filled between the beams and ribs, and a skin structure attached to the surface of the wing. This embodiment aims at the wing structure of a typical hypersonic aircraft, fully considers the coupling effect of aerodynamics and structure, utilizes the method disclosed in the present invention, takes the beam and rib thickness as the design variable, the non-probabilistic reliability index as the constraint, and the weight of the wing As the goal, realize the non-probabilistic reliability optimization design of the wing structure. Table 1 gives the uncertainty information of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com