Solar cell structure

A solar cell and electrode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of few carrier transport and absorption improvements, increase external quantum efficiency, increase light utilization, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

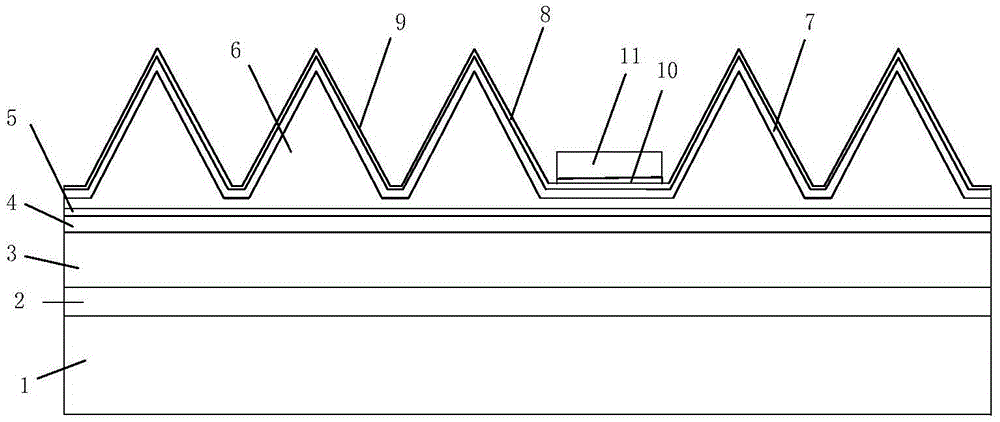

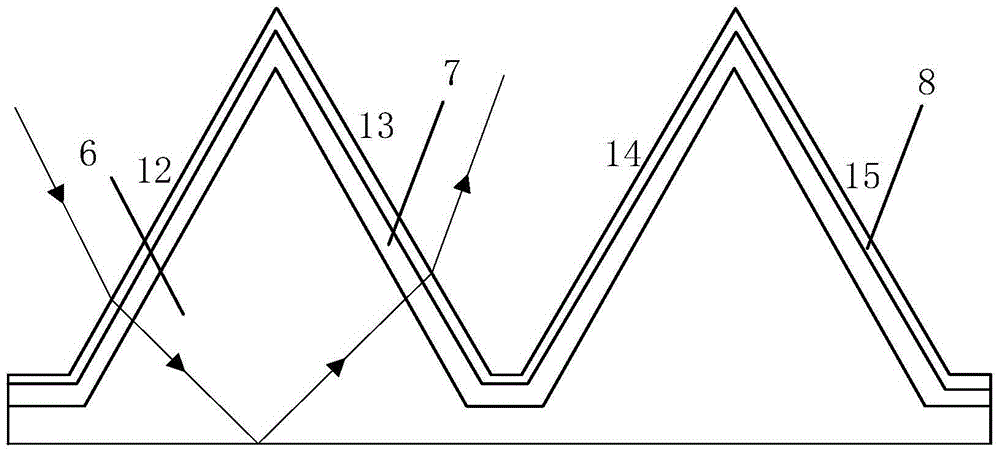

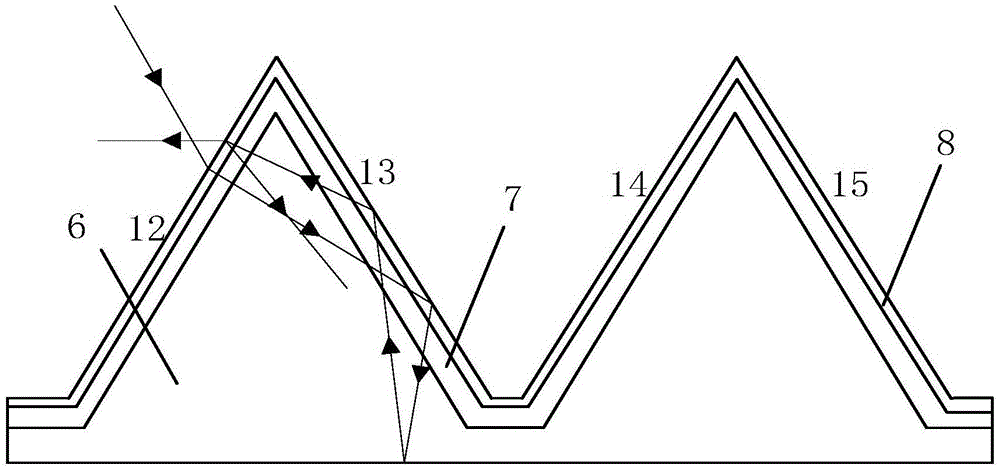

[0019] Such as figure 1 As shown, the present invention provides a solar cell structure, comprising: a back electrode 2, a buffer layer 3, a background layer 4, a reflection layer 5, a base layer 6, an emission layer 7, a window layer 8, Anti-reflection layer 9, contact layer 10 and gate line electrode 11; Wherein, described base layer 6 comprises first base layer and second base layer, and described second base layer is positioned on described first base layer, and the shape of described second base layer Convex in the shape of multiple side-by-side triangular prisms. Preferably, the contact layer 10 and the gate line electrode 11 are located in the depression between the triangular prism-shaped protrusions on the anti-reflection layer 9 . Wherein preferably, the contact layer 10 and the grid line electrode 11 are located in the recesses separated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com